Hub type independent wheel bogie

An independent wheel and bogie technology, applied in the direction of the bogie, the device for lateral relative movement between the underframe and the bogie, and the parts of the railway car body. and other problems, to achieve the effect of small wheel-rail friction, reducing unsprung mass and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

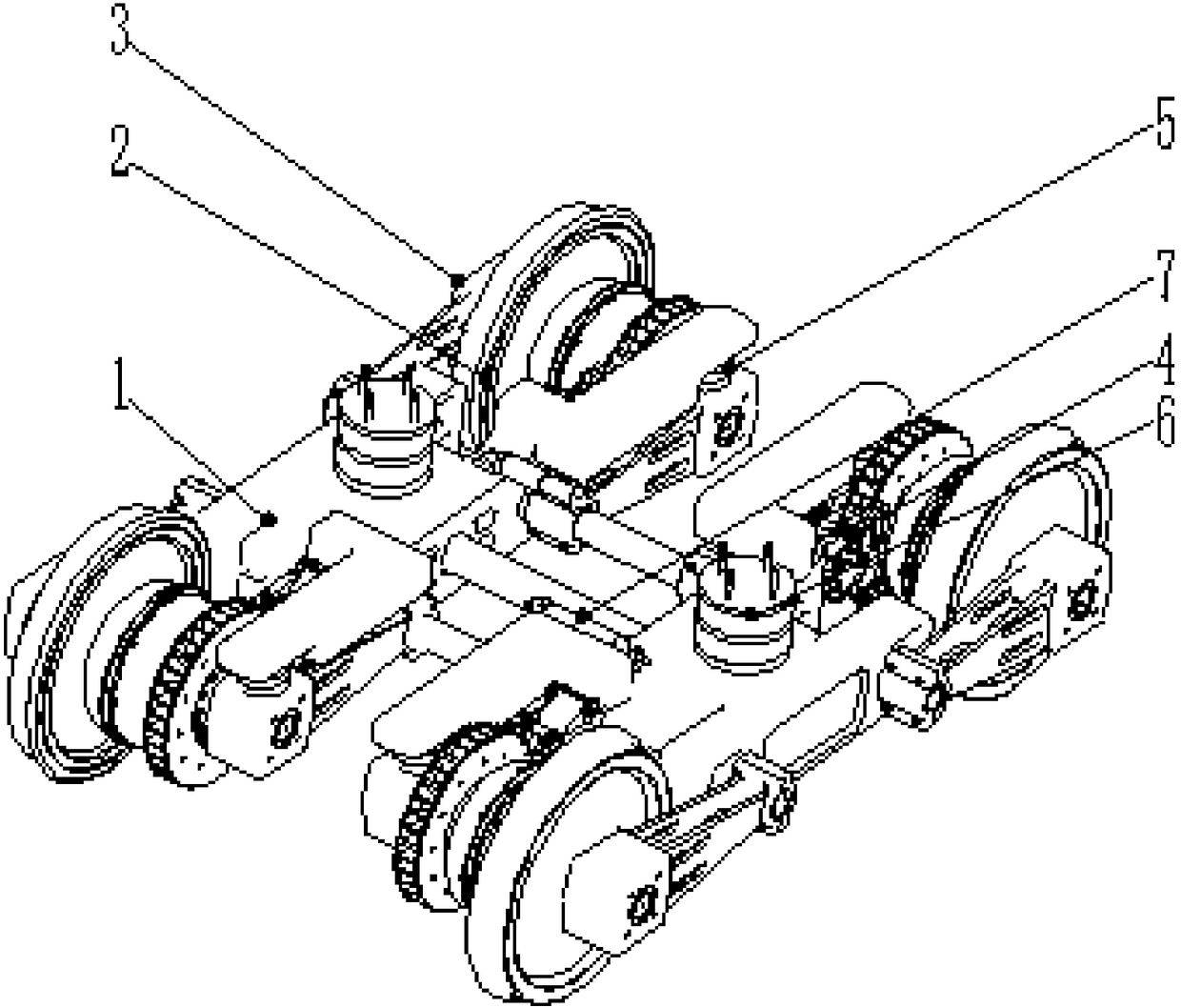

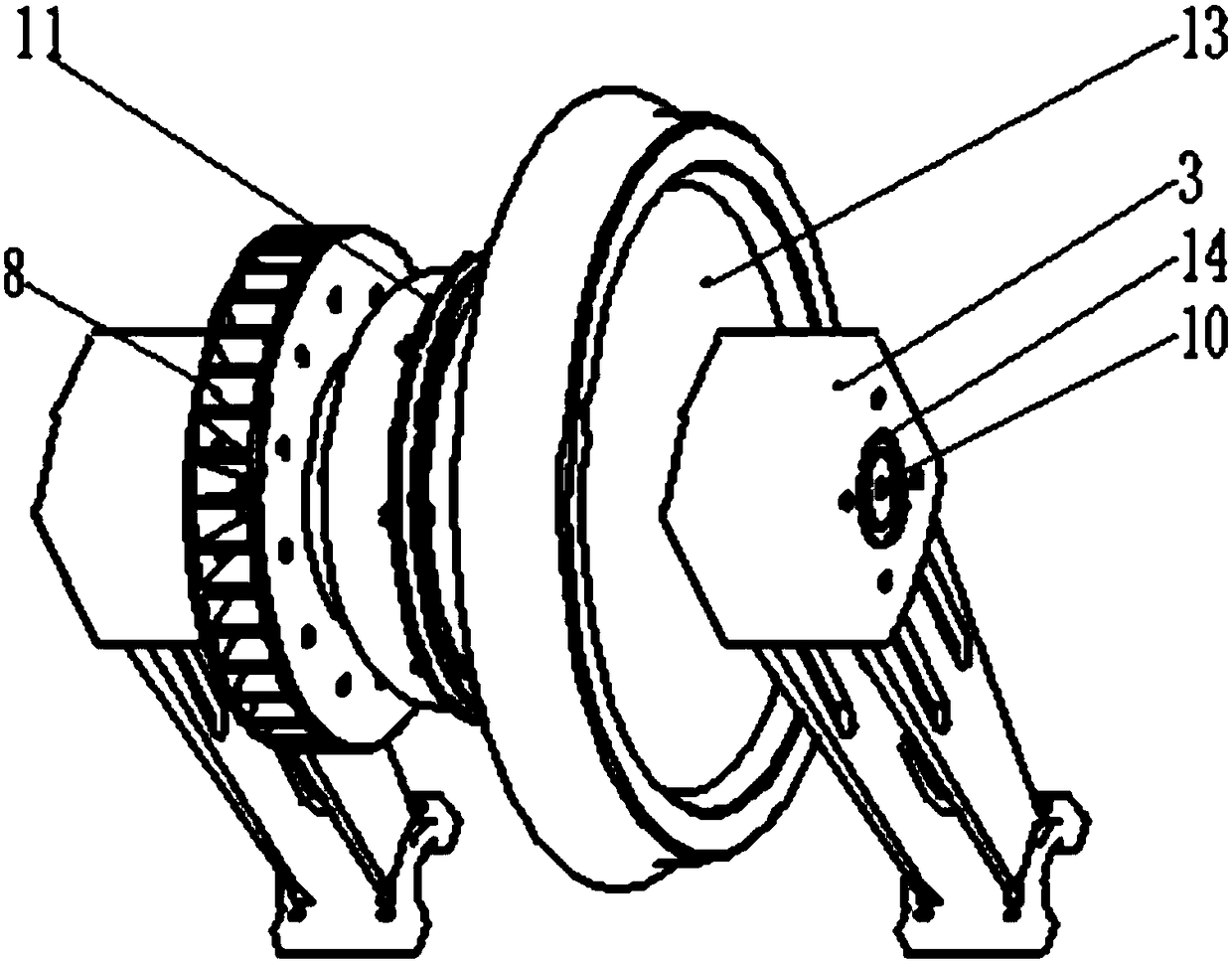

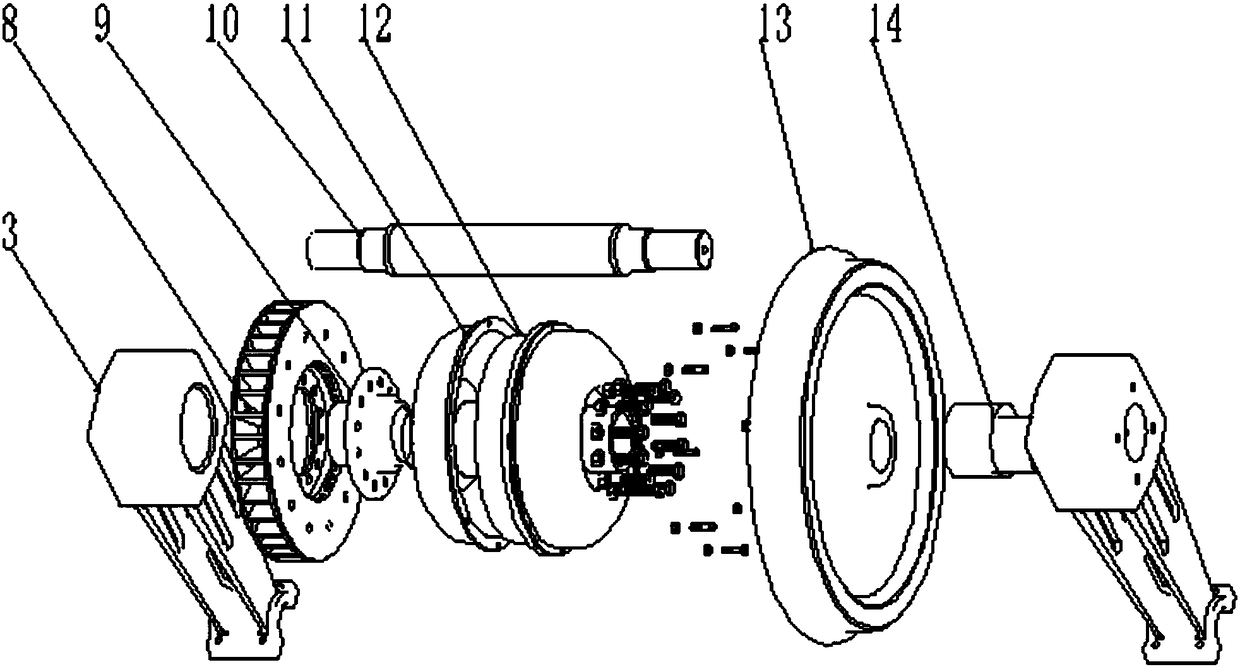

[0037] The specific embodiment of the present invention is shown in the accompanying drawings, the hub-type independent wheel bogie includes: frame 1, independent wheel pair 2, axle box 3, brake caliper 4, primary suspension 5, air spring 6, lateral oil pressure reducer Vibrator 7 and sensor;

[0038] The frame 1 includes: two symmetrically arranged side frames, a central beam and two side beams; the side frame is an H-shaped welded structure, and a mounting seat for the air spring 6 is arranged on the upper part, and a brake caliper 4 is installed at the end. The mounting seat, and the mounting seat of the transverse oil pressure shock absorber 7; the central beam and the two side beams are all made of seamless steel pipe structure; the two ends of the side beam protrude from the side frame, which is used to install the axle box 3;

[0039] The independent wheel set 2 is installed on the side frame of the frame 1 through the axle box body 3 and the primary suspension 5;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com