Flexible sensor and preparation method thereof

A flexible sensor and sensor technology, applied in the field of sensors, can solve the problems of poor stretching effect of the base layer, poor stretching effect, and limited application range of the base layer, so as to avoid limitations, avoid process steps, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

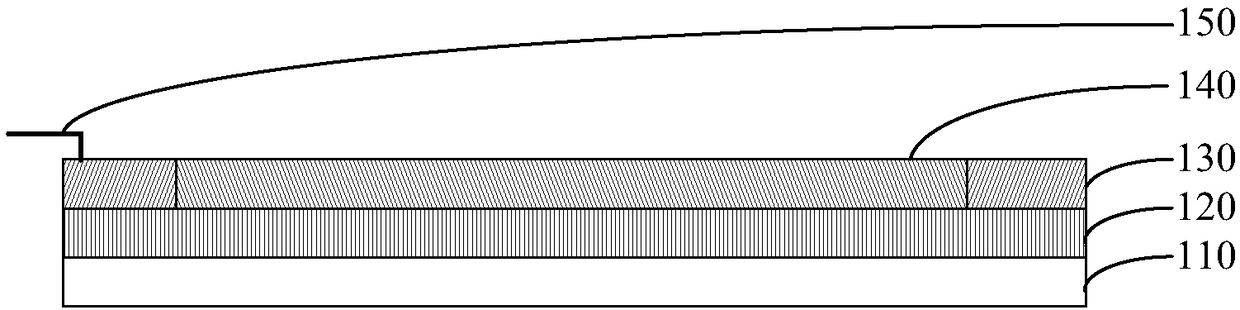

[0032] see figure 1 , Embodiment 1 of the present invention provides a flexible sensor, including: a base layer 110 formed of flexible and plastic rubber, a conductive layer 120 located on the base layer 110, a conductive contact 130 located on the conductive layer 120 and a passivation layer 140 and a wire 150 connected to the conductive layer 120 through the conductive contact 130 for conducting the induced current.

[0033] Wherein, the preparation material of the rubber includes PVC (Polyvinyl chloride, no polyvinyl chloride) or rubber or TPR (Thermo-Plastic-Rubber material, thermoplastic rubber). The preparation material of the above-mentioned conductive layer includes multi-walled carbon nanotubes. The preparation material of the above-mentioned conductive contacts includes silver paste. The preparation material of the passivation layer includes polyimide. The preparation material of the above-mentioned wire includes metal copper.

[0034] Due to the softness, ductil...

Embodiment 2

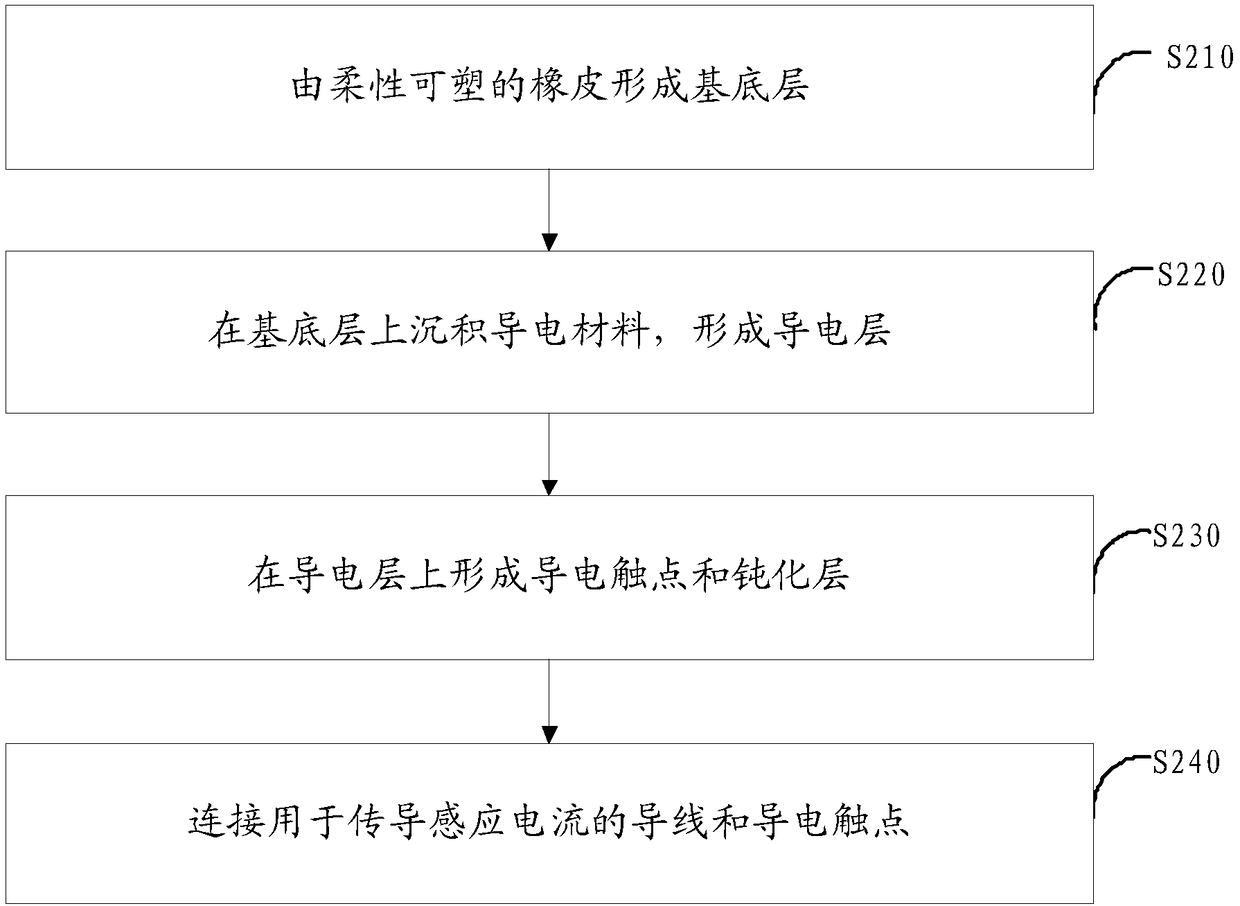

[0037] see figure 2 , Embodiment 2 of the present invention provides a method for manufacturing the flexible sensor described in Embodiment 1, the method comprising:

[0038] S210, forming the base layer 110 from a flexible and plastic rubber;

[0039] S220, depositing a conductive material on the base layer 110 to form a conductive layer 120;

[0040] S230, forming a conductive contact 130 and a passivation layer 140 on the conductive layer 120;

[0041] S240 , connecting the wire 150 for conducting the induced current and the conductive contact 130 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com