Automatic discharging mechanism

A blanking mechanism and blanking device technology, applied in the field of machinery, can solve the problems of uneven material mixing, poor quality, low efficiency, etc., and achieve the effect of improving efficiency and quality, avoiding noise annoyance and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

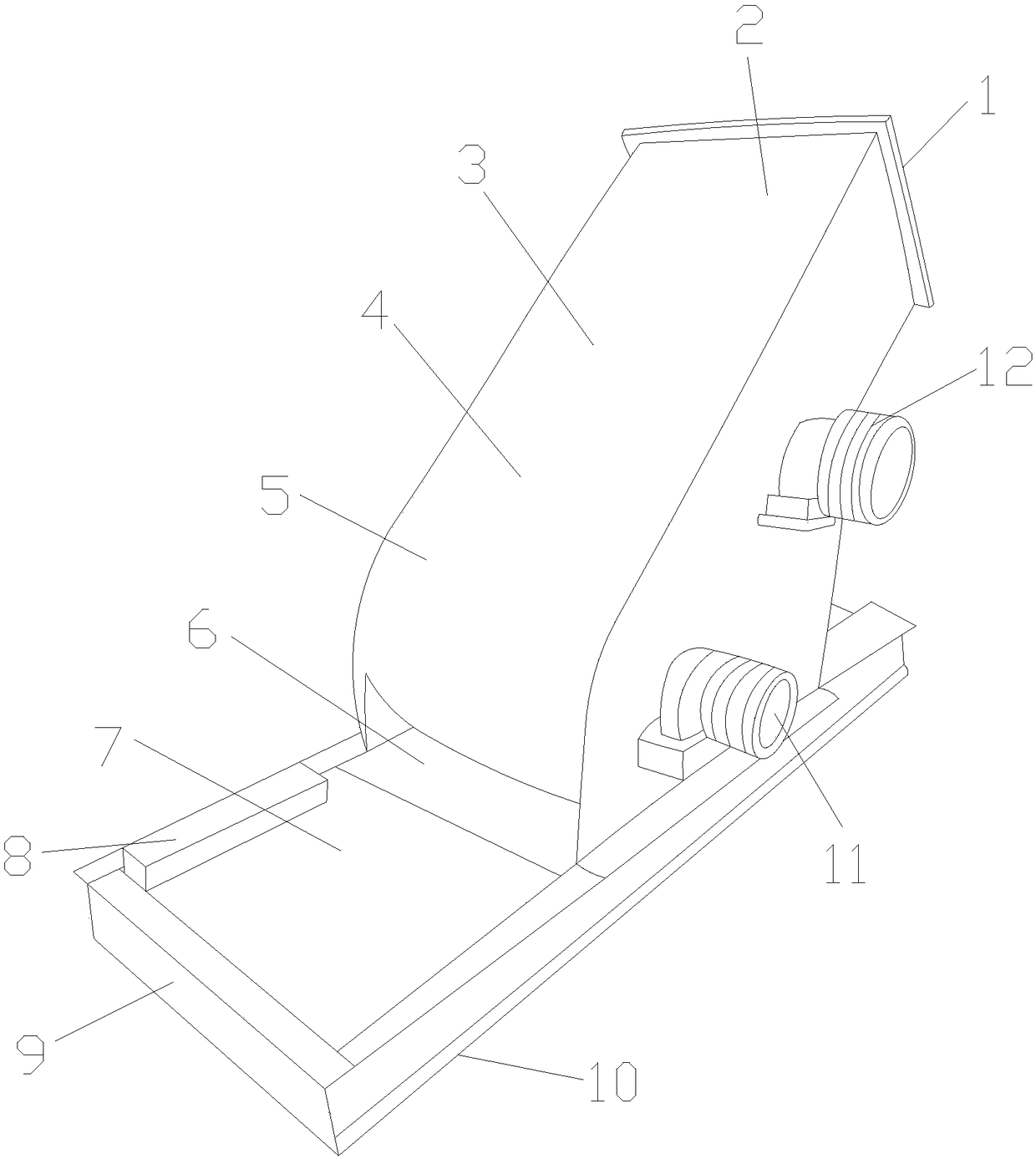

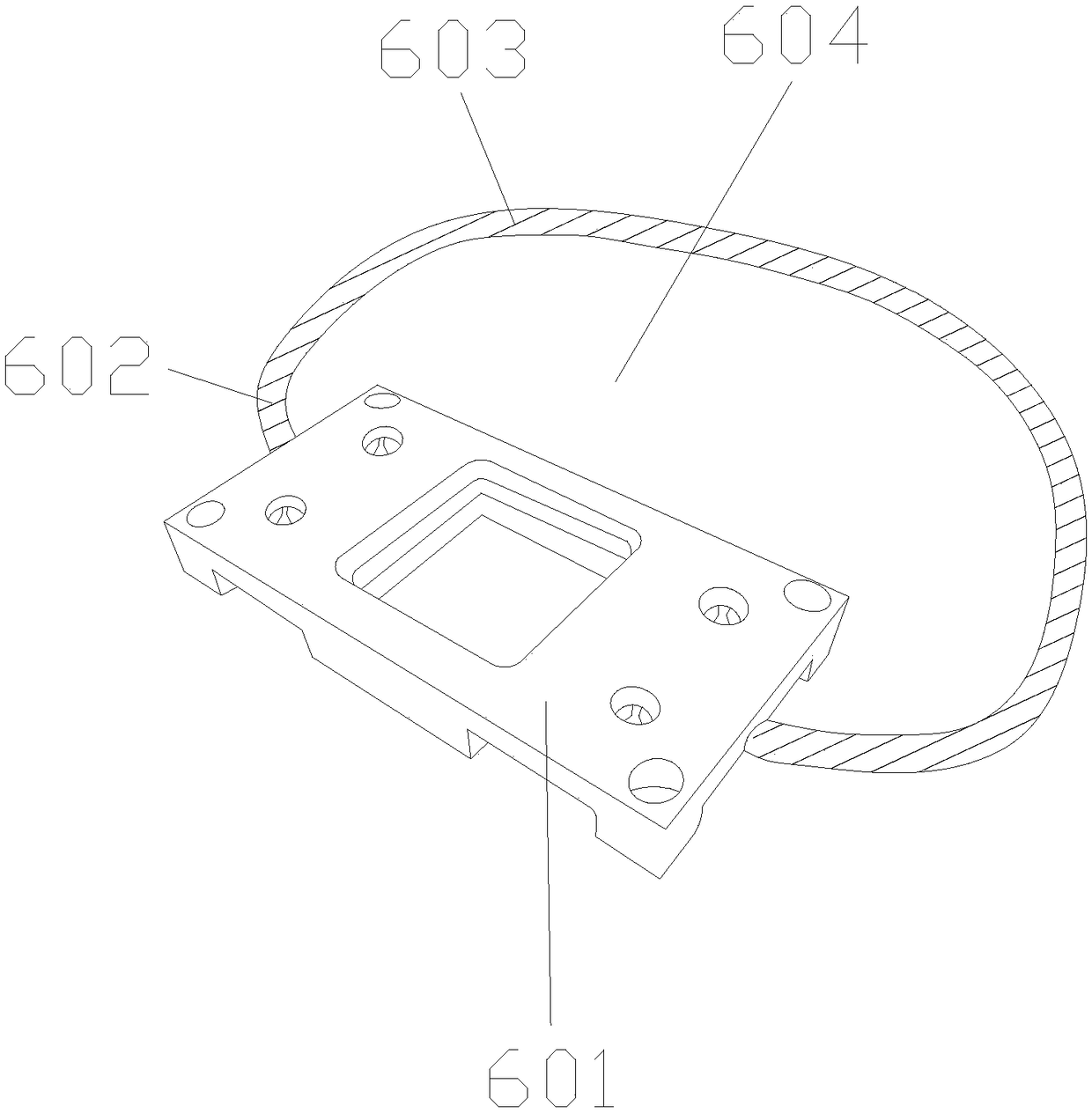

