Degassing chambers and semiconductor processing equipment

A gas chamber and cavity technology, which is applied in the field of degassing chambers and semiconductor processing equipment, can solve the problems that the temperature of the chamber 1 cannot be the same, the degassing effect of the workpiece S to be processed is different, and the inner wall becomes dirty, so as to eliminate the heating effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

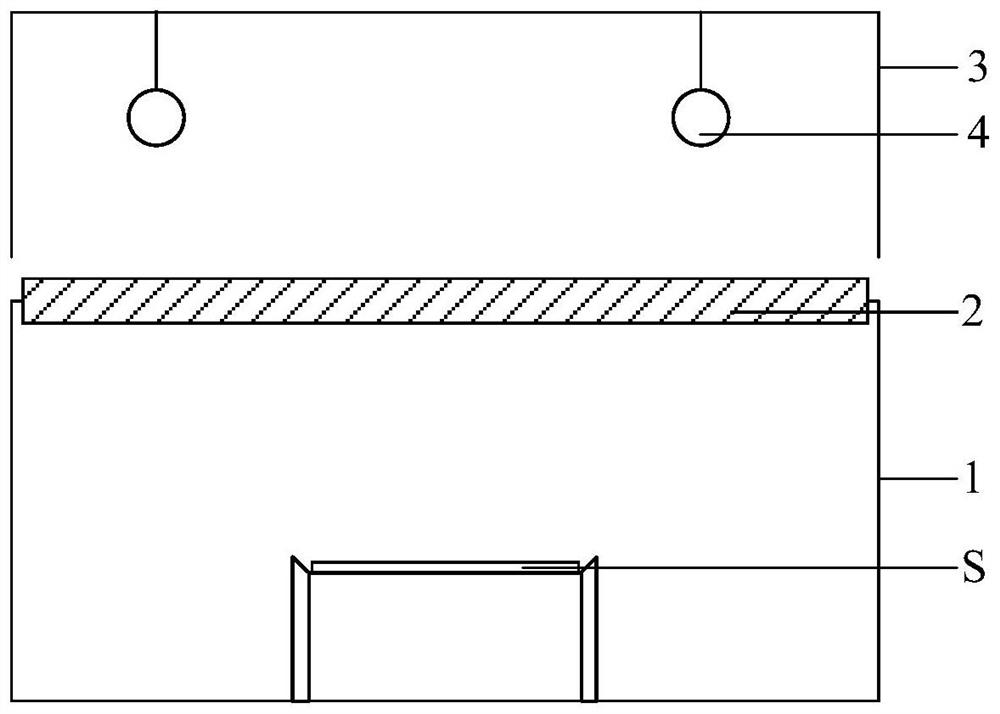

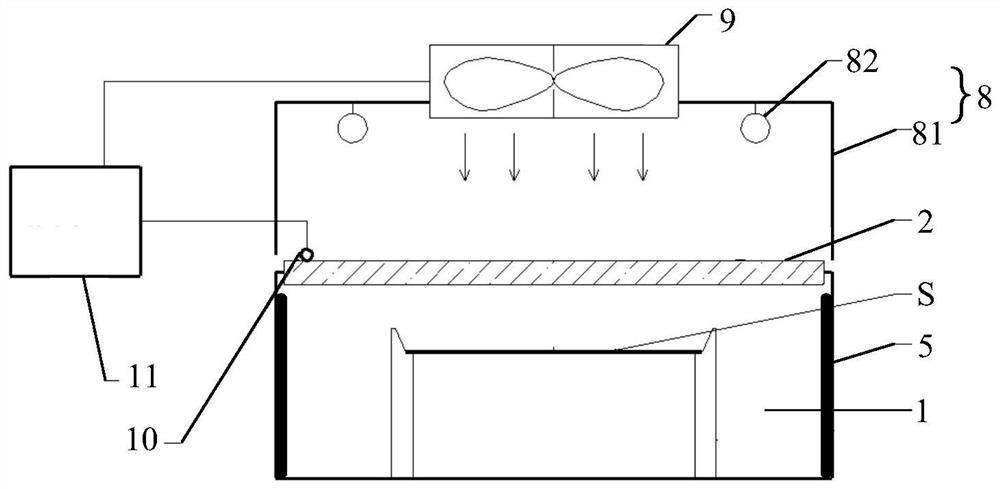

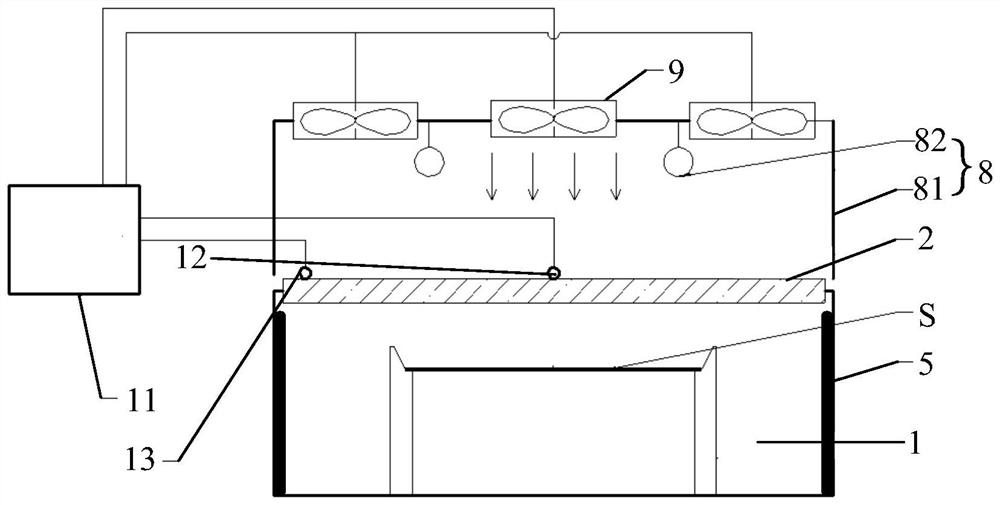

[0026] Please refer to Figure 2 to Figure 5 , the present embodiment provides a degassing chamber, including: a chamber 1 and a heating device 8 arranged on the upper part of the chamber 1, the heating device 8 heats the workpiece S placed in the chamber 1 by emitting light ; The inner wall and / or inner bottom wall of the cavity 1 is provided with an anti-reflection structure, which is used to weaken or eliminate the reflection of light on the inner wall and / or inner bottom wall of the cavity 1 .

[0027] Please refer to figure 2 , a dielectric window 2 is installed on the top wall of the cavity 1, that is, the dielectric window 2 seals the top wall of the cavity 1, so that the cavity 1 forms a closed vacuum chamber; generally, the dielectric window 2 is made of quartz material It is made in a transparent state, so the light emitted by the heating device 8 above the dielectric window 2 can pass through the transparent dielectric window 2 and irradiate the workpiece S in the...

Embodiment 2

[0055] This embodiment provides a semiconductor processing device, including the degassing chamber of Embodiment 1.

[0056] In the semiconductor processing equipment of this embodiment, since an anti-reflection structure is provided on the inner side wall and / or the inner bottom wall of the cavity, the reflection of the light emitted by the heating device by the side wall of the degassing chamber can be weakened or even eliminated, thereby eliminating The heating effect of the heat generated by the reflected light on the workpiece to be processed is eliminated, so that the temperature of the workpiece to be processed no longer decreases as the inner wall of the degassing chamber becomes dirty.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com