Shell coating for corn screening machine

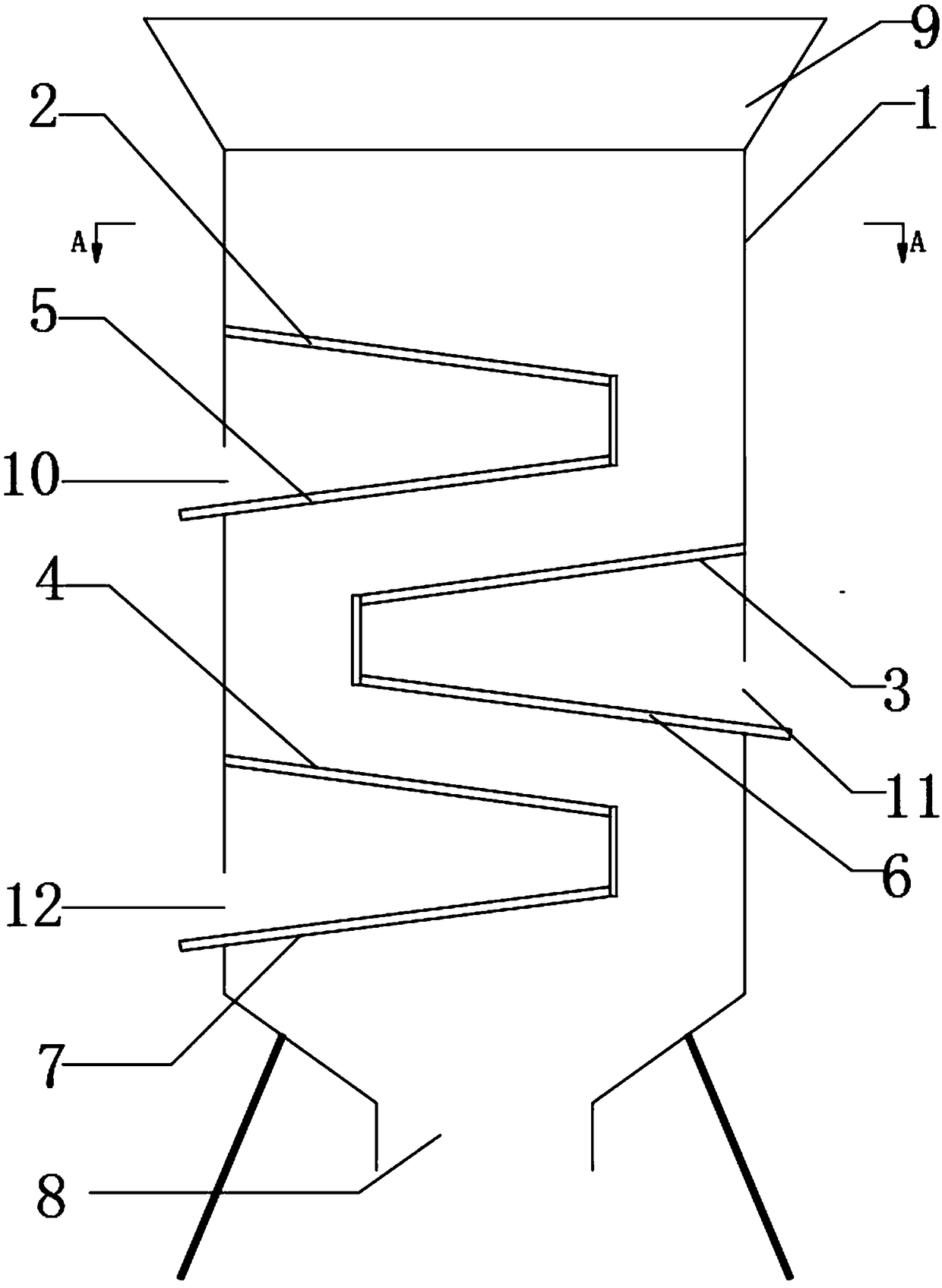

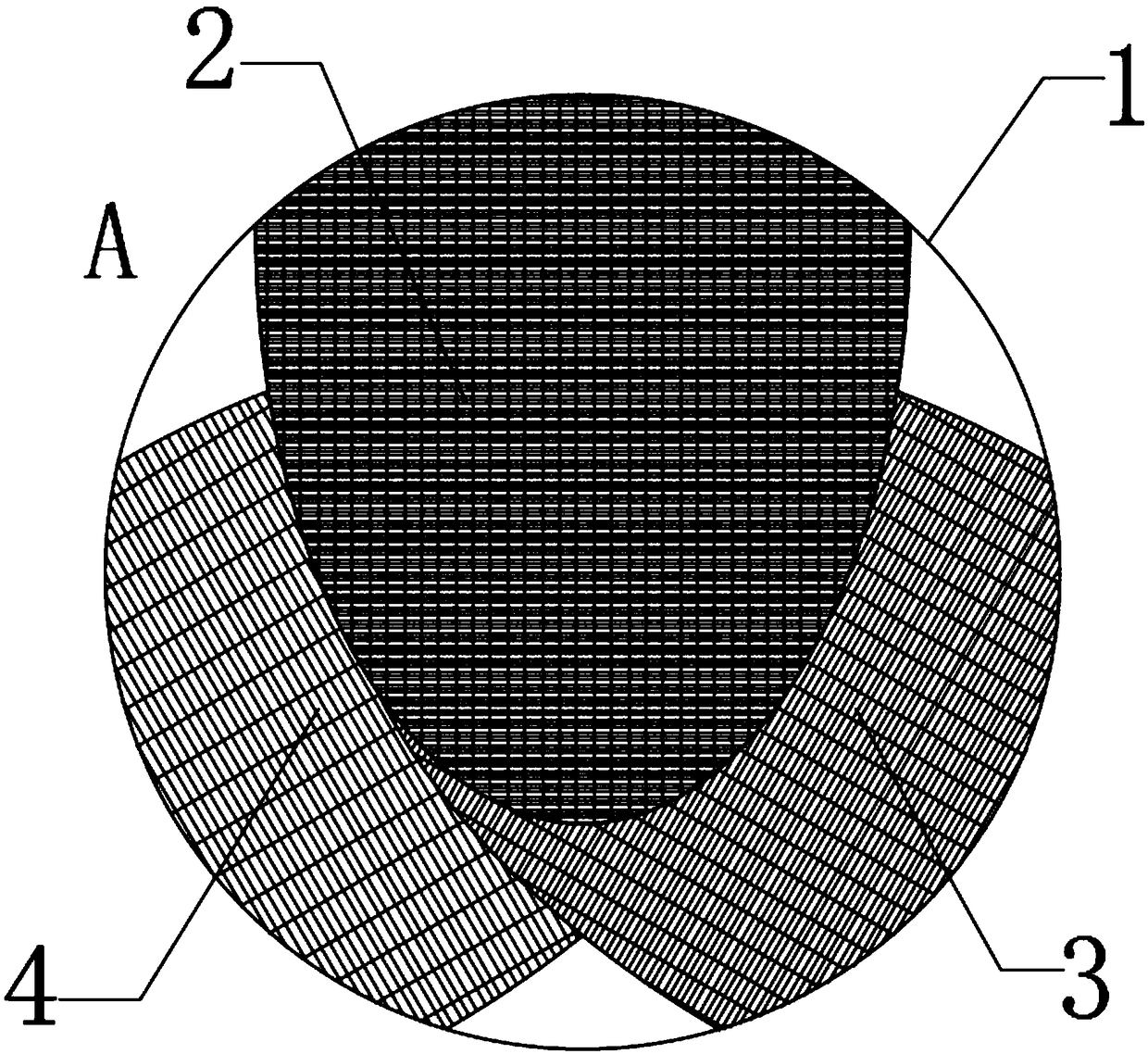

A screening machine and casing technology, which can be used in coatings, conductive coatings, epoxy resin coatings, etc., can solve the problems of easy accumulation of dust and corn odor in the casing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