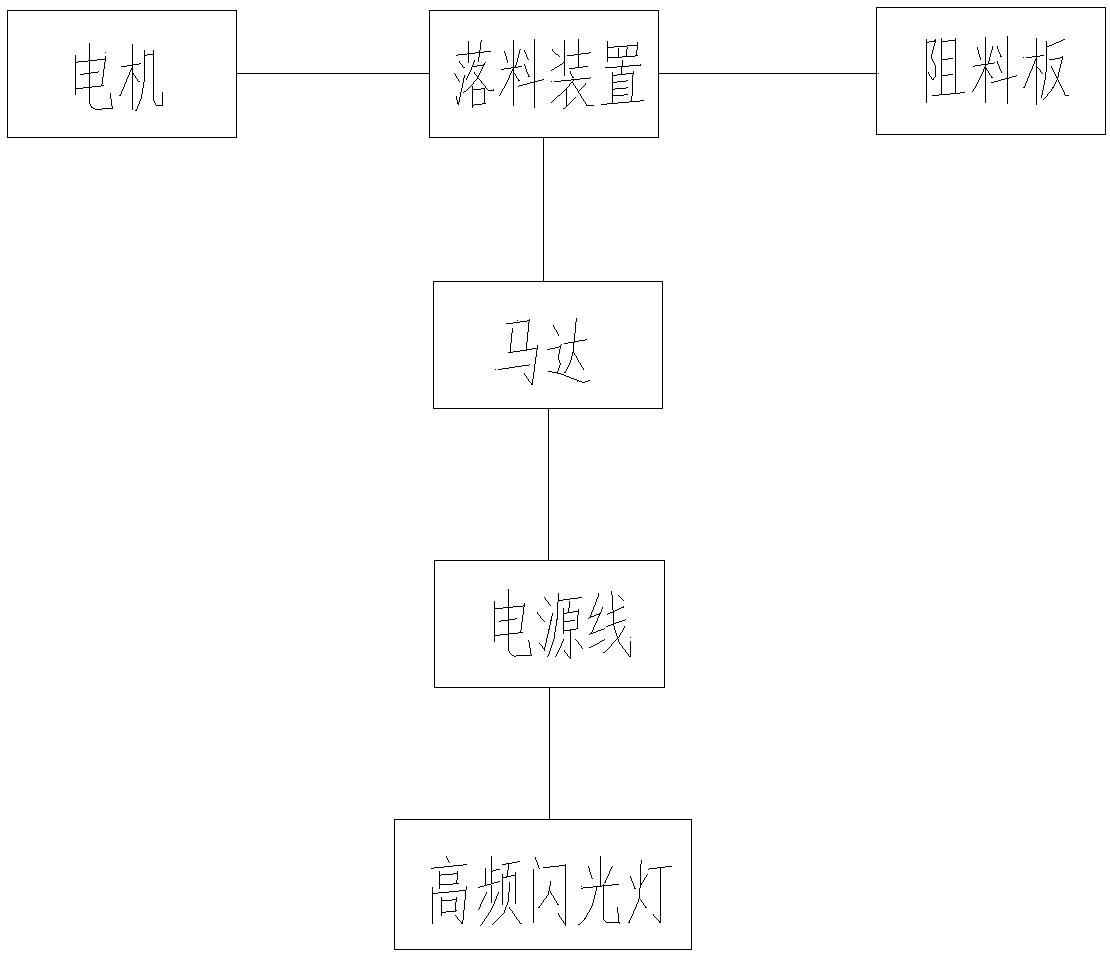

[0018] see Figure 1-Figure 2 , the present invention provides a technical solution: an automatic blanking mechanism, the structure of which includes a feed port 1, a hopper 2, a frame 3, a delivery pipe 4, a storage tank 5, a blanking device 6, a conveyor belt 7, a processing rod 8. The discharge port 9, the machine tool 10, the exhaust port 11, the motor 12, the material in the feed port 1 slides into the hopper 2, and the delivery pipe 4 transports the material to the storage barrel 5, and the storage barrel 5 is provided with a blanking device 6, the blanking device 6 is composed of a motor 601, a power cord 602, a high-frequency flash lamp 603, and a material blocking plate 604, the motor 601 is connected to the power line 602, and the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com