Tubular pile upper die and lifting system

A technology for pipe piles and hoisting devices, which is applied to molds, sheet pile walls, transportation and packaging, etc., can solve the problems of left and right shaking, manual hoisting, non-conformity, etc. The effect of preventing damage to the spreader

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

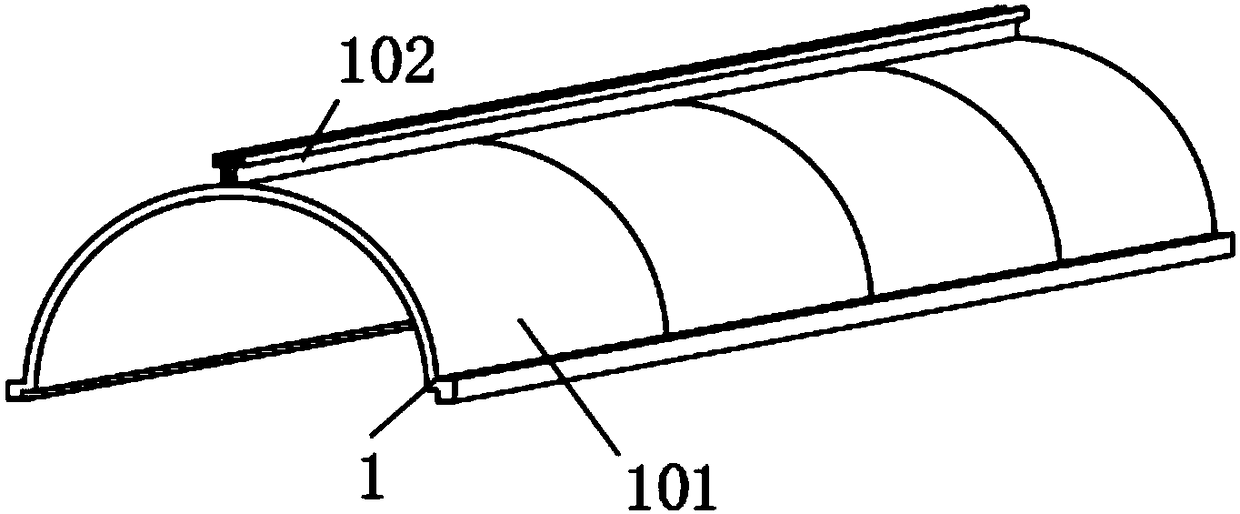

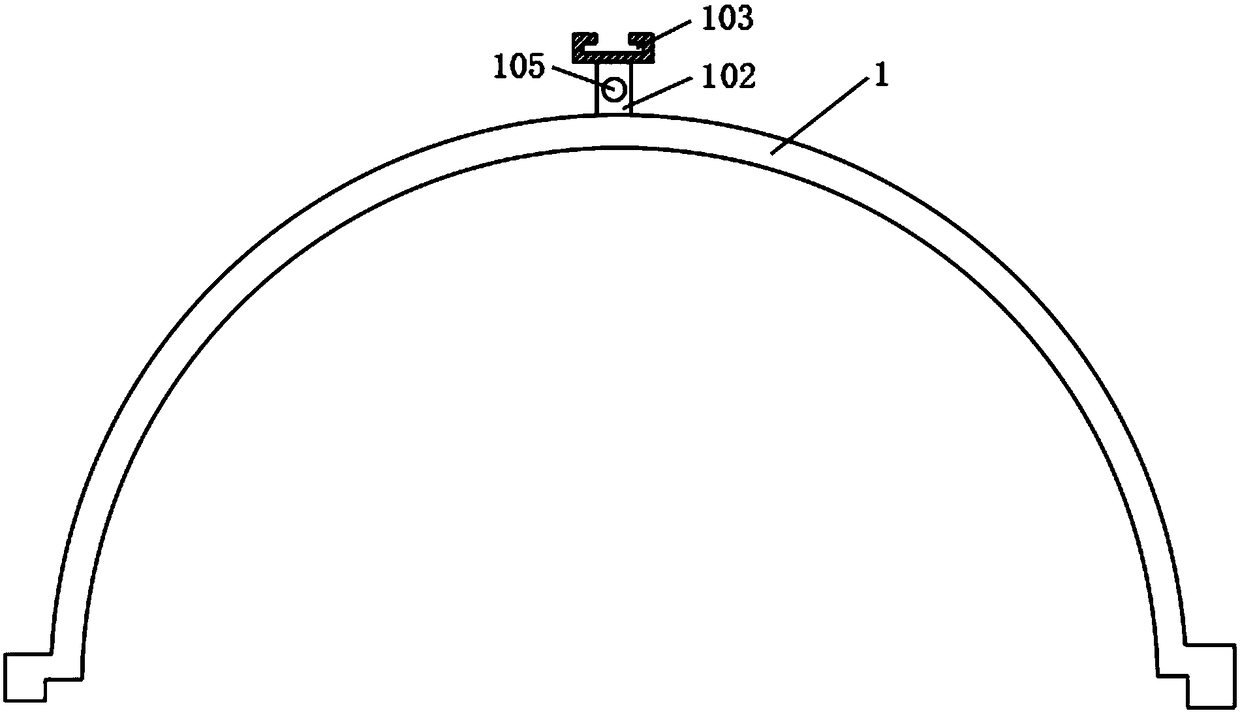

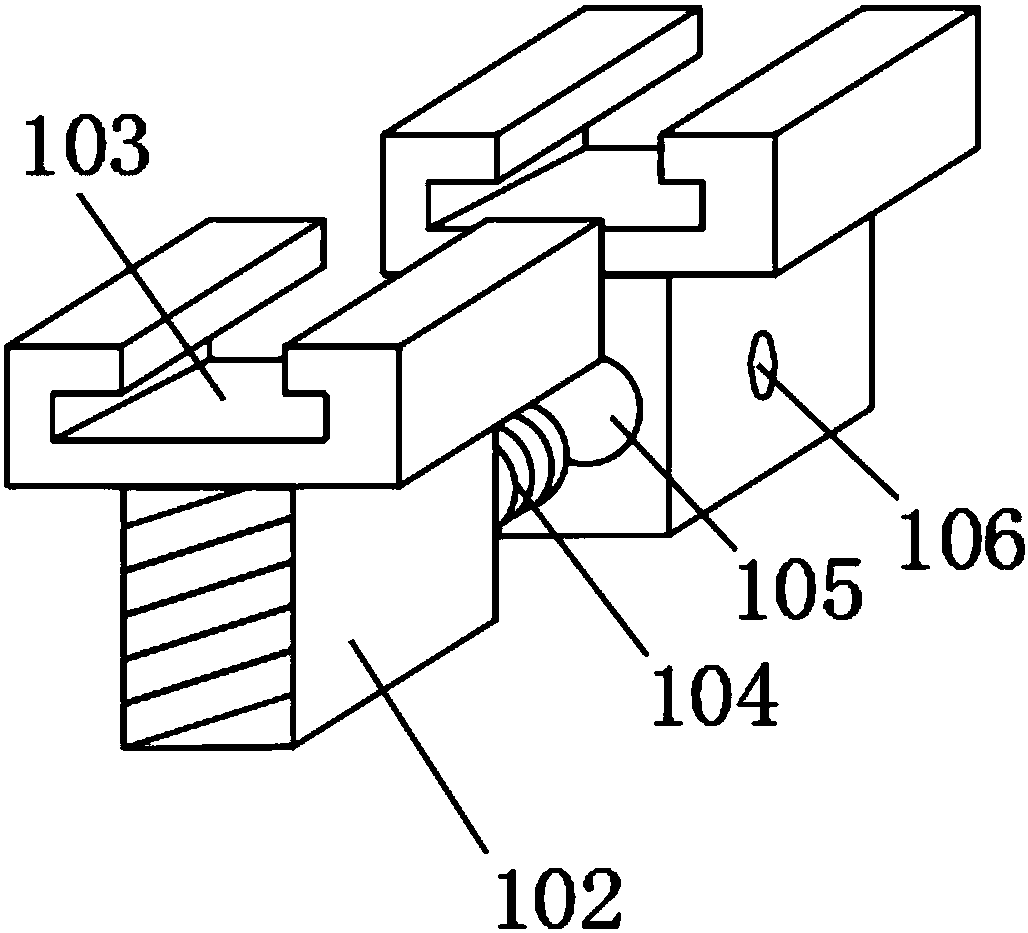

[0026] Example: such as Figure 1-8 As shown, the present invention provides a pipe pile upper mold and its hoisting system, including a pipe pile upper mold 1 and a hoisting device 2, and the pipe pile upper mold 1 includes an upper mold body 101, a T-shaped bracket 102, a connecting groove 103, a connecting convex Block 104, connecting groove 105, fixing through hole 106, buffer pad 107, limit block 108 and connecting bolt 109, the top of upper mold body 101 is provided with T-shaped support 102, and the top of T-shaped support 102 is provided with connecting groove 103 The middle part of one end of the T-shaped bracket 102 is provided with a connecting protrusion 104, the middle part of the other end of the T-shaped bracket 102 is provided with a connecting groove 105, and one side of the connecting groove 105 is provided with a fixing through hole 106, and the inside of the connecting groove 105 The bottom end of the connecting groove 105 is provided with a buffer pad 107,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com