A matching research method for the spherical contact surface of the generator bearing seat and the bearing bush

A generator bearing and bearing seat technology, applied in the manufacture of motor generators, electromechanical devices, electrical components, etc., can solve the problems of labor waste, low production efficiency, rework, etc., to avoid rework again, improve work efficiency, and clear standards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

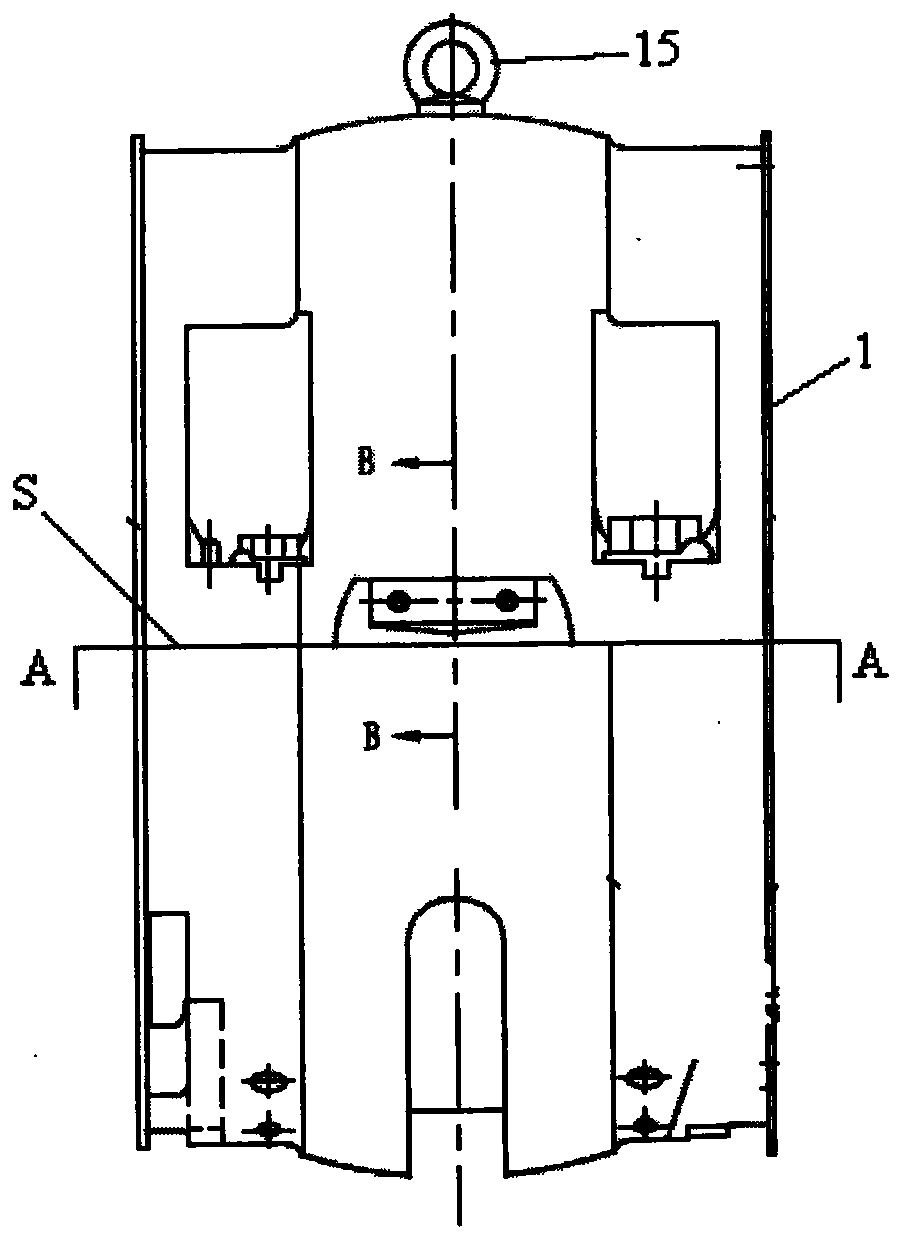

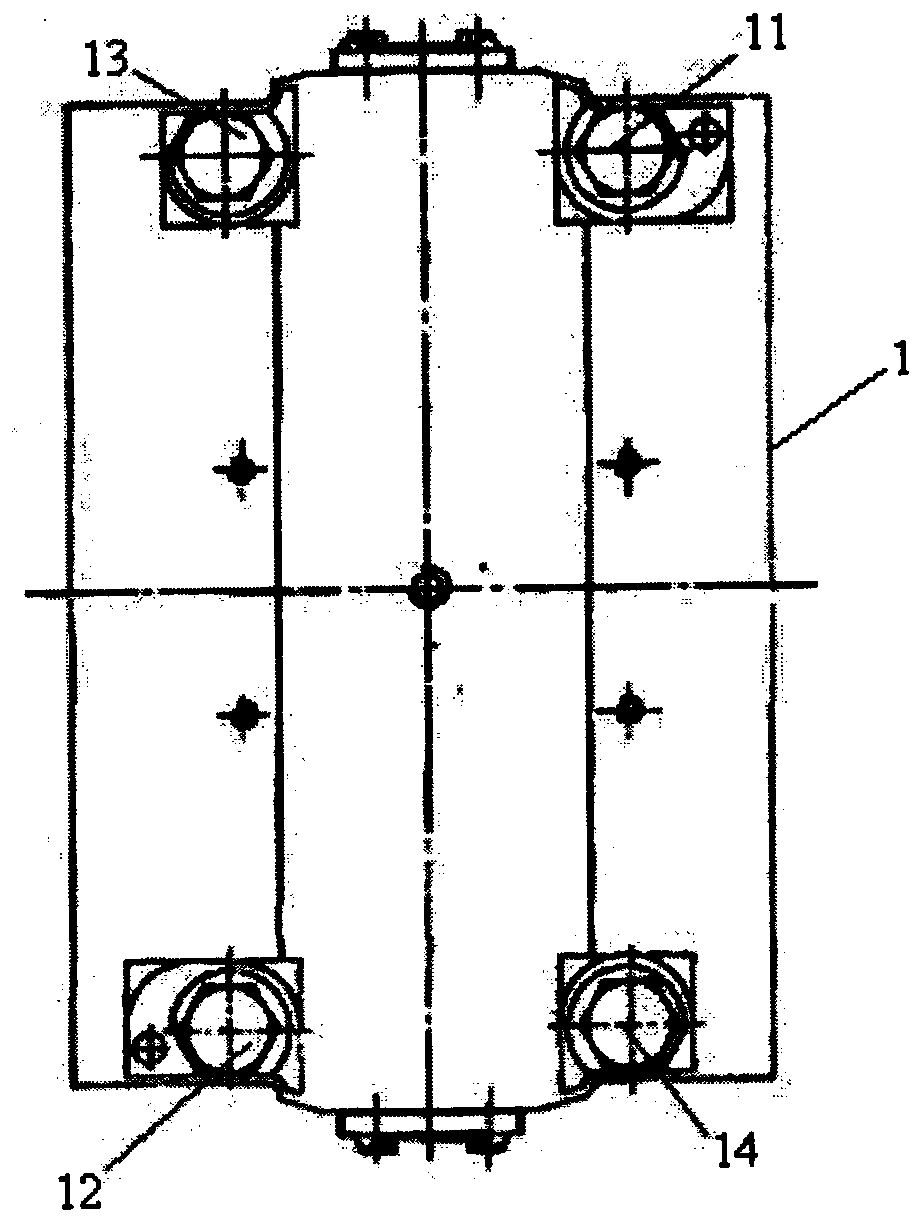

