Steel chimney installation overturn-preventing method and device

An anti-overturning and chimney technology, applied in the direction of building types, buildings, towers, etc., can solve problems such as the inability to set chimney restraint points and the danger of steel chimney overturning, so as to avoid personal safety problems and property losses, increase labor efficiency, and practicability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

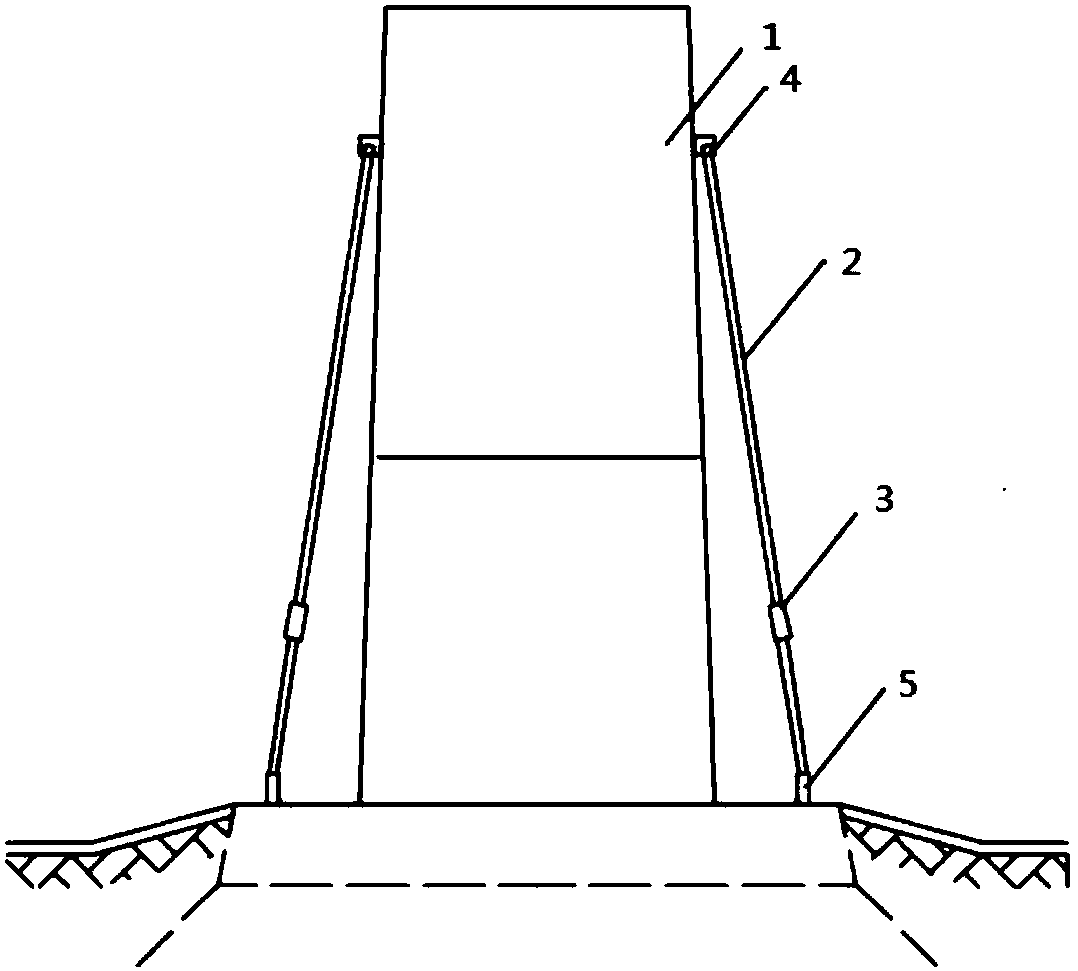

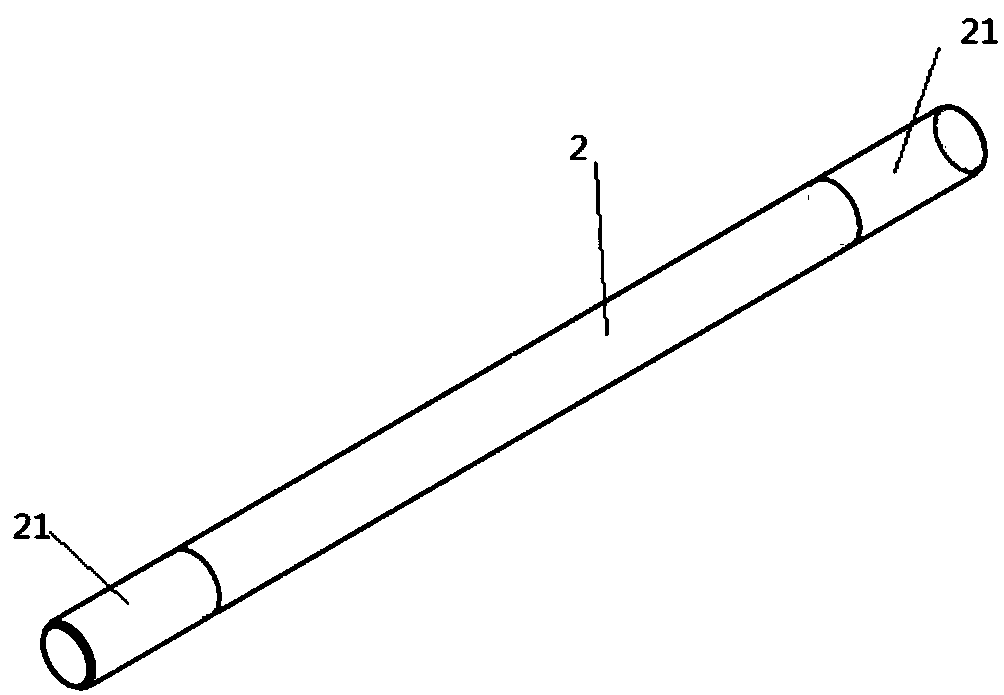

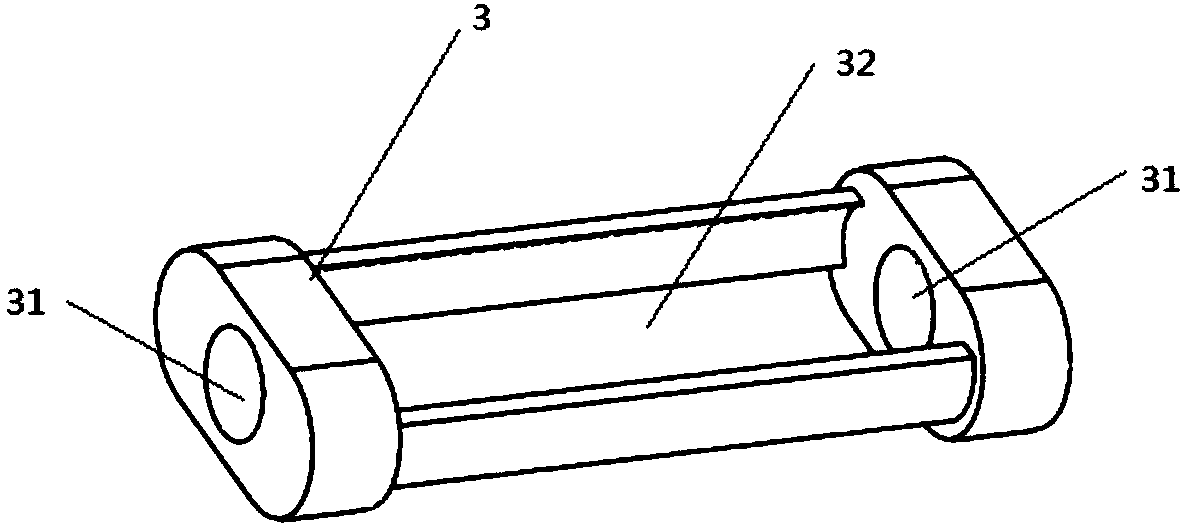

[0031] Such as figure 1 As shown, this example is a steel chimney installation anti-overturning device, including at least two pull rods 2, a connecting buckle 3, a first connecting mechanism 4 and a second connecting mechanism 5, and the two ends of the pull rod 2 are provided with external threads 21, and the pull rod 2 Different lengths are produced to meet the rising height of each chimney section. During the installation of the steel chimney, every time a section of the steel chimney is raised, a section of tie rod is correspondingly added, and nuts are used between every two tie rods 2 through the connecting buckle 3 To connect, the connecting buckle 3 includes circular through-holes 31 arranged at both ends of the connecting buckle 3 for penetration of the pull rod 2, and a rectangular through-hole 32 arranged in the middle for the nut to extend into the inside of the connecting buckle 3, The screw rod is fixed by the external thread provided on the nut and the pull rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com