Aircraft hydraulic brake system with independent anti-skid function

A technology for aircraft hydraulic and braking systems, applied in aircraft braking arrangements, vehicle components, brakes, etc., can solve problems such as difficult troubleshooting, low reliability, and complex design and configuration, and improve runway utilization and equipment Utilization rate, high reliability, reasonable structure and feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

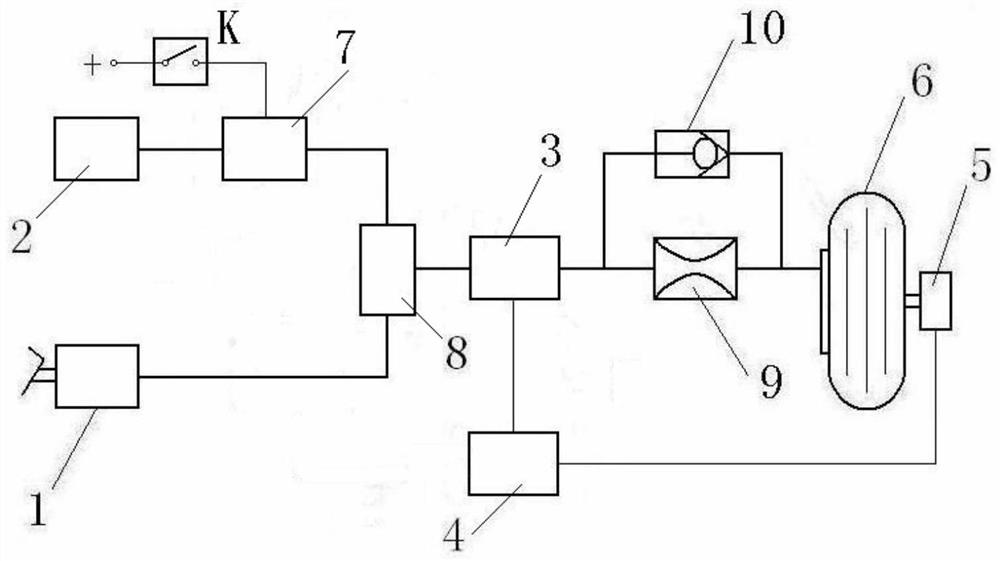

[0023] In this embodiment, the automatic braking is set to one level. The automatic brake anti-skid valve adopts an electro-hydraulic servo valve 3 as a common anti-skid valve.

[0024] An aircraft hydraulic braking system with automatic braking capability, the system comprises: hydraulic braking valve 1, electro-hydraulic servo valve 3, pressure reducing valve 2, hydraulic-electric valve 7, first switching valve 8, automatic braking switch K, throttle 9, one-way valve 10, speed sensor 5 and anti-skid control box 4.

[0025] Among them, hydraulic brake valve 1, electro-hydraulic servo valve 3, speed sensor 5 and anti-skid control box 4 constitute a normal braking system. The normal braking system is set according to the prior art.

[0026] Automatic brake switch K, pressure reducing valve 2, hydraulic valve 7, first switching valve 8, throttle 9, one-way valve 10, speed sensor 5, and anti-skid control box 4 form an automatic braking system. The speed sensor 5, the anti-skid...

Embodiment 2

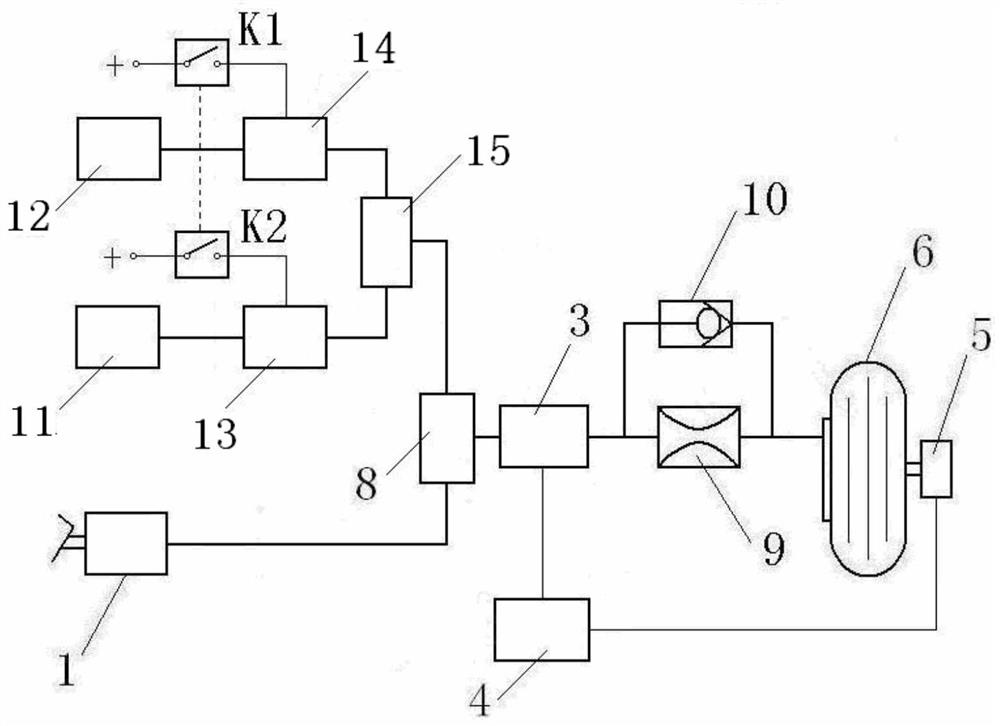

[0036] The difference between this embodiment and Embodiment 1 is that the automatic braking system is two-level. Two-stage automatic braking is set, and the pressure reduction pressure of one pressure reducing valve is lower than that of the other pressure reducing valve.

[0037] This embodiment is an aircraft hydraulic braking system with automatic braking capability, including a hydraulic braking valve 1, an electro-hydraulic servo valve 3, a first pressure reducing valve 11, a second pressure reducing valve 12, a first hydraulic-electric valve 13, a first pressure reducing valve 13, Two hydraulic valve 14 , first switching valve 8 , second switching valve 15 , first automatic brake switch K1 , second automatic brake switch K2 , throttle 9 , one-way valve 10 , speed sensor 5 and anti-skid control box 4 .

[0038] Among them, hydraulic brake valve 1, electro-hydraulic servo valve 3, speed sensor 5 and anti-skid control box 4 constitute a normal braking system. The first a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com