Bearing processing device

A kind of bearing processing and bearing technology, which is applied in the field of bearing processing devices, can solve the problems of increased mold demand, shallow concave-convex grooves, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is further described in detail through specific implementation methods:

[0023] The reference signs in the accompanying drawings of the specification include:

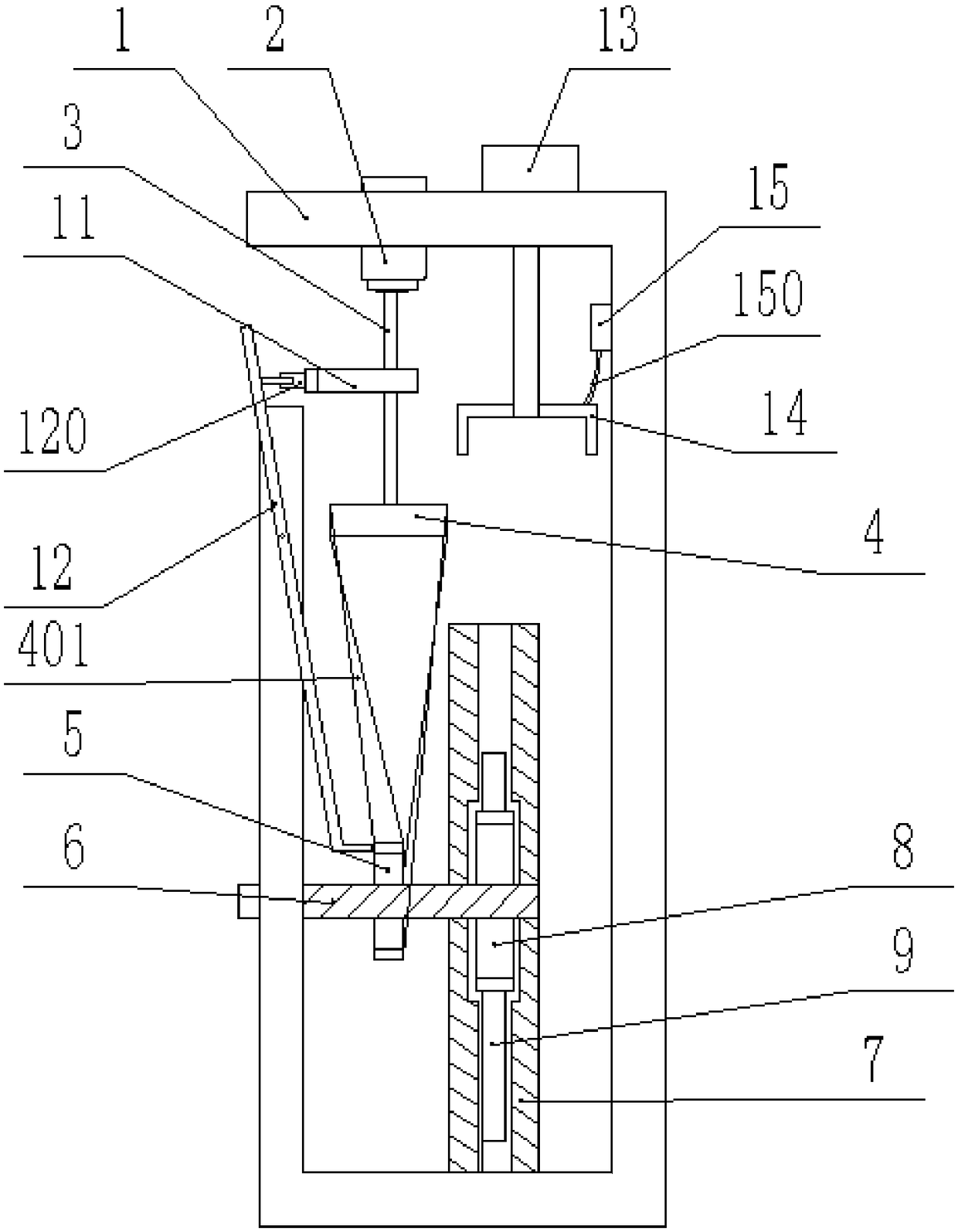

