Qualitative and quantitative method of antioxidant in polyolefin

A technology of antioxidants and polyolefins, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of unquantitative detection and analysis, no analysis methods, etc., and achieve the effects of improved solubility, improved sensitivity, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

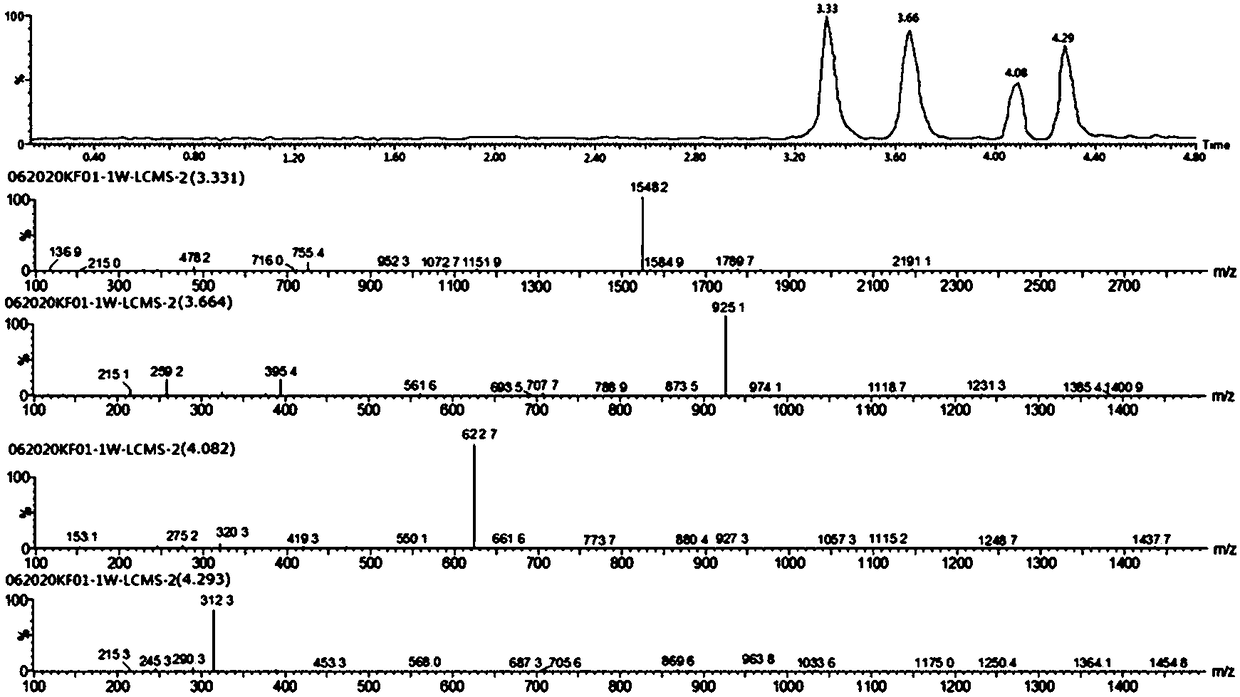

Image

Examples

Embodiment 1

[0077] Embodiment 1 provides the quantitative test method of antioxidant in polyolefin, comprises the steps:

[0078] Get 10g containing 0.5wt% antioxidant 1010, 0.5wt% antioxidant 168, 0.2wt% antioxidant 1076, and 0.3wt% BHT, isotactic polypropylene with a number average molecular weight of 150,000, press into thin sheets, and use Freeze with liquid nitrogen, crush with a grinder, add 150ml of chloroform, stir and dissolve at 70°C for 8 hours, then add 0.120g of anhydrous aluminum trichloride under stirring, adjust the temperature to 60°C, and add 0.075g of formazan dropwise at a uniform speed Aminosulfonyl chloride (CAS No. 10438-96-7, purchased from Wuhan Combeide Biotechnology Co., Ltd.), the dropwise addition was completed within 15 minutes and the temperature of the system was controlled at 60-65°C. React for 5 hours, then cool the reaction liquid to 25°C, filter, wash the filter residue with chloroform, combine the washing liquid with the filtered clear liquid, and add ...

