LED lamp circuit board soldering point inspection device

A technology of LED lamps and inspection devices, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problem of inability to lubricate the first movable block and the first screw rod, inability to improve the illuminance of the detection area, and inability to detect Comprehensive scope and other issues, to achieve the effect of saving fixed time, increasing the detection effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

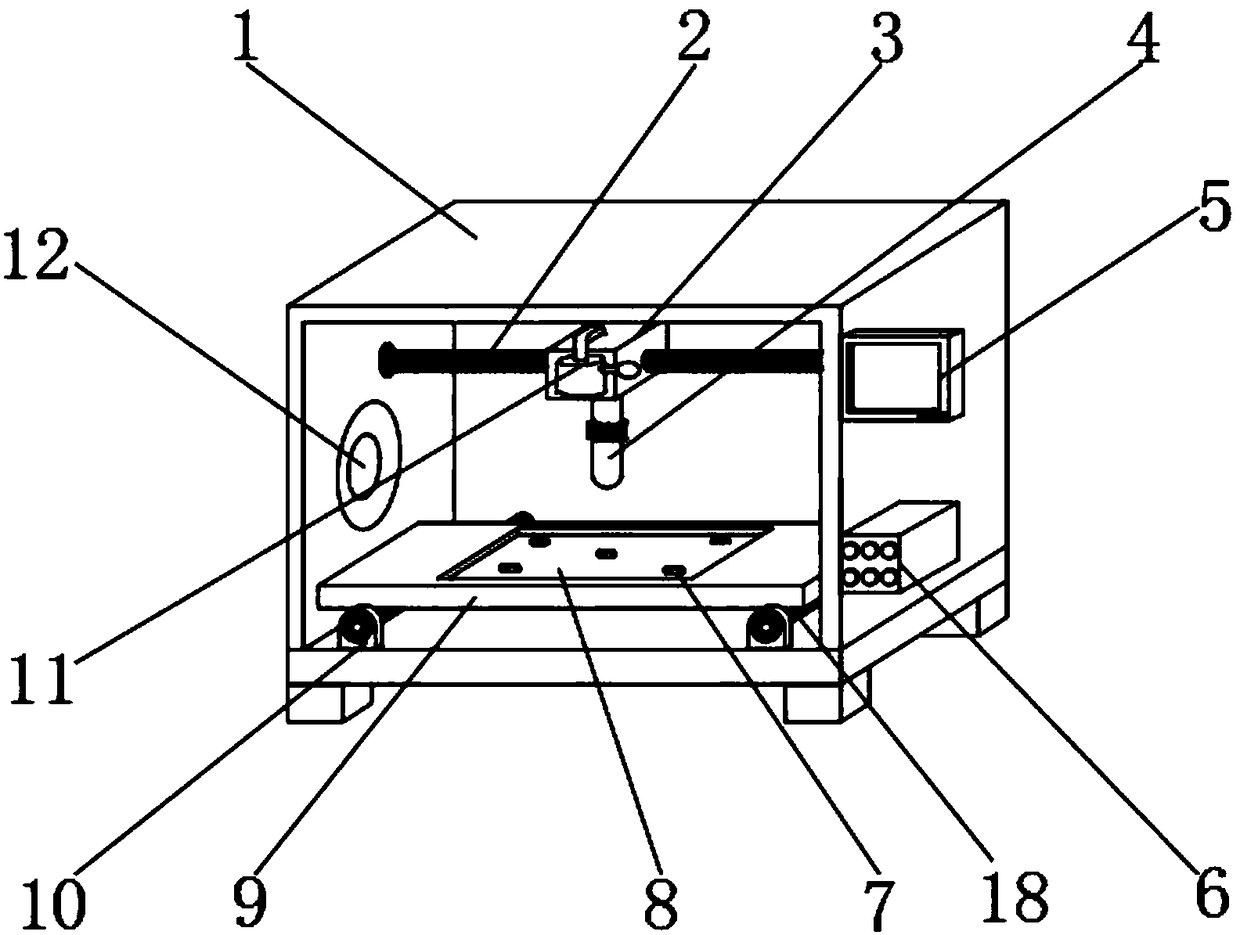

