A kdtree-based spatial area generation method and system for sheet metal modeling

A sheet metal part and area technology, which is applied in the field of the spatial area generation method and system for sheet metal modeling, can solve the problem of low production efficiency, three-dimensional spatial structure of sheet metal part spatial area generation, long computation time, etc. problem, to achieve the effect of reliable use, reducing operation time, and solving long operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

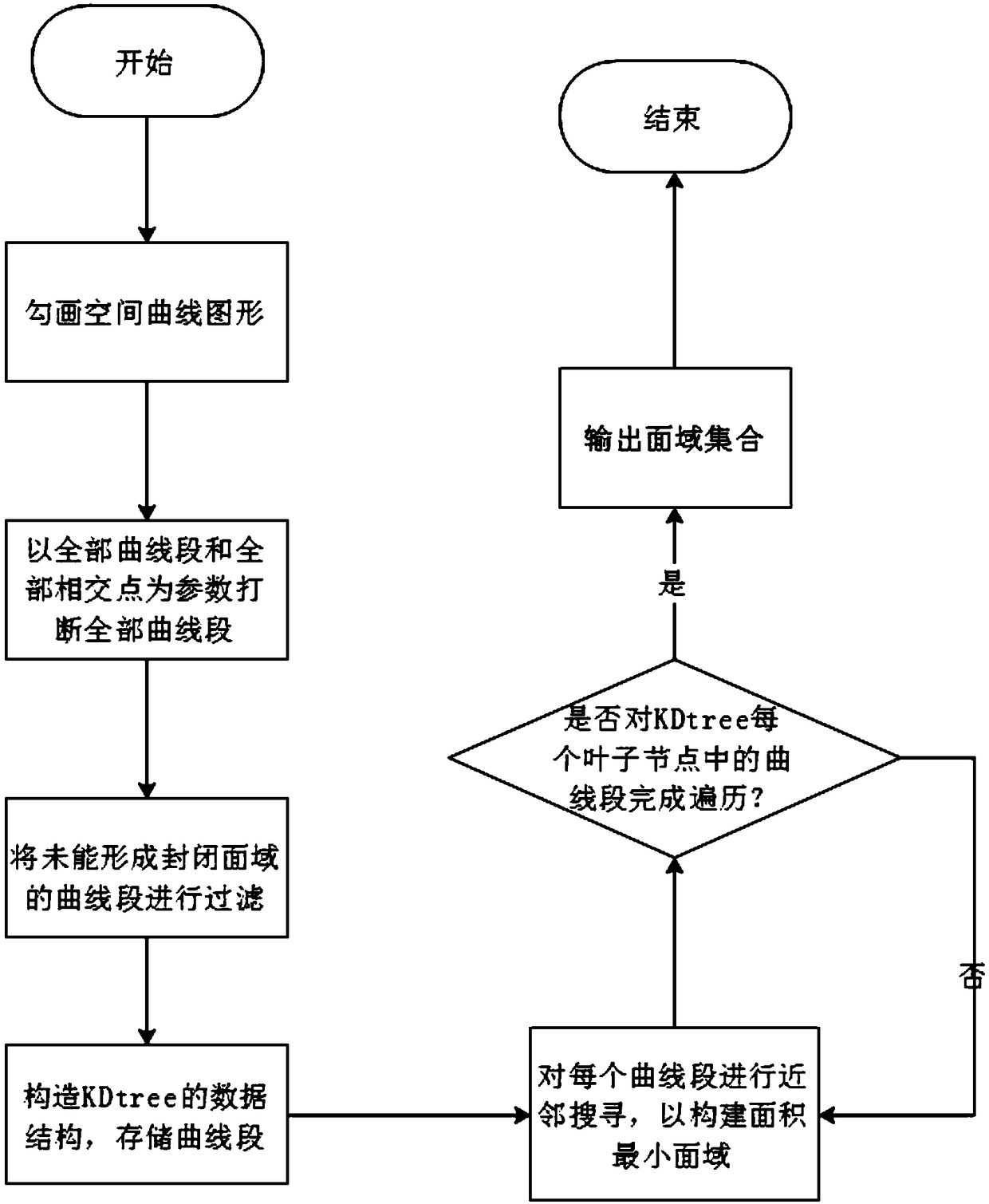

[0026] The KDtree-based spatial area generation method for sheet metal modeling in this embodiment uses CAD drawing software to perform step 1, and uses Rhino software to perform steps 2-5, but is not limited to the above software, in other embodiments In this process, you can also use other drafting software other than CAD to perform step 1, or use other 3D modeling software other than Rhino to perform steps 2-5. see figure 1 , the method of the present invention comprises the following steps:

[0027] Step 1: Use CAD drawing software to outline the spatial curve graphics of the entire area of the sheet metal part to be modeled, generate a set of curve segments A, and save its information to the CAD file. A sheet metal ensemble includes multiple sheet metal parts that are used together in the same batch, such as multiple sheet metal parts that together form a ceiling.

[0028] Step 2: Use Rhino software to open the CAD file obtained in step 1 to obtain the information of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com