A Partial Stroke Test Method of Coke Oven Collecting Pipe Gas Safety Release Water Seal Valve

A technology of partial stroke test and gas collecting pipe, applied in the direction of mechanical valve test, etc., can solve problems such as corrosion or blockage, and achieve the effect of low gas pressure, small opening degree of stroke test, and increasing valve opening degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

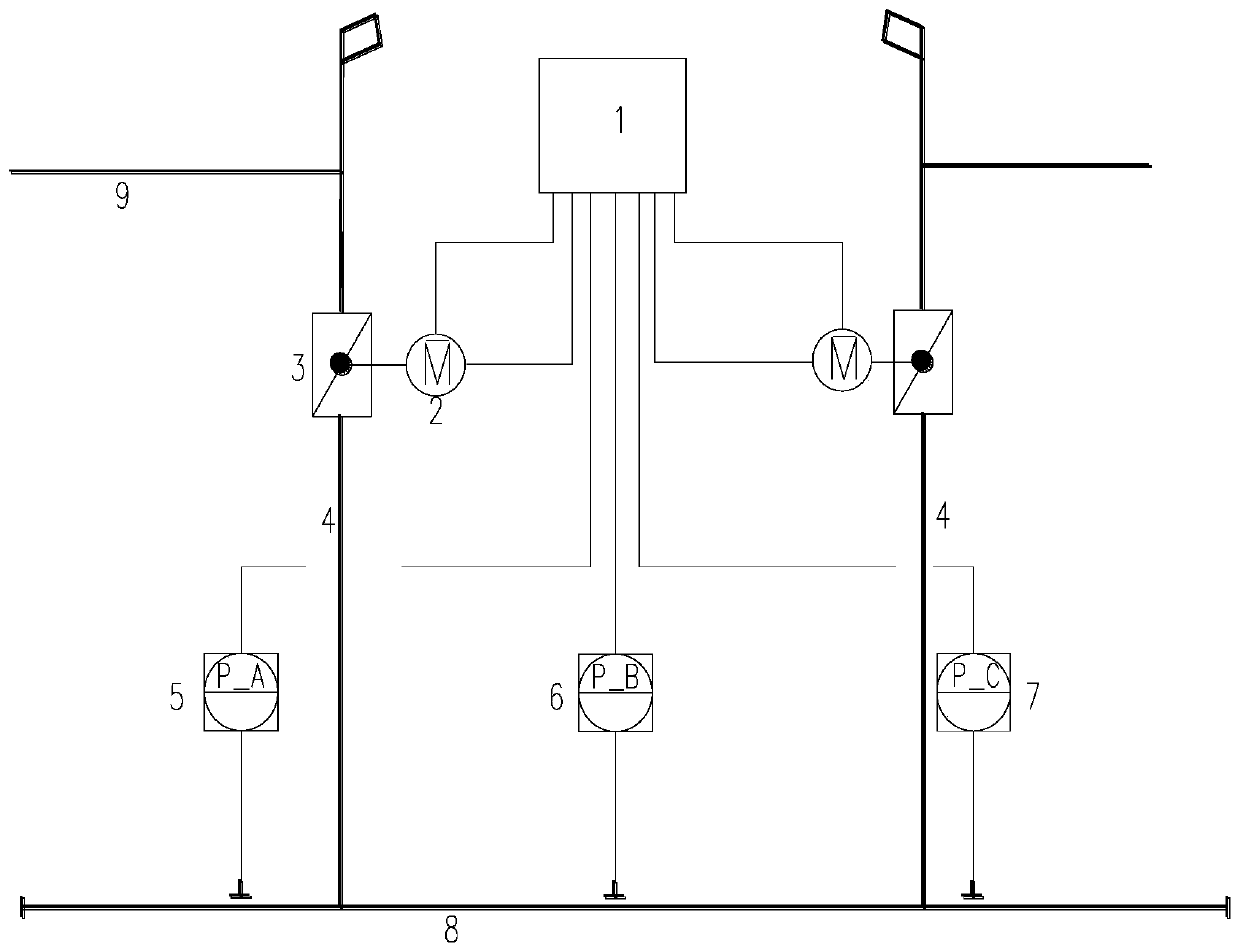

[0039] Such as figure 1 As shown, three pressure measuring points are set at the gas collecting pipe 8: pressure measuring point A5, pressure measuring point B6 and pressure measuring point C7, wherein the pressure measuring points 5 and 7 are arranged at the connection between the gas collecting pipe 8 and the outlet of the gas release pipe 4 nearby.

[0040] By taking the maximum value of the pressure at 3 points, it is ensured that the measured gas pressure is not lower than the 4 gas pressure of the gas release pipe. The minimum water seal height without gas leakage is calculated according to the measured gas pressure, and the maximum opening of the release water seal valve 3 is further obtained. The control system 1 controls the action of the electric actuator 2 to complete the stroke test of the release water seal valve 3 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com