Continuous synchronous planet mechanical chemical reactor

A chemical reactor and reactor technology, applied in the field of reactors, can solve the problems of many moving parts, high mechanical failure rate, high speed, etc., and achieve the effect of continuous transportation and realization of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

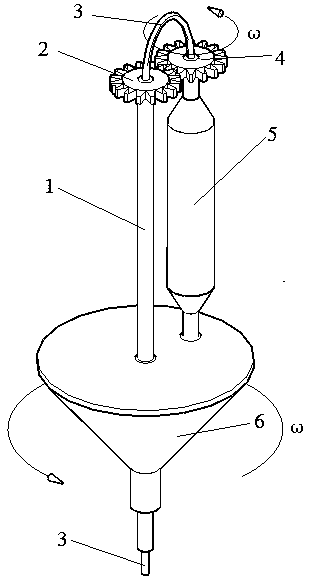

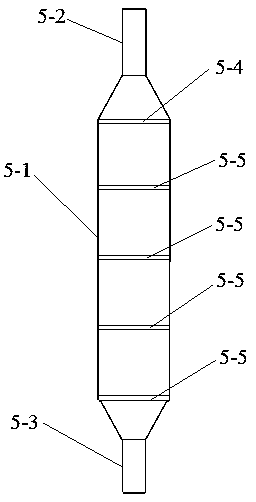

[0023] A continuous synchronous planetary mechanochemical reactor comprising a central shaft tube (1), a central gear (2), a conveying tube bundle (3), a planetary gear (4), a reaction chamber (5) and a conical rotating platform (6); The central axis tube (1) is a hollow tube; the upper end of the central axis tube (1) is fixed with the central gear (2); "core wire", which are respectively liquid delivery pipe, gas delivery pipe and powder material delivery pipe; the reaction chamber (5) is a cylinder (5-1) with tapered heads at both ends, and the cylinder (5-1) One end communicates with the upper round pipe (5-2), and the other end communicates with the lower round pipe (5-3). The material distribution plate (5-4) and 2 ~10 sieve plates (5-5), the above-mentioned material distribution plate (5-4) and 2 sieve plates (5-5) divide the reaction chamber (5) from top to bottom into material distribution chamber and 2 reaction chambers Unit and product collection chamber, planetary...

Embodiment 2

[0027]A continuous synchronous planetary mechanochemical reactor comprising a central shaft tube (1), a central gear (2), a conveying tube bundle (3), a planetary gear (4), a reaction chamber (5) and a conical rotating platform (6); The central axis tube (1) is a hollow tube; the upper end of the central axis tube (1) is fixed with the central gear (2); "core wire", which are respectively liquid delivery pipe, gas delivery pipe and powder material delivery pipe; the reaction chamber (5) is a cylinder (5-1) with tapered heads at both ends, and the cylinder (5-1) One end communicates with the upper round pipe (5-2), and the other end communicates with the lower round pipe (5-3). The material distribution plate (5-4) and 2 ~10 sieve plates (5-5), the above-mentioned material distribution plate (5-4) and 10 sieve plates (5-5) divide the reaction chamber (5) from top to bottom into material distribution chamber and 10 reaction chambers Unit and product collection chamber, planetar...

Embodiment 3

[0031] A continuous synchronous planetary mechanochemical reactor comprising a central shaft tube (1), a central gear (2), a conveying tube bundle (3), a planetary gear (4), a reaction chamber (5) and a conical rotating platform (6); The central axis tube (1) is a hollow tube; the upper end of the central axis tube (1) is fixed with the central gear (2); "core wire", which are respectively liquid delivery pipe, gas delivery pipe and powder material delivery pipe; the reaction chamber (5) is a cylinder (5-1) with tapered heads at both ends, and the cylinder (5-1) One end communicates with the upper round pipe (5-2), and the other end communicates with the lower round pipe (5-3). The material distribution plate (5-4) and 2 ~10 sieve plates (5-5), the above-mentioned material distribution plate (5-4) and 5 sieve plates (5-5) divide the reaction chamber (5) from top to bottom into material distribution chamber, 5 reaction chambers The unit and the product collection chamber, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com