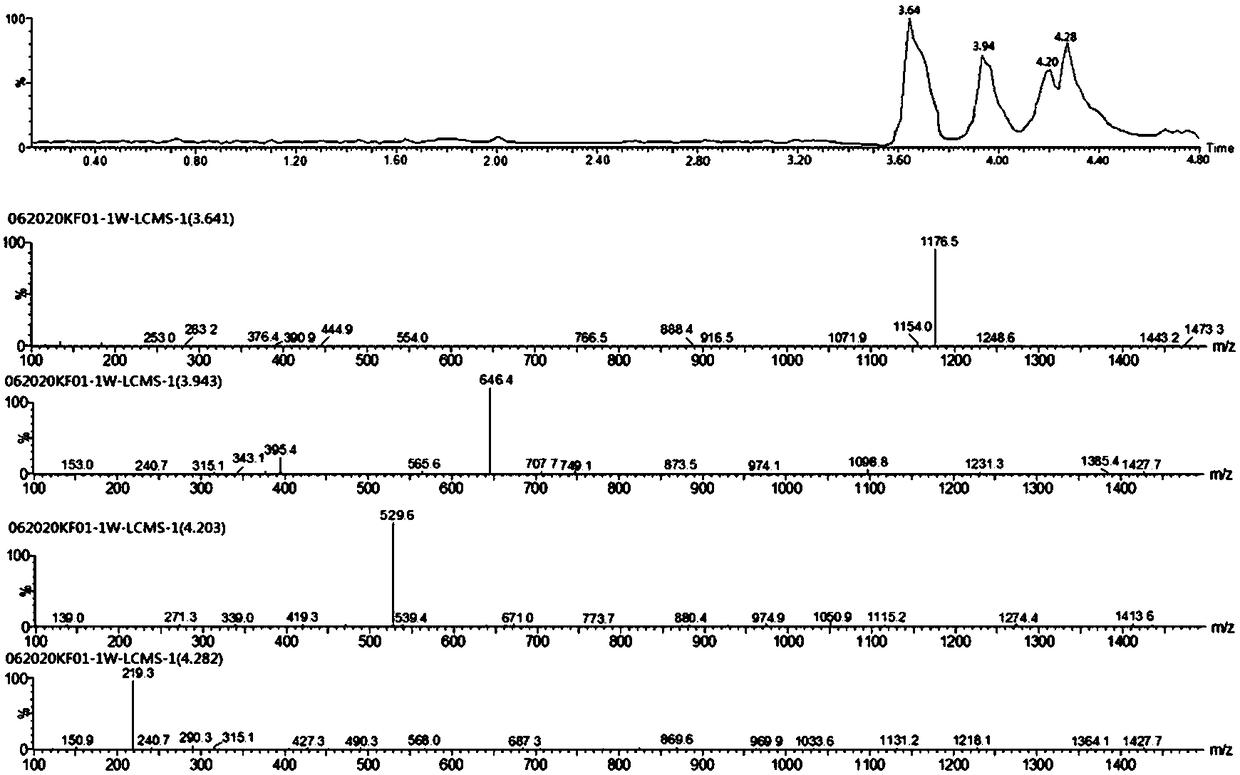

Embodiment 2

[0082] Embodiment 2 provides the quantitative testing method of antioxidant in polyolefin, comprises the steps:

[0083] Get 10g containing 0.5wt% antioxidant 1010, 0.5wt% antioxidant 168, 0.2wt% antioxidant 1076, and 0.3wt% BHT, isotactic polypropylene with a number average molecular weight of 150,000, press into thin sheets, and use Freeze with liquid nitrogen, crush with a pulverizer, add 150ml of chloroform, stir and dissolve at 70°C for 8 hours, then add 0.200g of anhydrous aluminum trichloride under stirring, adjust the temperature to 60°C, and add 0.075g of formazan dropwise at a uniform speed Aminosulfonyl chloride (CAS No. 10438-96-7, purchased from Wuhan Combeide Biotechnology Co., Ltd.), the dropwise addition was completed within 15 minutes and the temperature of the system was controlled at 60-65°C. React for 5 hours, then cool the reaction liquid to 25°C, filter, wash the filter residue with chloroform, combine the washing liquid with the filtered clear liquid, an...

Embodiment 3

[0087] Embodiment 3 provides the quantitative testing method of antioxidant in polyolefin, comprises the steps:

[0088]Get 10g containing 0.5wt% antioxidant 1010, 0.5wt% antioxidant 168, 0.2wt% antioxidant 1076, and 0.3wt% BHT, isotactic polypropylene with a number average molecular weight of 150,000, press into thin sheets, and use Freeze with liquid nitrogen, crush with a pulverizer, add 150ml of chloroform, stir and dissolve at 70°C for 8 hours, then add 0.170g of anhydrous aluminum chloride under stirring, adjust the temperature to 60°C, and add 0.043g of milk dropwise at a constant speed Acid anhydride, the dropwise addition is completed within 15 minutes and the temperature of the system is controlled at 60-65°C. After the dropwise addition, it is reacted at 65°C for 5 hours, and then the reaction solution is cooled to 25°C, filtered, and the filter residue is washed with chloroform. The washing liquid Combine with the filtered clear liquid, and add 70ml of glacial hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com