Efficient sand screening machine used for buildings

A sand screening machine and construction technology, applied in the field of construction machinery, can solve the problems of high labor consumption, clogging of the screen, heavy labor, etc., and achieve the effects of ensuring screening quality, improving sand screening quality, and ensuring efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

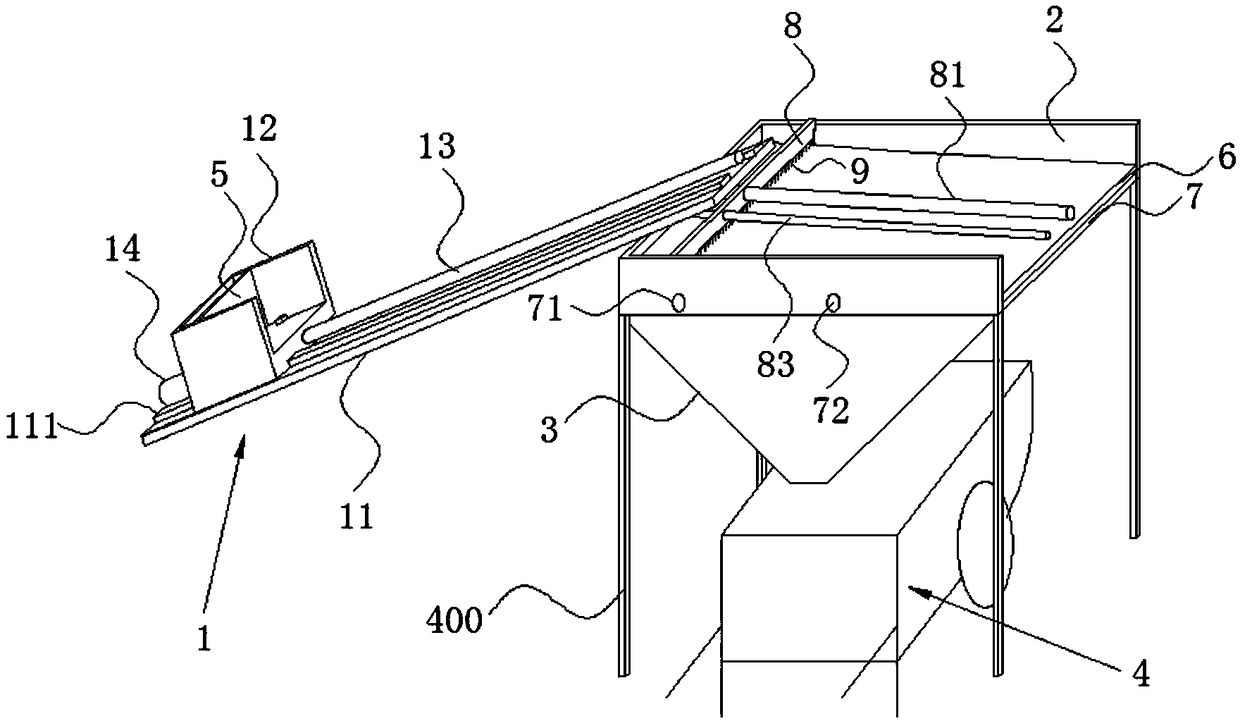

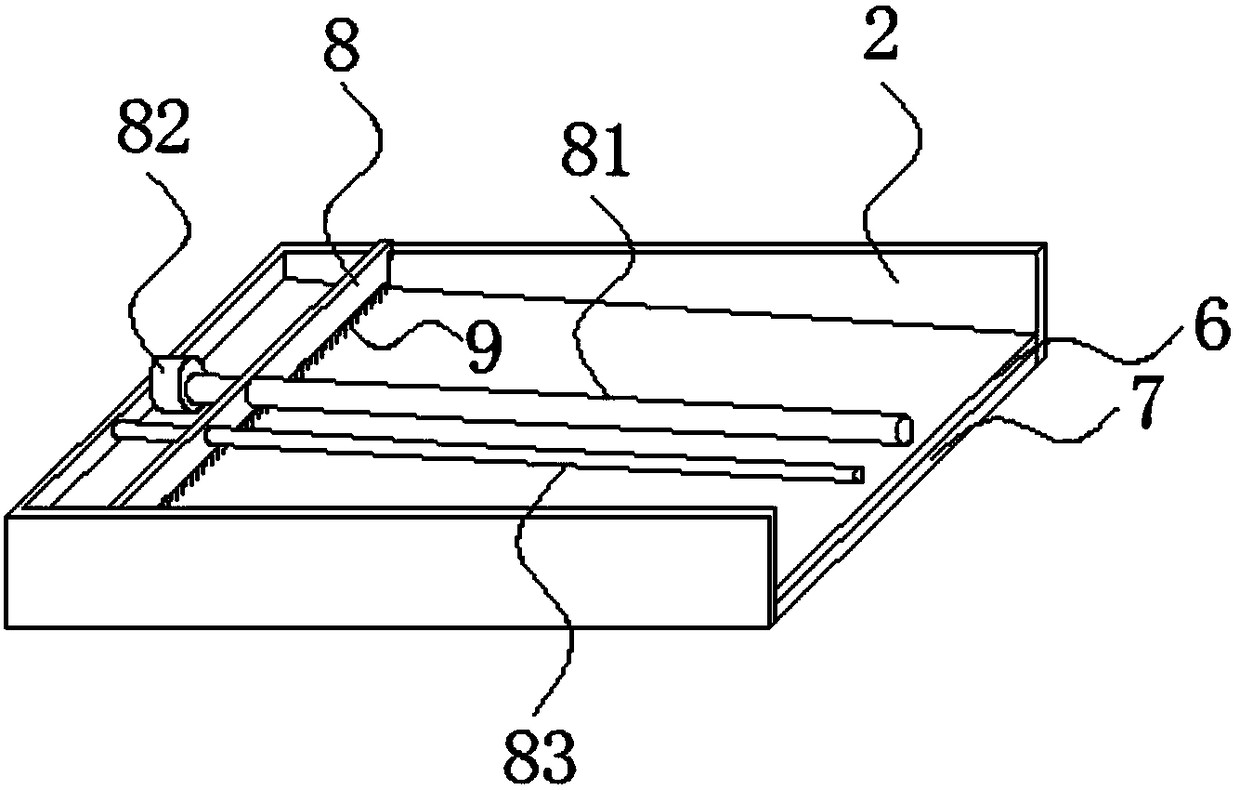

[0033] Example: a high-efficiency sand screening machine for construction, such as Figure 1-Figure 6 As shown, according to the sand screening process, it sequentially includes a feeding mechanism 1, a sand screening tank 2, a sand bucket 3 and a hand-overturned bucket truck 4. The feeding