Combined type magnetron sputtering cathode

A magnetron sputtering and composite technology, applied in the direction of sputtering plating, ion implantation plating, coating, etc., can solve the problems of inflexible adjustment and low utilization rate of targets, so as to improve the utilization rate of targets, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

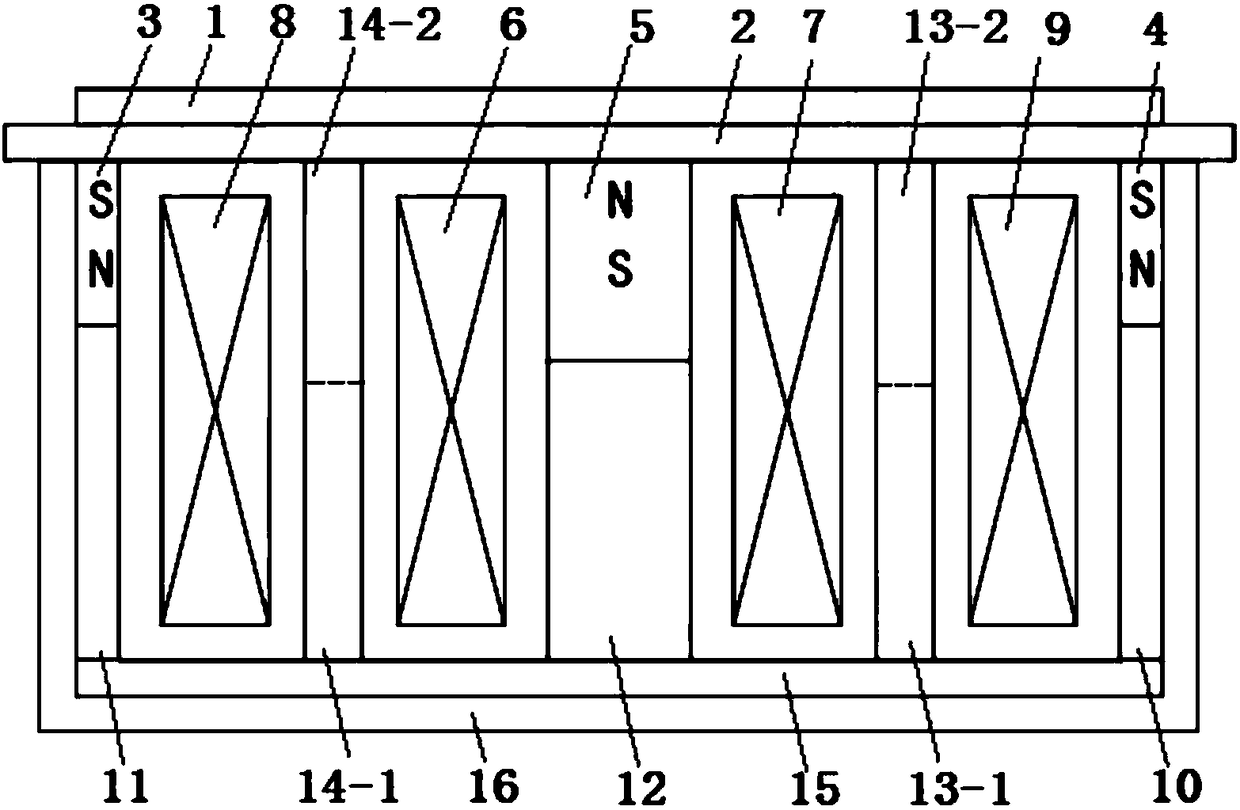

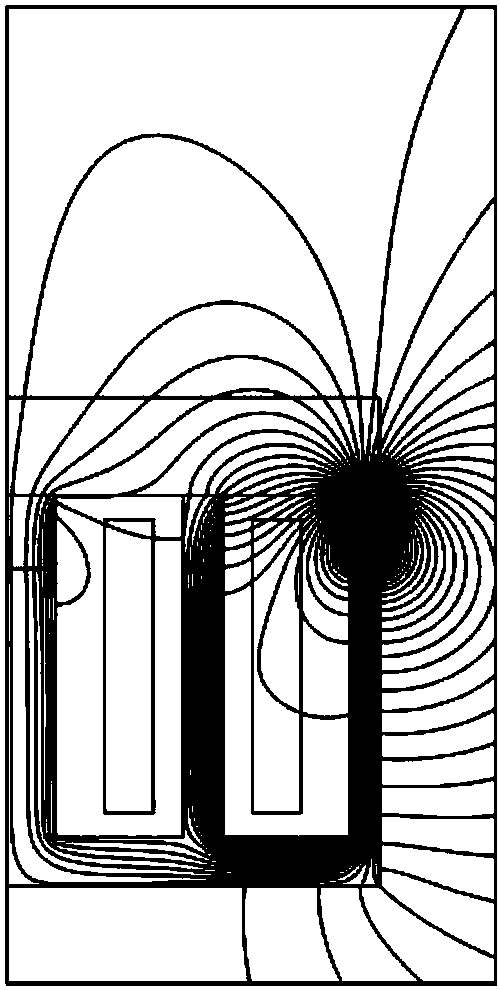

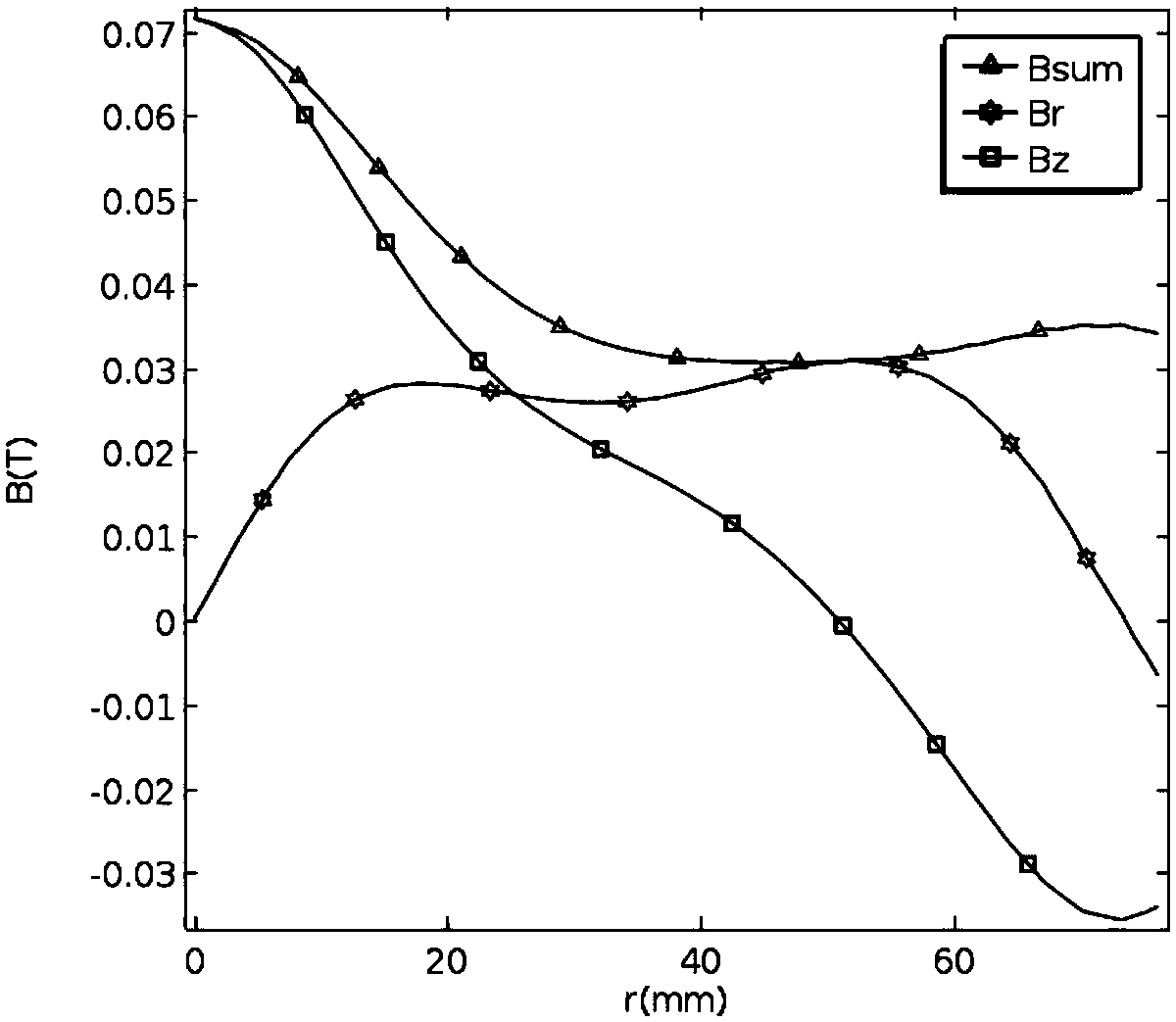

[0029] figure 1 It is a composite magnetron sputtering device of the present invention. like figure 1 As shown, the magnetron sputtering cathode is rectangular and planar, and consists of a planar target 1, a water-cooled back plate 2, outer permanent magnets 3 and 4, inner permanent magnets 5, inner electromagnetic coils 6 and 7, and outer electromagnetic coils. 8 and 9, outer yokes 10 and 11, inner yoke 12, middle yokes 13 and 14, bottom yoke 15 and frame 16 constitute. The water-cooled back plate 2 is installed below the flat target 1, and the upper surface of the water-cooled back plate is provided with a groove, and the groove is filled with cooling water. The outer permanent magnets 3 and 4 are installed under the water-cooled back plate 2 , and the two outer permanent magnets 3 and 4 are placed symmetrically about the center line of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com