Combustion engine with a motor brake device and a valve lash adjusting mechanism

An engine braking and compensation mechanism technology, applied in engine control, engine components, machines/engines, etc., can solve the problems of valve transmission mechanism damage, insufficient opening of exhaust valves, cost of money and time, etc., and achieve reliable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

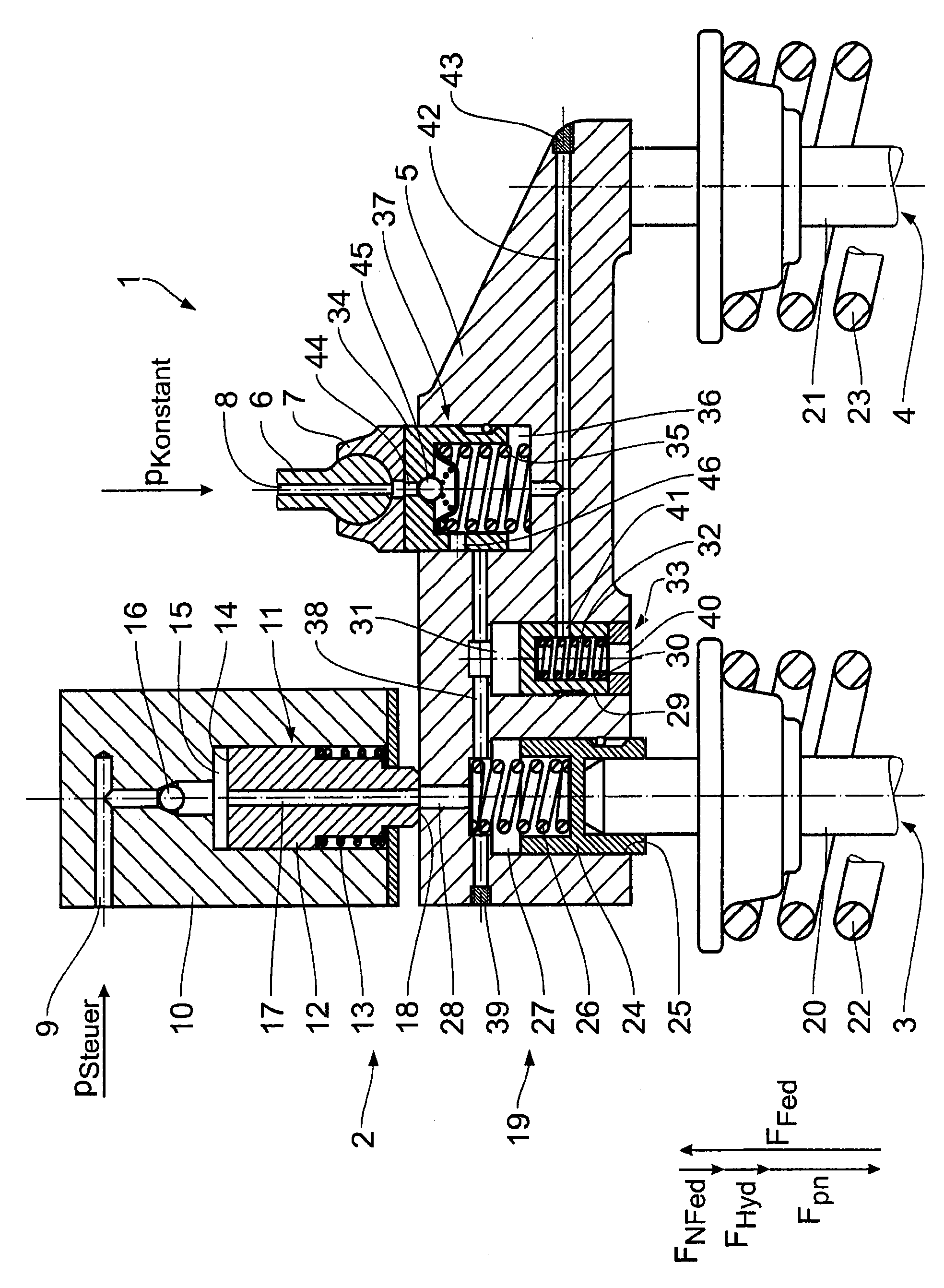

[0019] Internal combustion engine 1 has a plurality of cylinders, not shown in the drawing, which each have a combustion chamber. Air or an air-fuel mixture can be supplied to each of the combustion chambers by means of at least one intake valve. Furthermore, in the illustrated exemplary embodiment each combustion chamber has two exhaust valves 3 and 4 , by means of which exhaust gas can be discharged into the exhaust tract. The exhaust valves 3 and 4 can be mechanically controlled and actuated by means of a common valve bridge 5 . Valve bridge 5 is part of a connecting mechanism which connects exhaust valves 3 and 4 to a camshaft of internal combustion engine 1 , not shown in the drawing. Furthermore, the connecting mechanism includes a rotatably mounted valve rocker, also not shown together in the figures. The valve rocker acts on the valve bridge 5 via a partially indicated contact pin 6 . For this purpose, the contact pin 6 is equipped at its free end with a ball-and-jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com