3D printing filling design method based on force flow pipe load path

A technology of 3D printing and design method, applied in the field of 3D printing, can solve the problems of reducing the strength and weakness of parts, and achieve the effect of improving the performance of parts, taking into account the accuracy and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

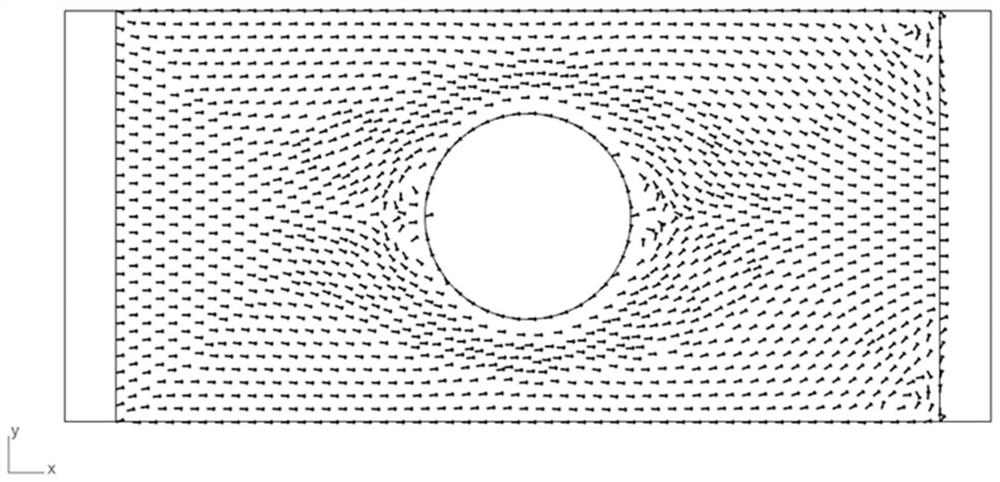

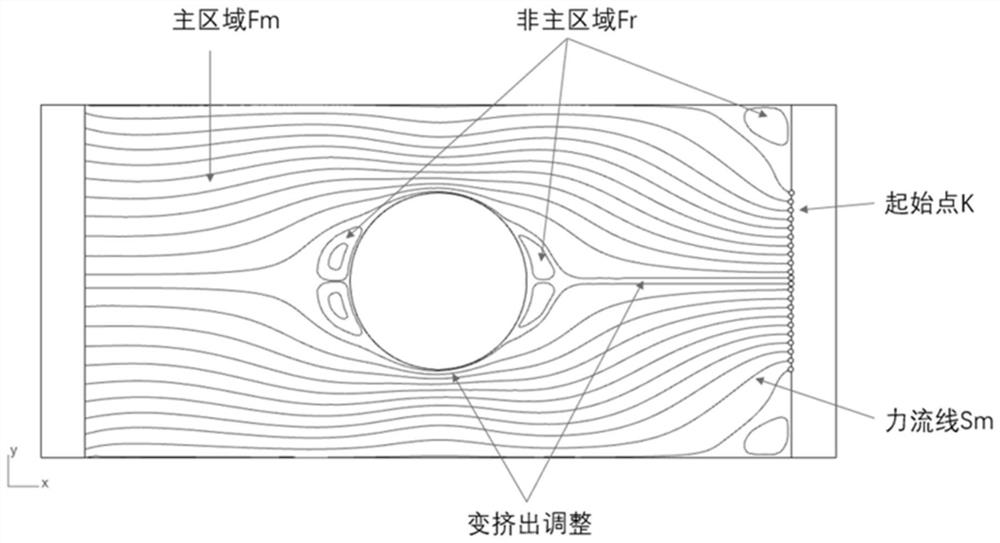

[0045] The present invention proposes a 3D printing filling design method based on the load path of the force flow tube, and uses extrusion 3D printing technology for processing and manufacturing. There are many ways to define the load path. In this example, the force flow tube is specifically used. The load direction represented by (force tube), the definition of this load path can ensure constant load transmission in the main load direction, solve the local weakness caused by hole defects and other problems, and finally improve the overall strength of the part. The specific steps are as follows:

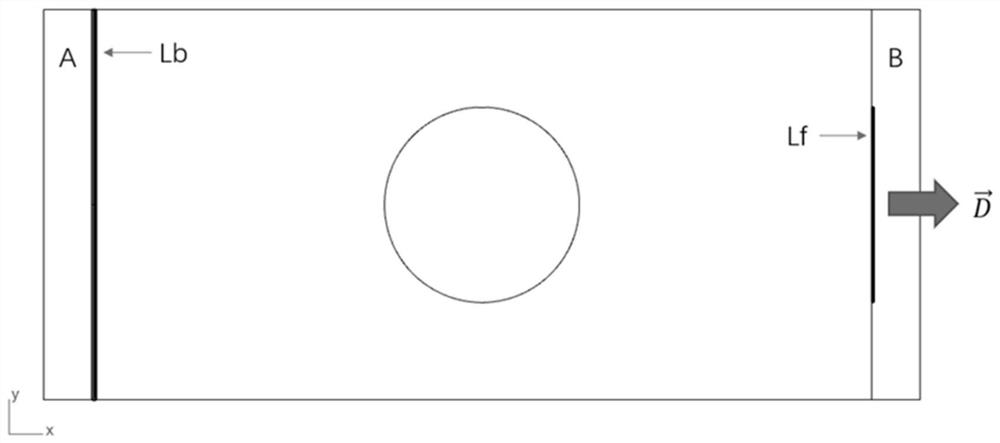

[0046] (1) Set the main force direction of the part According to the direction of the main force and the direction of the rectangular coordinate system Relationship: Create a computer 3D model;

[0047] (2) Define the part clamping area A and the load application area B, and determine the constraint boundary Lb and the load boundary (or load point) Lf, such as figure 2 shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com