Mixing and agitating device for raw material for producing tunnel brick

A technology for mixing and mixing raw materials, which is applied to cement mixing devices, liquid ingredient supply devices, clay preparation devices, etc., can solve the problems of single mixing form, poor mixing uniformity, complex structure, etc., and achieve improved mixing uniformity and manufacturing The effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

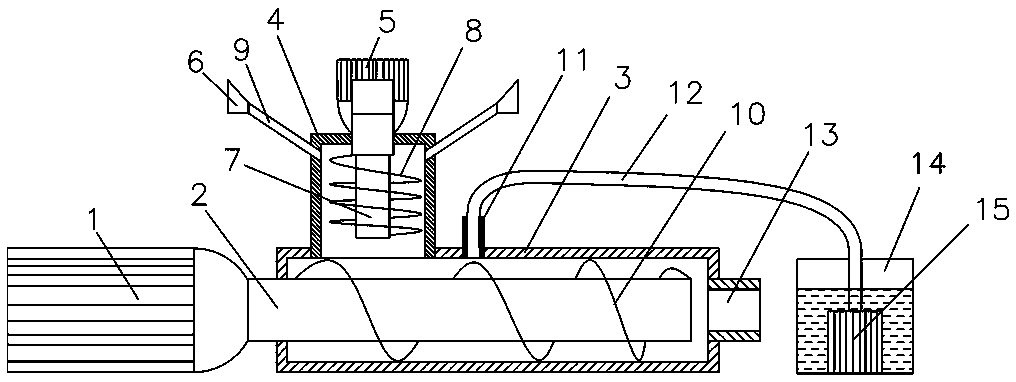

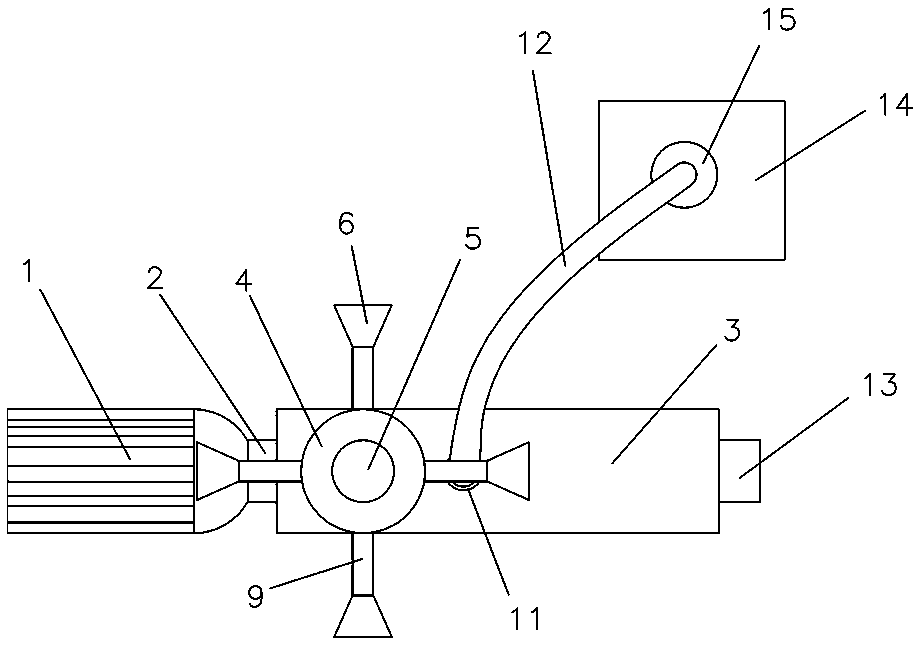

[0020] Example 1, such as Figure 1-2 Shown:

[0021] A mixing and stirring device for raw materials for tunnel brick production, comprising a first motor 1 and a first mixing drum 3, the first motor 1 is connected with a first mixing shaft 2, and the first mixing shaft 2 extends into the first mixing drum 3, and the outer surface of the first mixing shaft 2 is provided with a first spiral blade 10; the top of the first mixing drum 3 close to the end of the first motor 1 is vertically provided with a second mixing drum 4; The top of the drum 4 is vertically arranged with a second motor 5, and the lower end of the second motor 5 is connected with a second stirring shaft 7 which extends into the second stirring drum 4 and the outer surface of the second stirring shaft 7 A second spiral blade 8 is provided; the upper periphery of the second mixing drum 4 is arrayed with 4-10 feeding channels 9 inclined to the axis of the second mixing drum 4, and the outer end of the feeding channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com