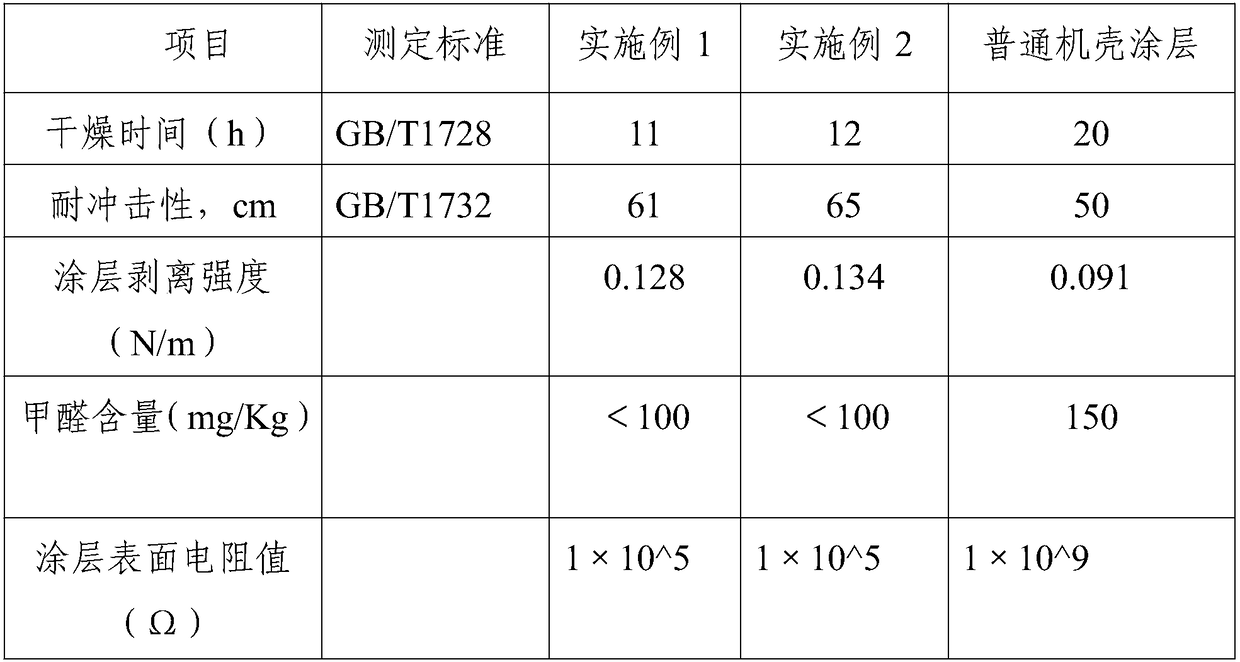

Embodiment 1

[0019] A casing coating for a corn sieving machine, preferably, the casing coating includes the following components: 35-43 parts of epoxy acrylic resin, 8-12 parts of natural rubber latex, 6-10 parts of oxidized polypropylene ester , 11-14 parts of butanediol, 4-7 parts of modified graphene, 15-20 parts of melamine, 6-12 parts of antistatic agent, 1-3 parts of antistatic additive, 3-8 parts of nano metal compound, antistatic 0.1-0.5 parts of oxygen agent, 0.3-0.8 parts of stabilizer, 3-5 parts of dispersant, 16-22 parts of plasticizer, 2-4 parts of leveling agent, 3-5 parts of film-forming aid.

[0020] Preferably, the antistatic agent is one or a mixture of alkanol ammonium salts, mixed valence tin oxides, and mixed valence molybdenum oxides.

Embodiment 2

[0022] A casing coating for a corn sieving machine, preferably, the casing coating includes the following components: 35-43 parts of epoxy acrylic resin, 8-12 parts of natural rubber latex, 6-10 parts of oxidized polypropylene ester , 11-14 parts of butanediol, 4-7 parts of modified graphene, 15-20 parts of melamine, 6-12 parts of antistatic agent, 1-3 parts of antistatic additive, 3-8 parts of nano metal compound, antistatic 0.1-0.5 parts of oxygen agent, 0.3-0.8 parts of stabilizer, 3-5 parts of dispersant, 16-22 parts of plasticizer, 2-4 parts of leveling agent, 3-5 parts of film-forming aid.

[0023] Preferably, the antistatic agent is one or a mixture of alkanol ammonium salts, mixed valence tin oxides, and mixed valence molybdenum oxides.

[0024] Preferably, the preparation method of the casing coating comprises the following steps:

[0025] S1. Put epoxy acrylic resin, natural rubber latex, oxidized polypropylene ester, butanediol, melamine, dispersant, and film-formi...

Embodiment 3

[0030] A casing coating for a corn sieving machine, preferably, the casing coating includes the following components: 35-43 parts of epoxy acrylic resin, 8-12 parts of natural rubber latex, 6-10 parts of oxidized polypropylene ester , 11-14 parts of butanediol, 4-7 parts of modified graphene, 15-20 parts of melamine, 6-12 parts of antistatic agent, 1-3 parts of antistatic additive, 3-8 parts of nano metal compound, antistatic 0.1-0.5 parts of oxygen agent, 0.3-0.8 parts of stabilizer, 3-5 parts of dispersant, 16-22 parts of plasticizer, 2-4 parts of leveling agent, 3-5 parts of film-forming aid.

[0031] Preferably, the antistatic agent is one or a mixture of alkanol ammonium salts, mixed valence tin oxides, and mixed valence molybdenum oxides.

[0032] Preferably, the preparation method of the casing coating comprises the following steps:

[0033] S1. Put epoxy acrylic resin, natural rubber latex, oxidized polypropylene ester, butanediol, melamine, dispersant, and film-formi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap