Stator iron core of brushless motor and brushless motor

A stator core and brushless motor technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of large stator and inconvenient positioning of the stator, so as to avoid circular rotation, ensure long-term low-noise operation, and facilitate The effect of installation positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

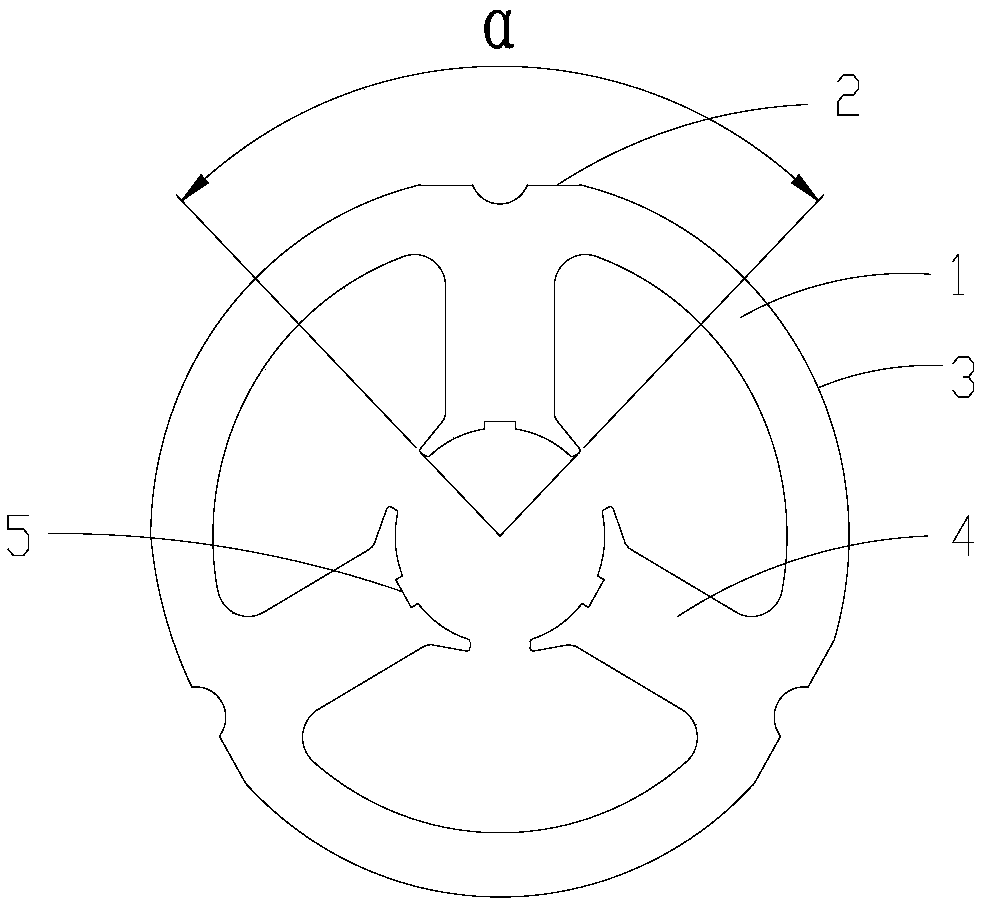

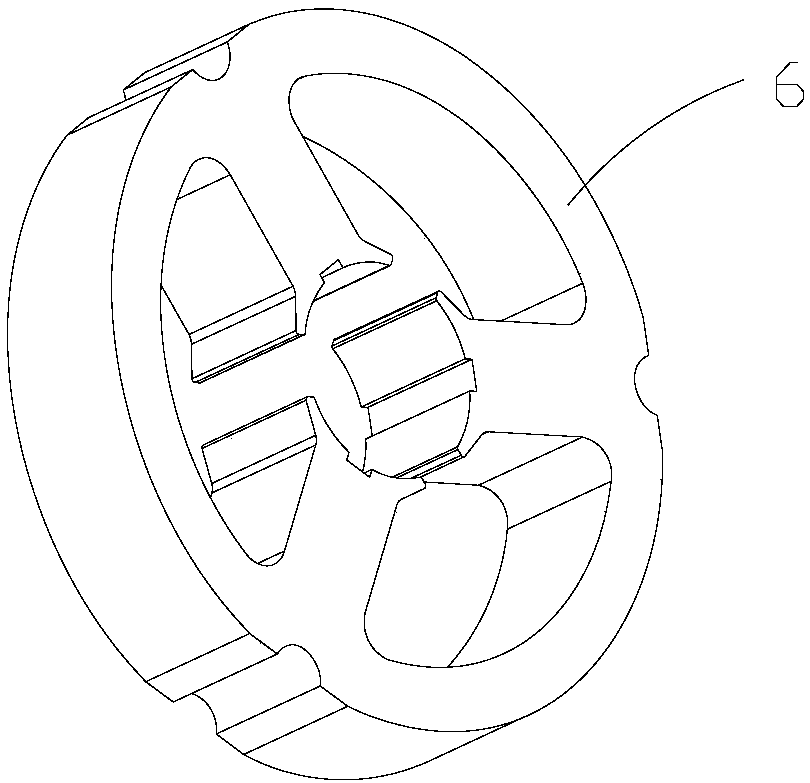

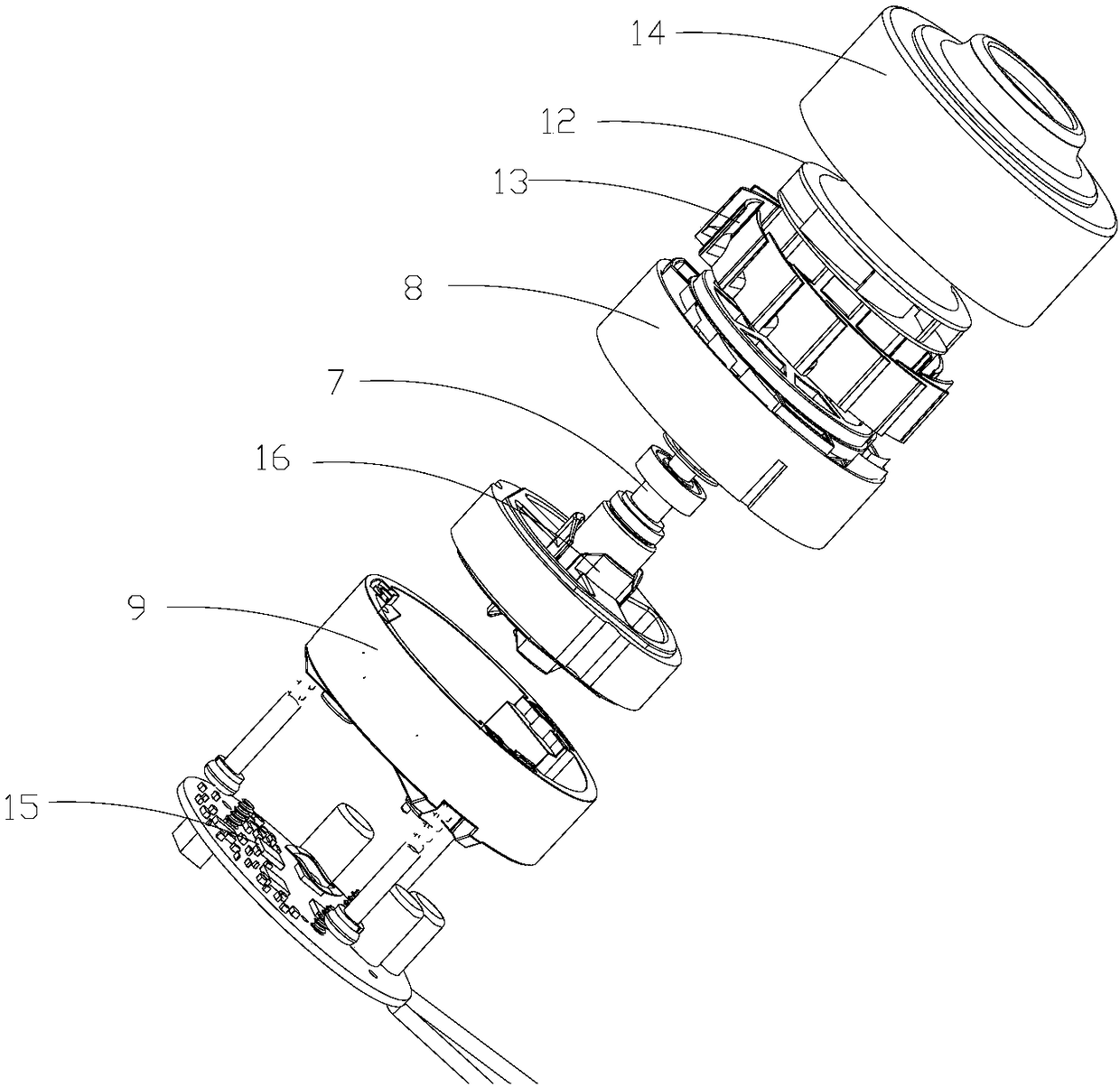

[0030] The present invention provides a brushless motor stator core, which includes an annular yoke 1 and a plurality of teeth 4 extending toward the axis of the yoke 1, and the plurality of teeth 4 are uniform along the inner circle of the yoke 1 The distribution also includes the positioning side 2 on the outer ring of the yoke 1, the positioning side 2 is a straight side, the adjacent side of the positioning side 2 on the yoke 1 is an arc-shaped side 3, and the arc-shaped side 3 forms a pole shoe, and the pole shoe angle The range α is 80°‐89.5°.

[0031] The beneficial effects are: the present invention can realize a smaller size design by providing a positioning edge on the outer ring of the yoke, and the positioning edge is a straight edge, and the adjacent edge of the positioning edge is an arc edge. The combined positioning of the shape edge achieves more accurate positioning, and the commutation performance of the brushless motor is improved by setting the pole shoe a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com