Automobile tire retaining device

A technology for automobiles and blocking plates, which is applied to motor vehicles, goods transport vehicles, vehicles used for freight transportation, etc., can solve the problems of high processing cost, many process steps, and troublesome manufacturing, and achieves improved structural strength, high structural strength, Create convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

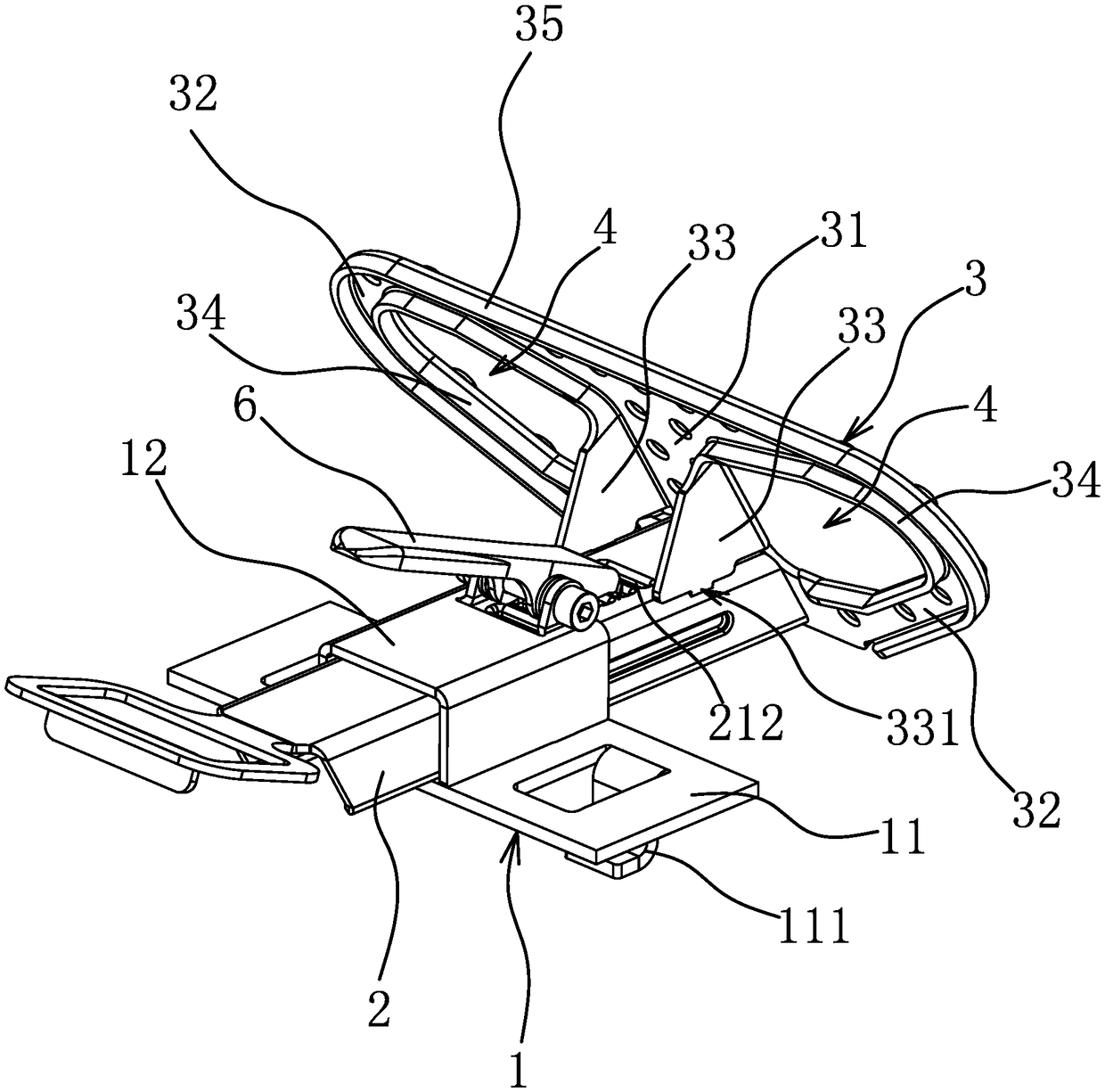

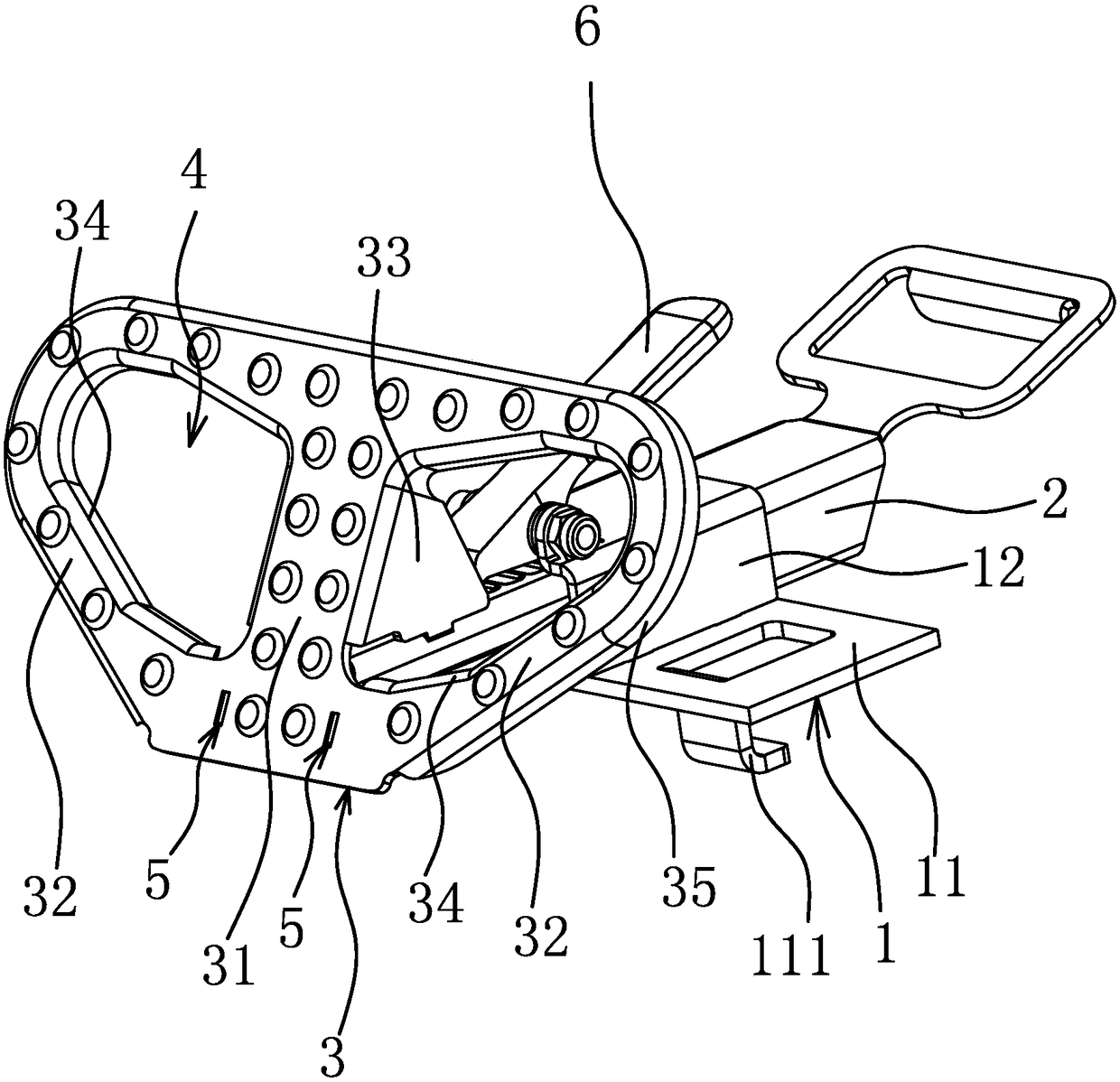

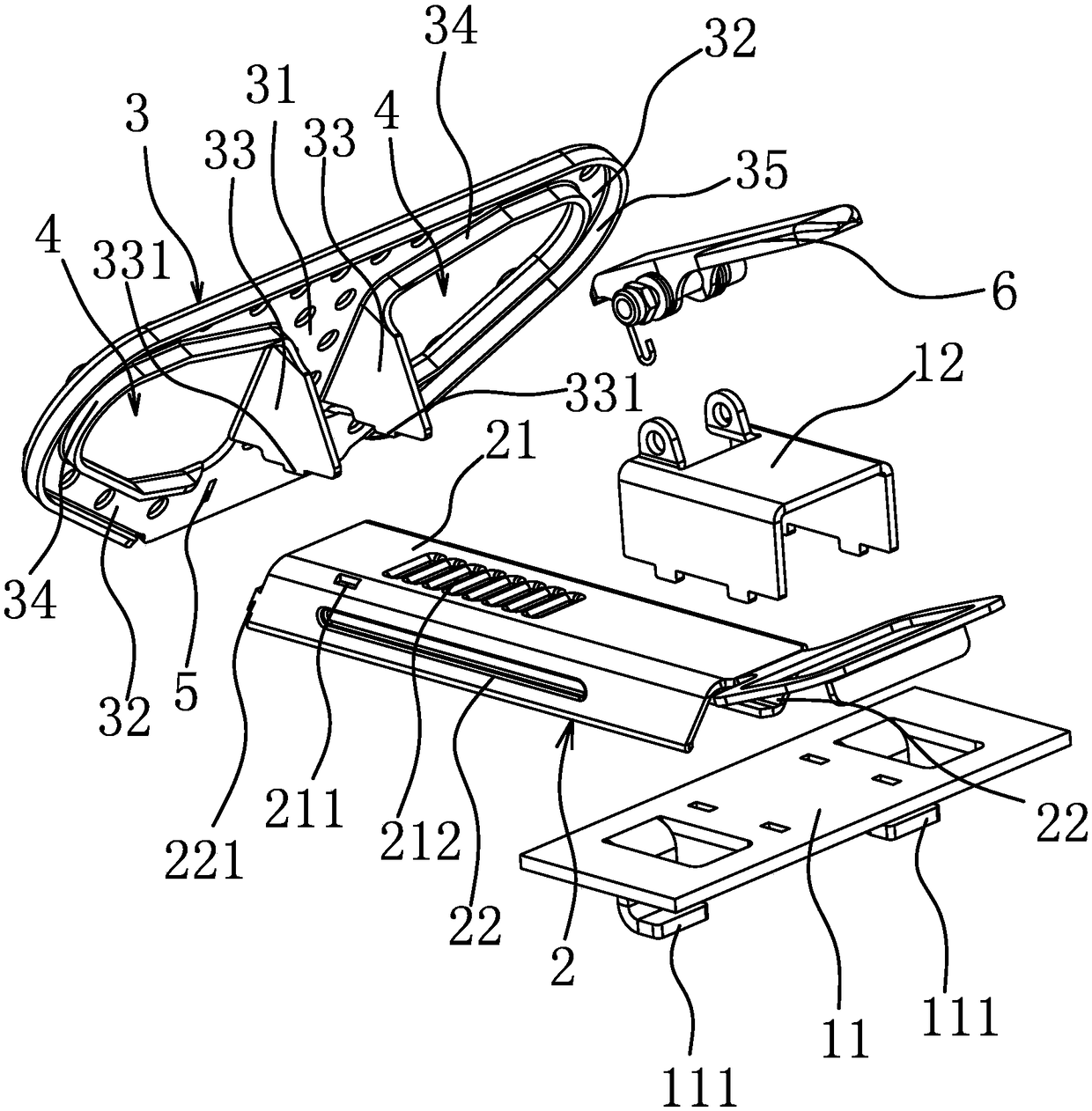

[0026] Such as figure 1 with figure 2 As shown, the automobile tire stopper includes a fixed seat 1 and an adjustment member 2 connected to the fixed seat 1. The front end of the adjustment member 2 is fixedly connected with a blocking plate 3 for abutting against the vehicle wheel, and the fixed seat 1 is used for connecting And fixed on the truck compartment floor.

[0027] Specifically, such as image 3 As shown, the adjusting part 2 is in the shape of a strip, and its cross section is U-shaped. It leans against and is fixedly connected to the bottom of the back of the blocking plate 3 .

[0028]The fixing seat 1 includes a base plate 11 and a seat body 12 plugged on the floor. Two L-shaped connecting hooks 111 for positioning with the compartment floor of the truck are punched and formed on the base plate 11 . The seat body 12 is in the shape of a U-shaped plate, and the seat body 12 is fixed by welding after being inserted on the bottom plate 11, and a guide hole for...

Embodiment 2

[0033] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference is that the plug-in positioning structure can be easily replaced by the following: a U that matches the cross-sectional shape of the adjustment member 2 is provided at the bottom of the blocking plate 3. The front end of the adjustment part 2 can be inserted into the U-shaped insertion groove as a whole, so that the mutual positioning between the blocking plate 3 and the adjustment part 2 is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com