How to make salt casings

A production method and technology of salt casings, which are applied to sausage casings, making sausage casings, cleaning intestines, etc., can solve problems such as difficulty in meeting large-scale industrial production, inconsistent cleaning quality, and harsh working environment, and meet the requirements of large-scale industrial production , Guarantee cleaning quality and save labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

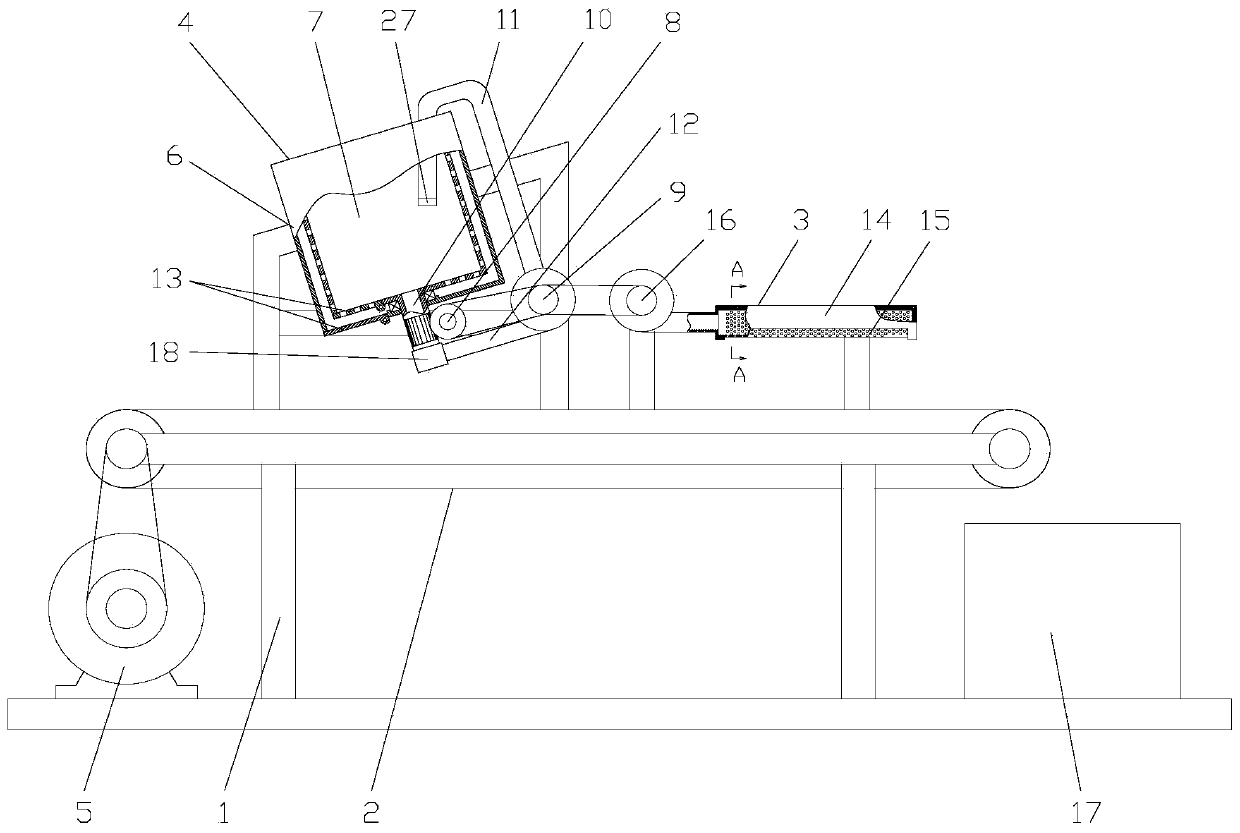

[0027] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

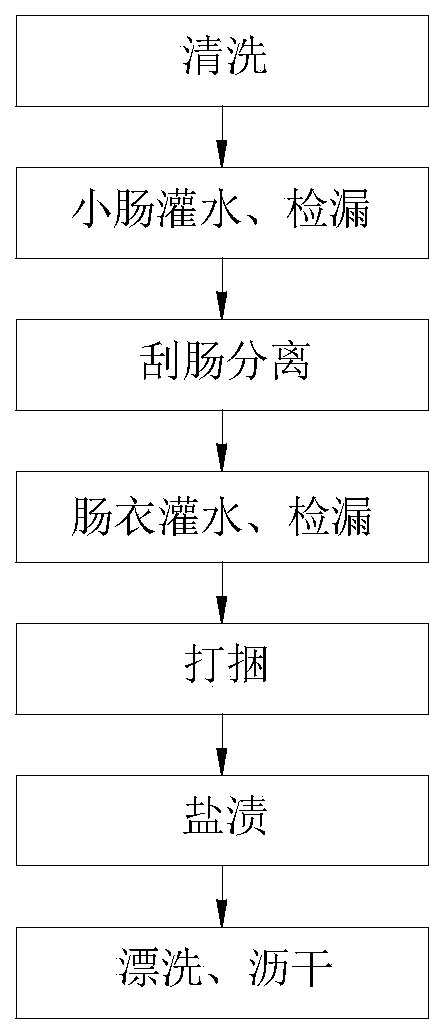

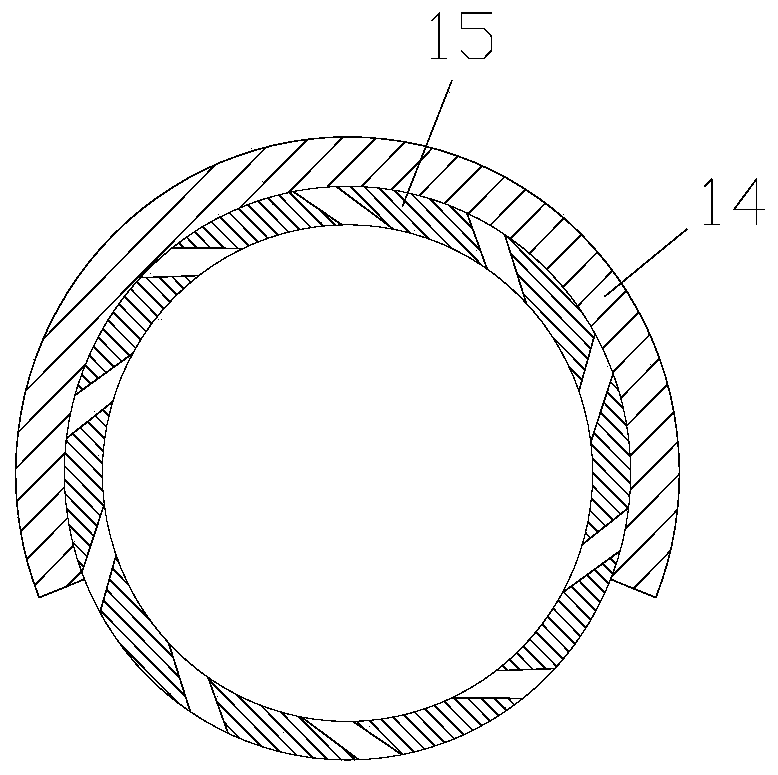

[0028] figure 1 It is a flow chart of the salt casing making method of the present invention; figure 2 It is a schematic diagram of the structure of the washing machine; image 3 for figure 2 Middle A-A sectional view; Figure 4 It is a schematic diagram of the structure of the rotary joint; as shown in the figure: the method for making the salt casing of the present embodiment includes the following steps:

[0029] a. Clean and straighten the small intestine; b. Fill the small intestine with water to clean its interior, and at the same time judge whether there is a leak in the small intestine according to wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com