Subway station structure built by pipe jacking process and construction method thereof

A technology of subway station and pipe jacking method, applied in infrastructure engineering, underwater structures, buildings, etc., can solve problems such as negative impact and short-term pain, achieve low air pollution and noise, avoid negative impact, and improve construction efficiency and construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

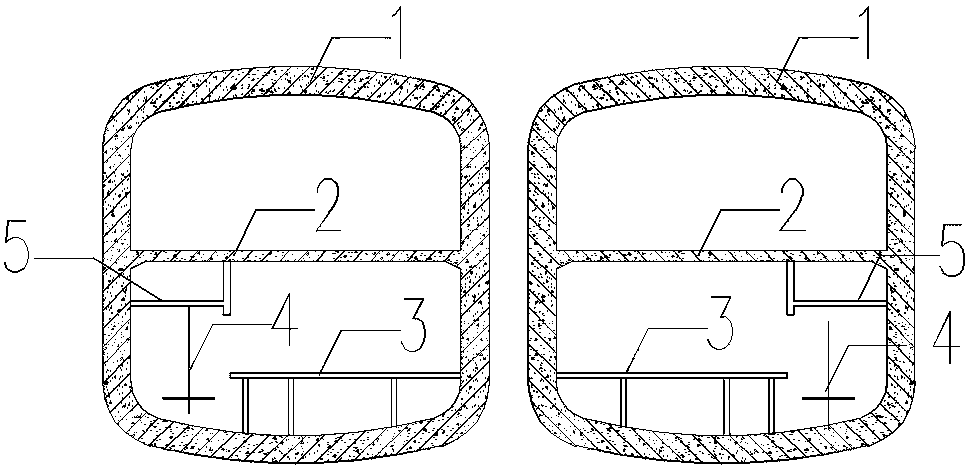

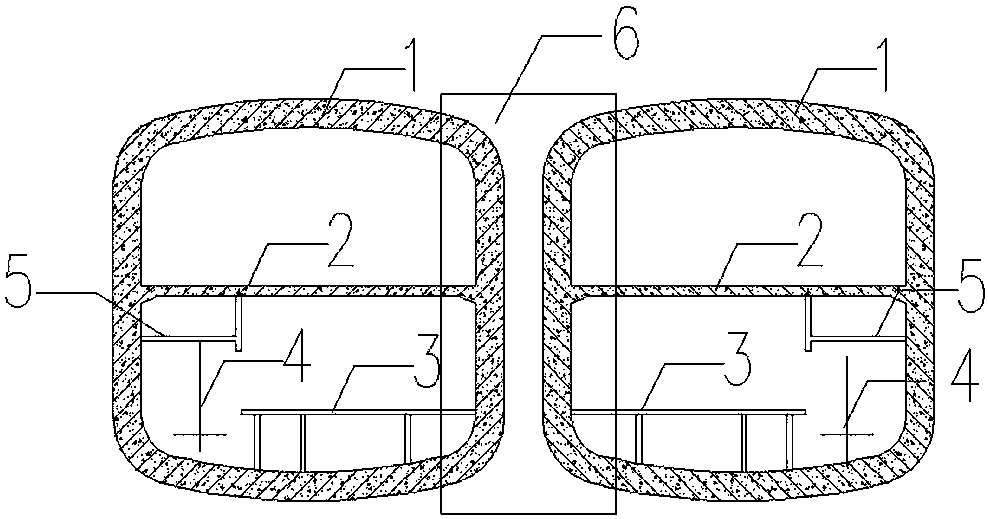

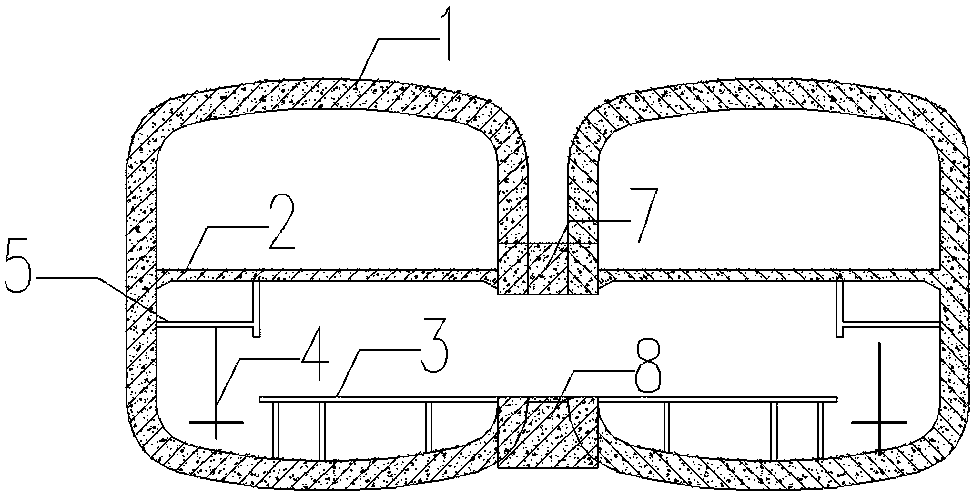

[0027] Such as Figure 1~4 Shown, provide a kind of subway station structure that adopts pipe jacking method to build, this subway station structure mainly comprises adopting pipe jacking machine to implement a plurality of mutually parallel pipe jacking tunnels 1, and the cross-sectional width of this pipe jacking tunnel after connection is the same as The height of the section matches the building width and building height of the subway station; inside each pipe jacking tunnel, there is a middle plate 2 on the subway station hall floor, and a rail top air duct 5 is arranged on the lower part of the middle plate on the subway station hall floor. The bottom of each pipe-jacking tunnel is also provided with a platform 3 and a driving track 4 respectively; adjacent pipe-jacking tunnels are connected through a channel top structure 7 and a channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com