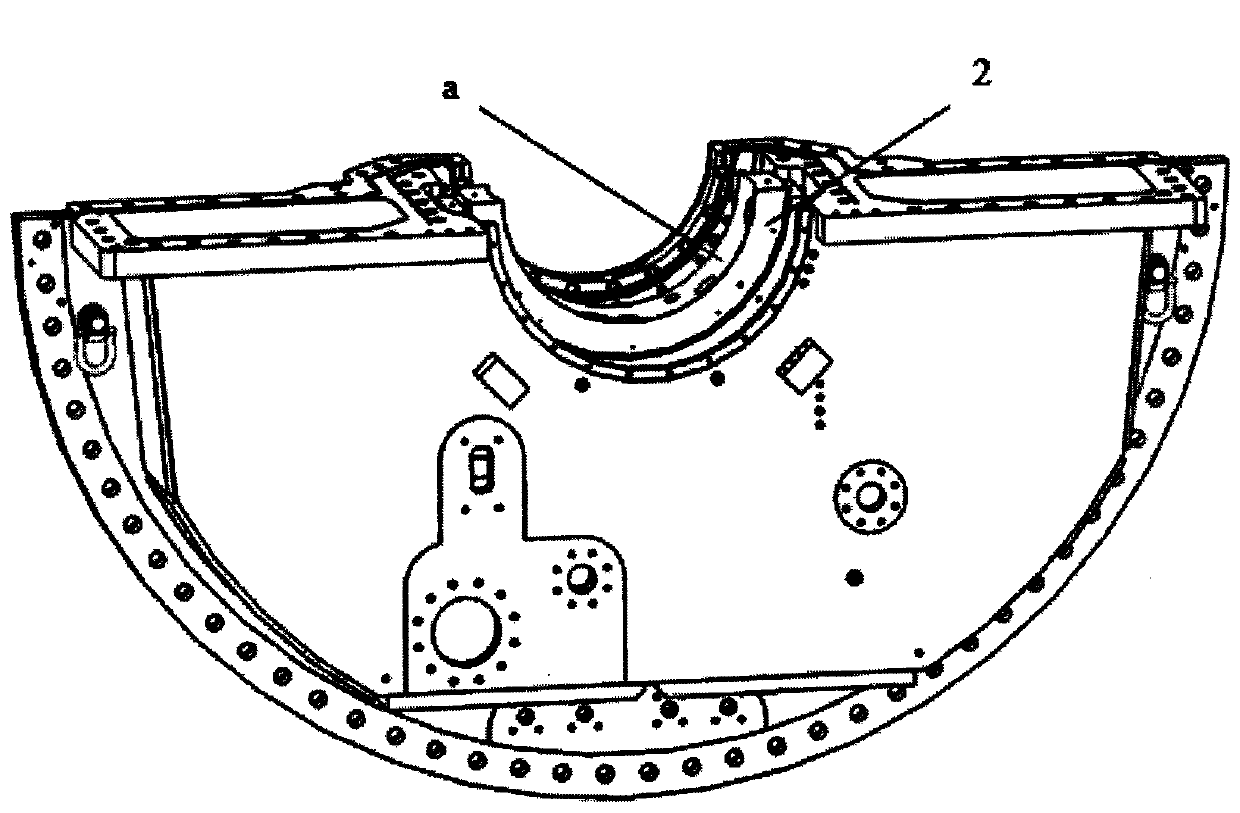

[0030] A matching research method for the spherical contact surface of a generator bearing seat and a bearing bush:

[0031] Step 1: Install the bearing bush: disassemble the bearing bush 1 after the processing is completed, clean the mid-section surface S of the bearing bush 1, level it with oil and then assemble it. The assembly is completed as follows: figure 1 shown; as figure 2 As shown, when the bearing bush 1 is assembled, the left side is the empty side, and the right side is the hydrogen side. The tightening sequence of the bolts on the middle split surface S is: bolt one 11 on the upper right, bolt two 12 on the lower left, and bolt three 13 on the upper left , Bolt four 14 on the lower right; the four bolts are tooling bolts, and the tightening torque of the bolts is 1385N·m.

[0032] Step 2: Lifting the bearing: use the sling to lift the bearing 1; the top of the bearing 1 is equipped with a lifting handle 15, and when lifting, keep the bearing 1 in a vertical st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com