mechanism 1 is located upstream of the sand screening tank 2, and the sand bucket 3 is located below the sand screening tank 2, and the sand bucket 3 is communicated with the sand screening tank 2, and the hand-overturned bucket truck 4 is located below the sand bucket 3;

[0034] During specific implementation, the sand screening tank 2 is fixed on the ground through a support rod 400;

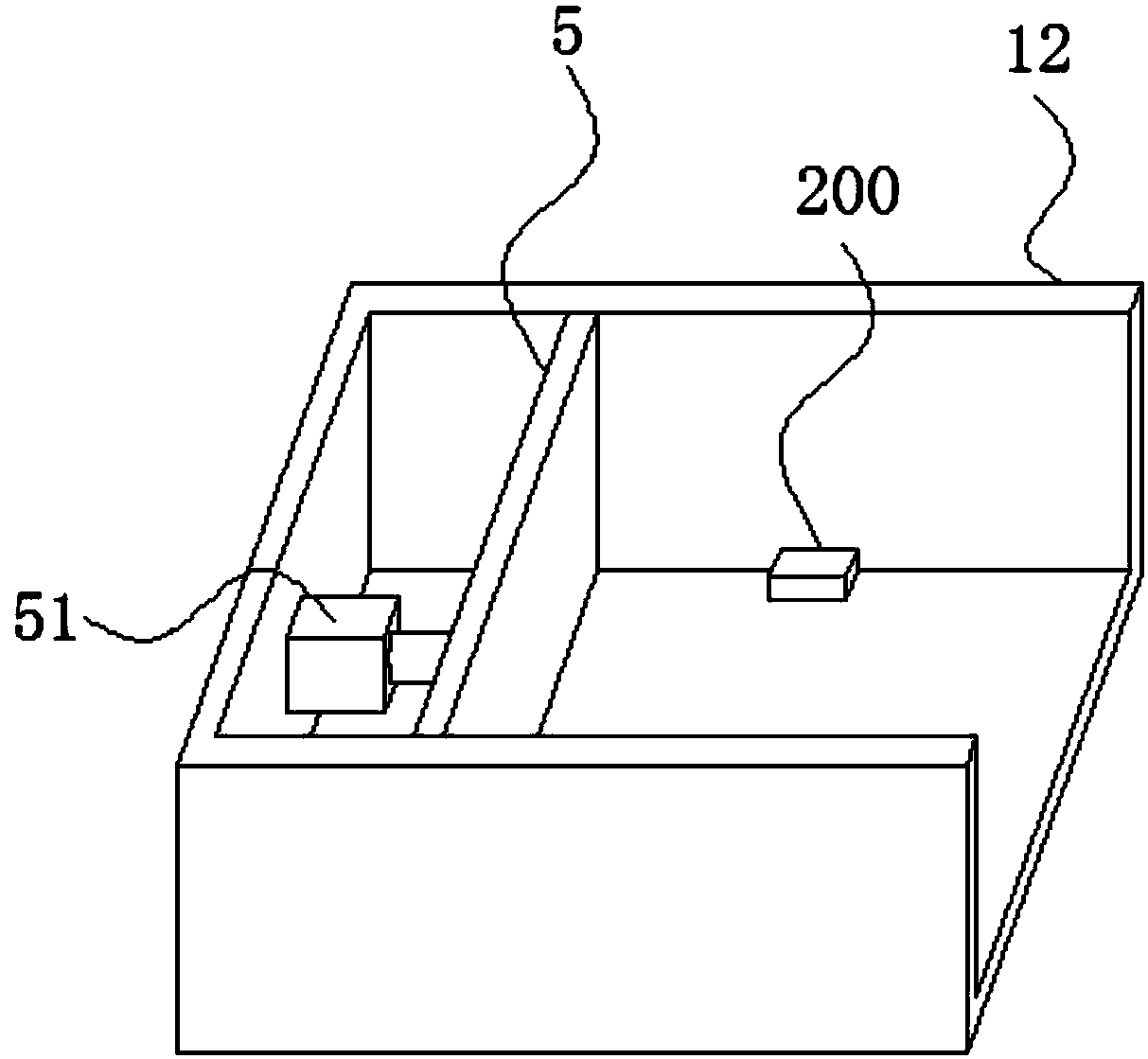

[0035]The feeding mechanism 1 includes a supporting plate 11 , a sand feeding chute 12 , a first screw rod 13 and a feeding driving motor 14 that drives the sand feeding chute 12 to move along the length direction of the supporting plate 11 . The sand tank 12 is located above the support plate 11 , the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com