A kind of manufacturing method of textile fiber artwork

A technology of textile fiber and production method, which is applied in the field of textile fiber art production, and can solve problems such as poor practicality, insufficient three-dimensional visual effect of the product, and difficulty in cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

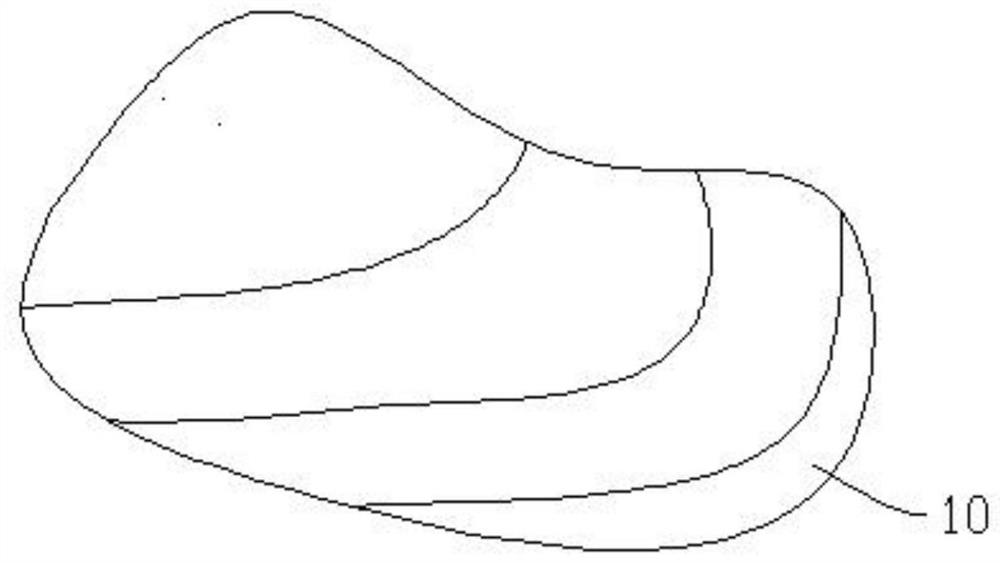

[0026] A piece of textile fiber three-dimensional grass field scene carpet is made by adopting the manufacturing method of textile fiber artwork of the present invention. The base material is non-woven fabric 10 (flat base material), and the textile fiber is woolen yarn. like figure 1 As shown, the shape of a piece of grass is first drawn on the non-woven fabric 10, and the color blocks of the base map are divided into four colors: dark green, green, light green, and light green. After drawing, decompose and number the base map, cut off the excess leftover material, and then cut out the required wool yarns 20 (textile fibers) of various colors from the ingredients. like figure 2 As shown, the woolen yarn 20 is respectively pasted on the corresponding color blocks according to the pattern number, and the connecting glue 30 is located between the woolen yarn 20 and the non-woven fabric 10, and is pressed for a moment to fix it so that it does not fall off. Then if image 3 ...

Embodiment 2

[0028] A textile fiber landscape tree is made by adopting the manufacturing method of the textile fiber artwork of the present invention. Foam base with trim shape. Then select the green wool, cut it, tie it up, and insert a small rod in the middle. Then insert the other end of the bundled wool rod into the foam, and insert the entire foam in turn; finally insert the bottom and fix a thick branch with glue. Such a vibrant wool tree is made.

Embodiment 3

[0030] A textile fiber room type storage box is made by adopting the manufacturing method of the textile fiber artwork of the present invention. The base material is plastic grid, designed and sewn into a house shape, and the top of the house is designed to be opened and closed. Choose fine wool as the wire material. On the surface of the three-dimensional house substrate, draw a base map and number the colors well, then cut the woolen yarns of various colors; paste the woolen yarns on the house according to the numbers until the roof and walls of the whole house are completely glued, and then trim out the layering according to the light and shade of the color , and finally remove impurities. Such a practical wool storage box is made, which is practical and beautiful.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com