Transverse and vertical material connecting structure for glass curtain wall

A technology for connecting structures and glass curtain walls, applied in the direction of walls, building components, building structures, etc., can solve the problems of low construction positioning efficiency, poor torsion resistance, etc., to reduce labor costs and material costs, less processing volume, and effective beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

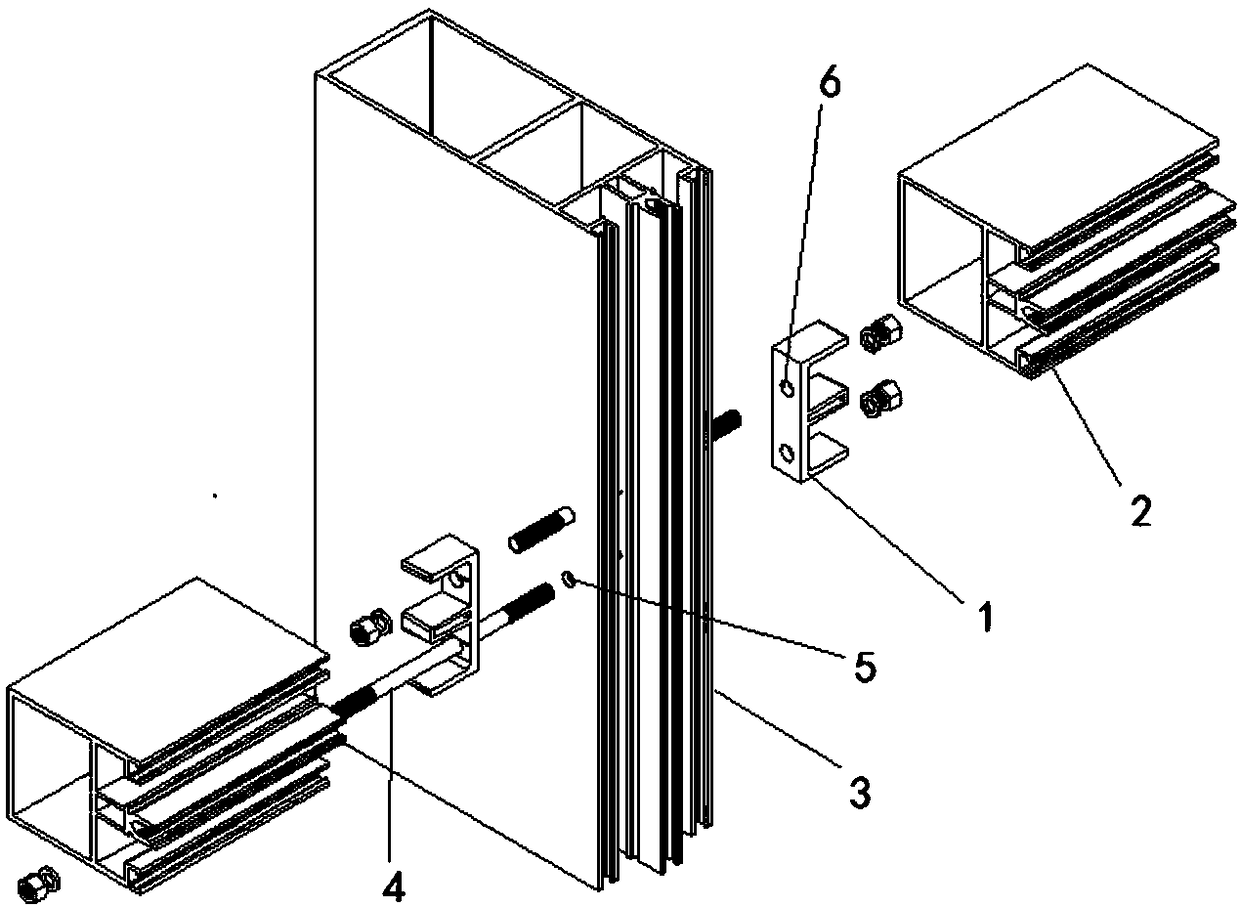

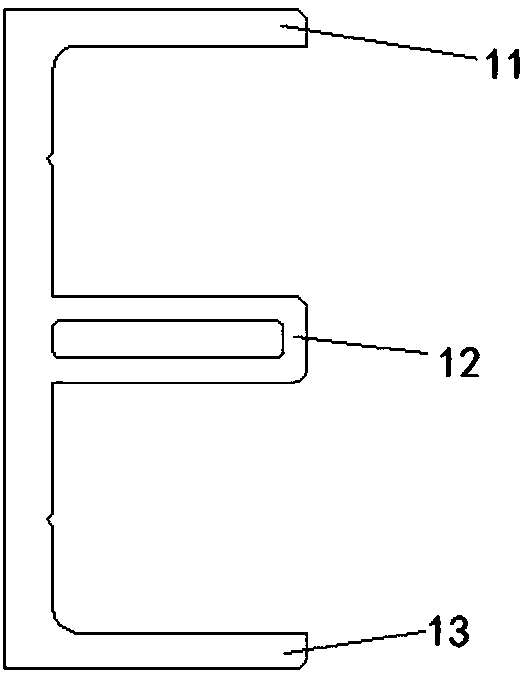

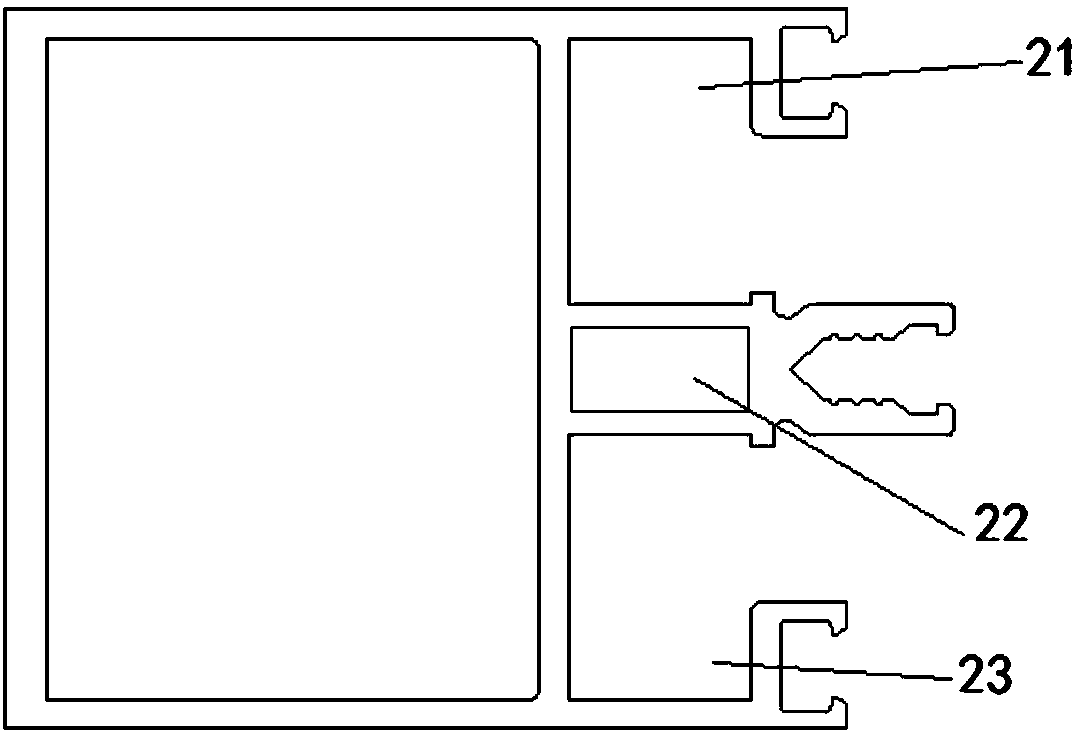

[0021] The horizontal and vertical material connection structure of the glass curtain wall in this embodiment includes a mountain-shaped connecting piece 1, a beam 2, a column 3 and a screw rod 4, and the vertical column 3 is provided with two sets of mounting holes 5 that pass through from left to right. The bottom plate of the mountain-shaped connecting piece 1 There are two sets of upper and lower fixing holes 6 corresponding to the installation holes; the beam 2 is provided with an upper notch 21, a middle notch 22 and a lower notch 23 from top to bottom, and the upper forward notch 11 of the mountain-shaped connector 1 , the middle forward notch 12 and the lower forward notch 13 are respectively inserted into the upper notch 21, the middle notch 22 and the lower notch 23 of the beam; there is a group of mountain-shaped connectors 1 on the left and right sides of the column 3, and the screw rod 4 The entire column 3 is penetrated along the mounting hole 5, and the two ends ...

Embodiment 2

[0024] The connection structure of the horizontal and vertical materials of the glass curtain wall in this embodiment is the same as that of the first embodiment except for the following differences: the middle forward notch 12 of the mountain-shaped connector 1 is a hollow structure, which further enhances the anti-torsion performance and improves the stability; One end is a free end, and the other end is a closed end. When installing, it does not distinguish between positive and negative, and the nut at the free end is imprisoned to achieve fixation.

Embodiment 3

[0026] The horizontal and vertical material connection structure of the glass curtain wall in this embodiment is the same as the first embodiment except for the following differences: the front ends of the upper notch 21, the middle notch 22 and the lower notch 23 of the crossbeam 2 are provided with door-shaped clamping grooves, which are convenient for installing arcs. Shape gusset plate; Upright column 3 is provided with left notch 31, middle notch 32 and right notch 33 successively from left to right, prevents that twisting occurs after the glass is installed, and cross bar is inclined.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com