Three-dimensional flowered composite photocatalyst for sewage treatment and preparation method

A three-dimensional flower-like, sewage treatment technology, applied in catalyst activation/preparation, light water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of low photocatalytic activity, limited absorption range, small specific surface area, etc. , to achieve high photocatalytic activity, improve catalytic effect, and increase the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

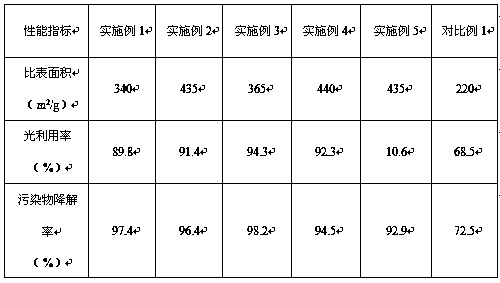

Examples

Example Embodiment

[0029] Example 1

[0030] (1) Dissolve sodium carbonate in water, freeze into ice and crush to form ice blossoms, then add soluble calcium salt, stir to dissolve, add additives, heat in a constant temperature water bath, stir for a certain time, filter, and use distilled water and absolute ethanol Washing, drying in an oven to obtain micron-scale flower-like calcium carbonate crystals; the temperature of the constant temperature water bath is 30°C; the reaction time is 70min; the drying temperature of the oven is 80°C; each raw material is calculated by weight: 30 parts of soluble calcium salt, 25 parts of sodium carbonate, 10 parts of additives, 35 parts of water; soluble calcium salt is calcium chloride; additive is citric acid;

[0031] (2) Put the flower-shaped calcium carbonate crystal and molybdenum disulfide target obtained in step (1) into a vacuum chamber, turn on the pulsed laser, and focus the laser beam on the molybdenum disulfide target through the lens and optical win...

Example Embodiment

[0033] Example 2

[0034] (1) Dissolve sodium carbonate in water, freeze into ice and crush to form ice blossoms, then add soluble calcium salt, stir to dissolve, add additives, heat in a constant temperature water bath, stir for a certain time, filter, and use distilled water and absolute ethanol Washing and drying in an oven to obtain micron-scale flower-like calcium carbonate crystals; the temperature of the constant temperature water bath is 25°C; the reaction time is 80min; the drying temperature of the oven is 70°C; each raw material is calculated by weight: 25 parts of soluble calcium salt, 22 parts of sodium carbonate, 8 parts of additives, 45 parts of water; the soluble calcium salt is calcium acetate; the additive is tartaric acid;

[0035] (2) Put the flower-shaped calcium carbonate crystal and molybdenum disulfide target obtained in step (1) into a vacuum chamber, turn on the pulsed laser, and focus the laser beam on the molybdenum disulfide target through the lens and ...

Example Embodiment

[0037] Example 3

[0038] (1) Dissolve sodium carbonate in water, freeze into ice and crush to form ice blossoms, then add soluble calcium salt, stir to dissolve, add additives, heat in a constant temperature water bath, stir for a certain time, filter, and use distilled water and absolute ethanol Washing and drying in an oven to obtain micron-scale flower-like calcium carbonate crystals; the temperature of the constant temperature water bath is 35°C; the reaction time is 60min; the drying temperature of the oven is 90°C; each raw material is calculated by weight: 35 parts of soluble calcium salt, 28 parts of sodium carbonate, 12 parts of additives, 2 parts of water; the soluble calcium salt is calcium sulfate; the additives are succinic acid and malic acid;

[0039] (2) Put the flower-shaped calcium carbonate crystal and molybdenum disulfide target obtained in step (1) into a vacuum chamber, turn on the pulsed laser, and focus the laser beam on the molybdenum disulfide target thro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap