Clamping device for workpiece punching

A clamping device and punching technology, which is applied in the field of clamping devices for punching workpieces, and can solve problems such as low punching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

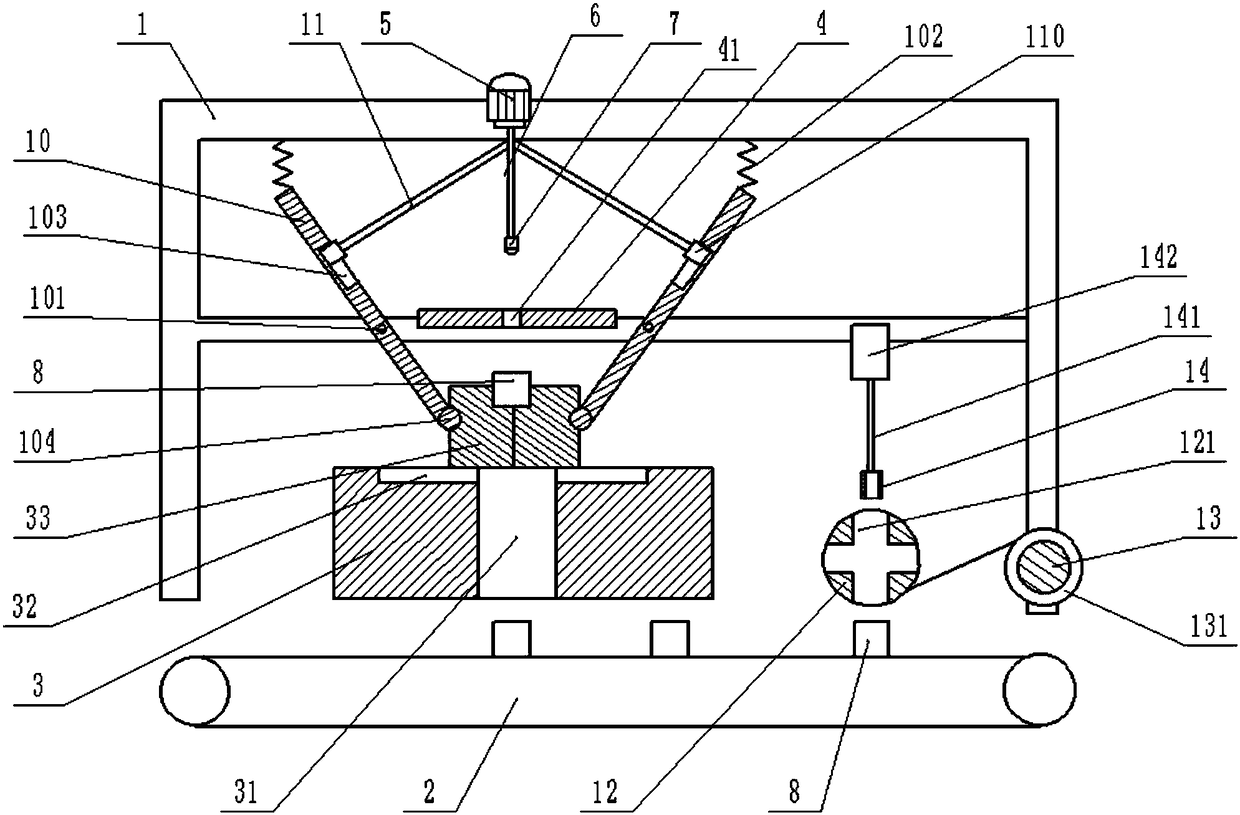

[0021] The reference signs in the drawings of the description include: frame 1, conveyor belt 2, base 3, discharge hole 31, chute 32, clamp block 33, positioning plate 4, positioning hole 41, first cylinder 5, first piston rod 6. Punch 7, punching die 8, first push rod 10, hinge point 101, spring 102, groove 103, ball head 104, second push rod 11, slider 110, film sticking roller 12, communication hole 121, Unwinding roller 13, film roll 131, film sticking column 14, second piston rod 141, second cylinder 142.

[0022] The embodiment is basically as attached figure 1 Shown:

[0023] A fixture for punching a workpiece, including a frame 1, a punching unit and a film sticking unit, wherein:

[0024] The punching station includes a conveyor belt 2, a base 3, a clamping part, a positioning plate 4 and a punching machine. The upper surface of the conveyor belt 2 is covered with a layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com