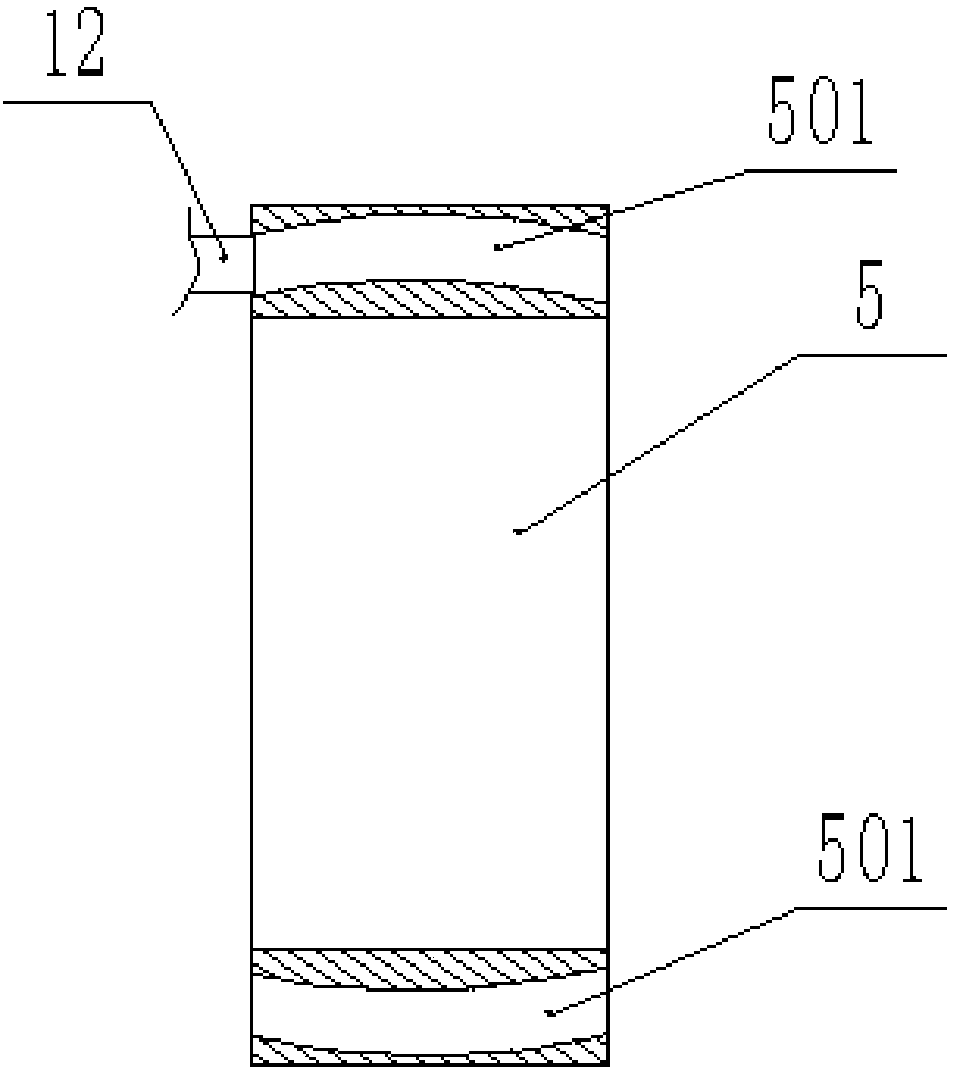

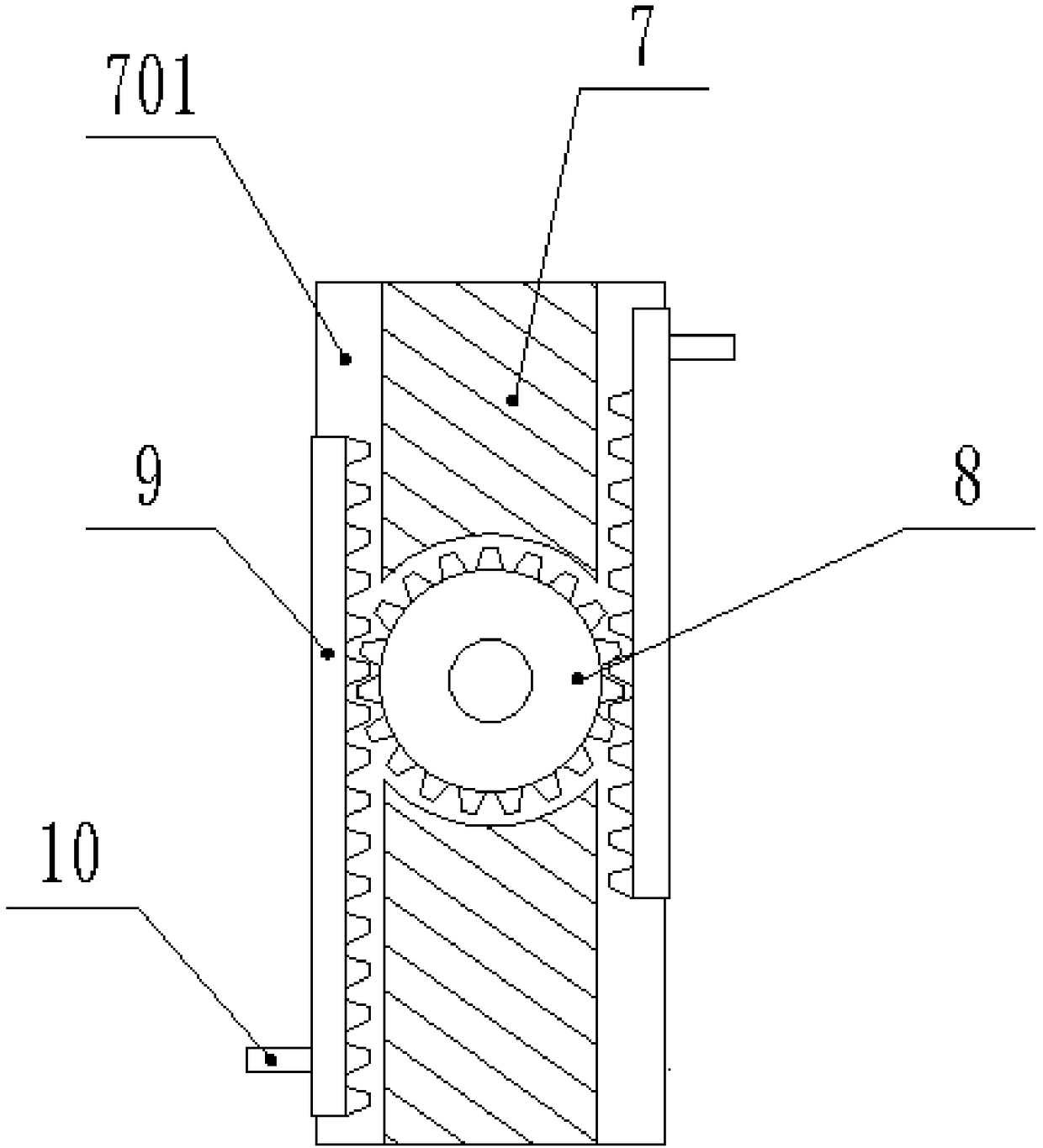

[0024] Frame 1, servo motor 2, first shaft 3, main timing pulley 4, timing belt 401, slave timing pulley 5, locking hole 501, second shaft 6, fixed block 7, installation groove 701, gear 8, Rack 9, cutter 10, cam 11, pin shaft 12, roller 120, driving part 13, jaw 14, oil tank 15, oil outlet pipe 150.

[0025] The embodiment is basically as attached figure 1 , attached figure 2 And attached image 3 Shown:

[0026] The bearing processing device includes a frame 1, a processing unit and a fixing unit. The processing unit includes a driving part 13, a processing part and a locking part. The driving part 13 includes a servo motor 2, a first rotating shaft 3, a second rotating shaft 6, and a main timing belt. Wheel 4 and synchronous pulley 5, servo motor 2 are fixed on the frame 1, the first rota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com