Scrophularia ningpoensis origin processing technology

A processing technology and origin processing technology, applied in the field of origin processing technology of scrophularia, can solve the problems of long processing time and unstable quality of scrophularia, and achieve the effects of short time, good sweating effect, and uniform drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

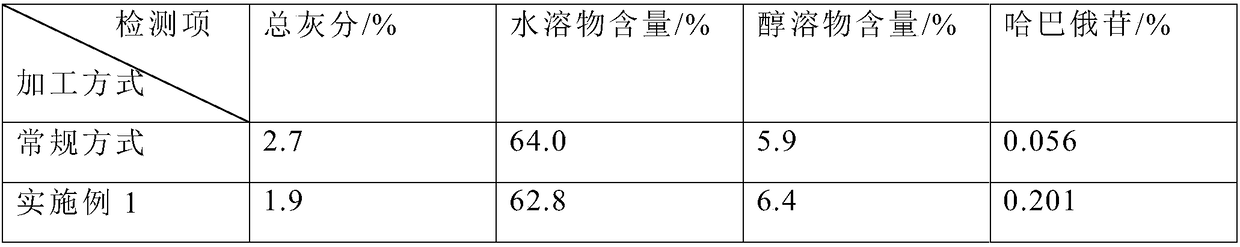

Embodiment 1

[0033] The origin processing technology of Scrophulariaceae includes the following steps;

[0034] S1. Purchasing fresh and complete Scrophulariae scrophulariae, the length of each Scrophulariae scrophulariae is not less than 15 cm;

[0035] S2, shaking off excess soil and impurities on the Scrophulariaceae;

[0036] S3, grading Scrophulariae according to the size of the diameter of each scrophulariaceae, and then cleaning the graded Scrophulariaceae;

[0037] S4, putting the graded Scrophulariaceae into an oven for pre-drying treatment, the pre-drying treatment is divided into the following six stages;

[0038] The first stage is 9 hours; the temperature in the oven is 34 degrees Celsius and the relative humidity is 26;

[0039] The second stage is 9 hours; the temperature in the oven is 37 degrees Celsius and the relative humidity is 28;

[0040] The third stage is 14 hours; the temperature in the oven is 41 degrees Celsius and the relative humidity is 30;

[0041] The f...

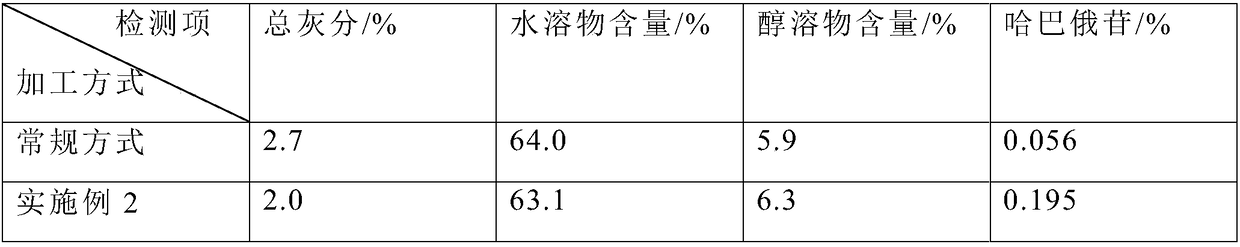

Embodiment 2

[0066] The origin processing technology of Scrophulariaceae includes the following steps;

[0067] S1. Purchasing fresh and complete Scrophulariae scrophulariae, the length of each Scrophulariae scrophulariae is not less than 15 cm;

[0068] S2, shaking off excess soil and impurities on the Scrophulariaceae;

[0069] S3, grading Scrophulariae according to the size of the diameter of each scrophulariaceae, and then cleaning the graded Scrophulariaceae;

[0070] S4, putting the graded Scrophulariaceae into an oven for pre-drying treatment, the pre-drying treatment is divided into the following six stages;

[0071] The first stage is 11 hours; the temperature in the oven is 38 degrees Celsius and the relative humidity is 28;

[0072] The second stage is 11 hours; the temperature in the oven is 43 degrees Celsius and the relative humidity is 30;

[0073] The third stage is 16 hours; the temperature in the oven is 47 degrees Celsius and the relative humidity is 32;

[0074] The...

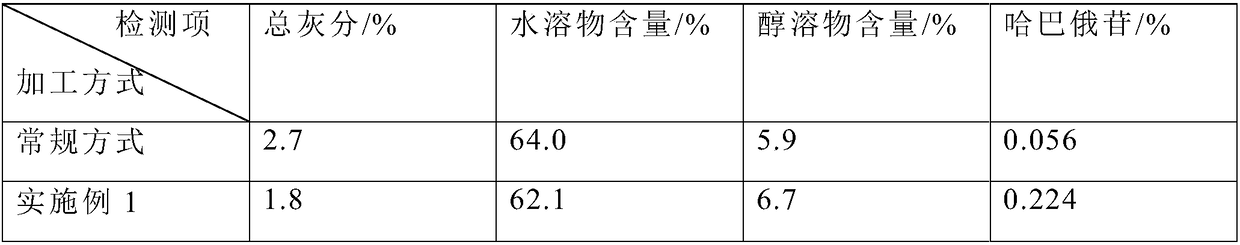

Embodiment 3

[0099] The origin processing technology of Scrophulariaceae includes the following steps;

[0100] S1. Purchasing fresh and complete Scrophulariae scrophulariae, the length of each Scrophulariae scrophulariae is not less than 15 cm;

[0101] S2, shaking off excess soil and impurities on the Scrophulariaceae;

[0102] S3, grading Scrophulariae according to the size of the diameter of each scrophulariaceae, and then cleaning the graded Scrophulariaceae;

[0103] S4, putting the graded Scrophulariaceae into an oven for pre-drying treatment, the pre-drying treatment is divided into the following six stages;

[0104] The first stage is 10 hours; the temperature in the oven is 36 degrees Celsius and the relative humidity is 27;

[0105] The second stage is 10 hours; the temperature in the oven is 40 degrees Celsius and the relative humidity is 29;

[0106] The third stage is 15 hours; the temperature in the oven is 44 degrees Celsius and the relative humidity is 31;

[0107] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com