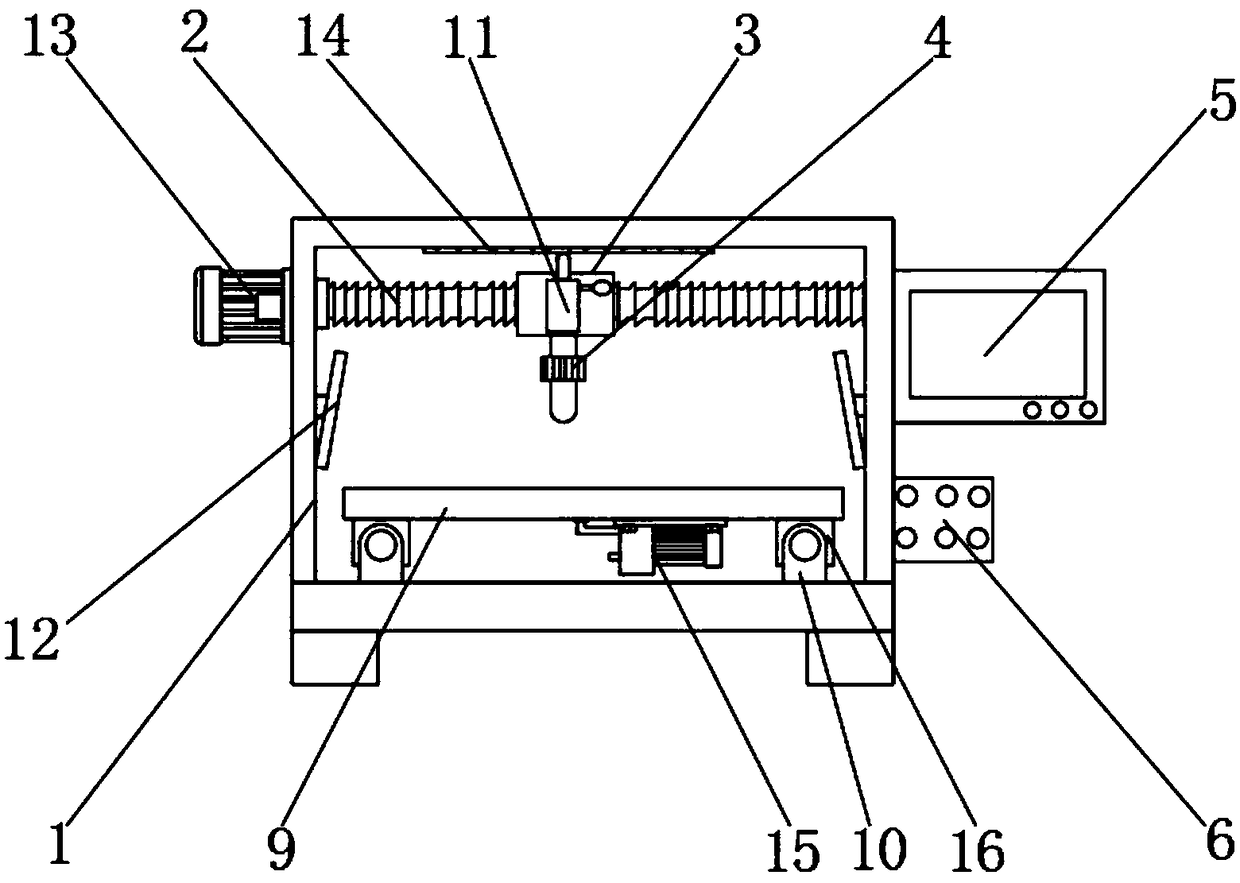

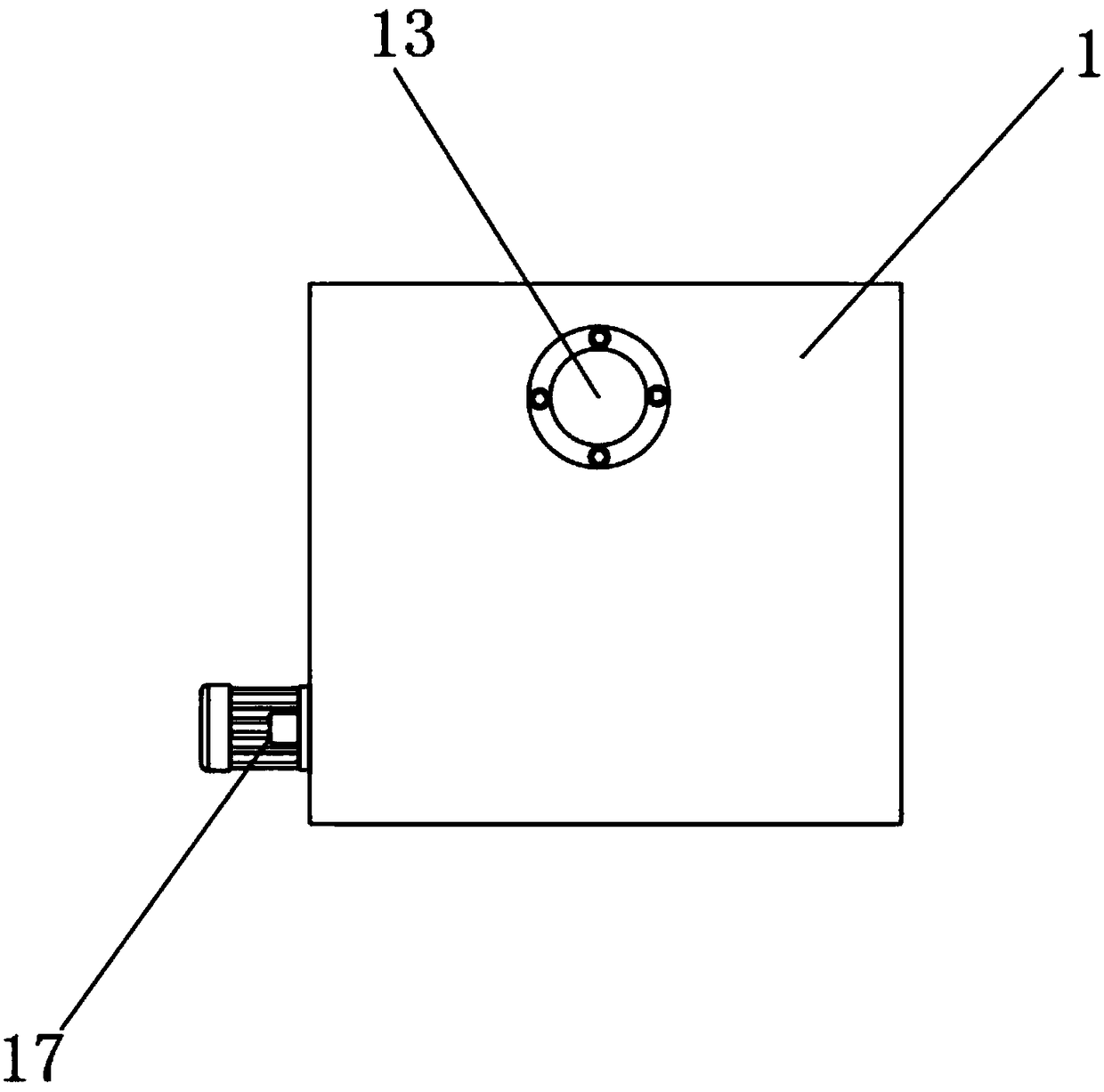

[0025] Example: refer to Figure 1-4 , the present invention provides a technical solution: a LED lamp circuit board solder joint inspection device, including a box 1, a first servo motor 13 is provided on one side of the box 1, and a display is provided on the other side of the box 1 5. A control switch 6 is provided on one side of the cabinet 1 close to the lower position of the display 5, and an LED light 14 is installed on the inner top of the cabinet 1, and a curved reflector 12 is provided on the inside of the cabinet 1, and the cabinet 1 The inner side of the box body 1 is provided with a first screw rod 2 corresponding to the position of the first servo motor 13, the inner bottom of the box body 1 is fixed with a connection block 10, and the rear side of the connection block 10 is provided at a position corresponding to the second servo motor 17. There is a second screw mandrel 18, a support plate 9 is arranged above the second screw mandrel 18, and a second movable bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com