Pre-stress cable-stayed bailey beam combined bearing system

A prestressed, cable-stayed technology, used in bridges, bridge construction, erection/assembly of bridges, etc., to achieve structural safety, reduce headroom effects, and reduce material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be clearly and completely described below in conjunction with the accompanying drawings, so that those skilled in the art can fully implement the present invention without creative work.

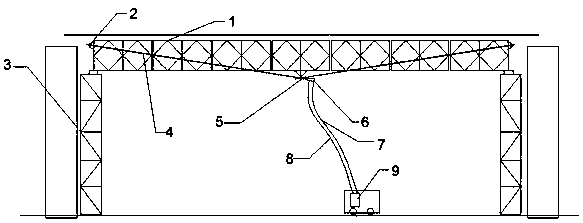

[0012] Specific embodiments of the present invention: as figure 1 As shown, a prestressed cable-stayed Bailey beam combined load-bearing system includes a Bailey beam 1 composed of Bailey frames, beam end brackets 3 placed on both sides of the Bailey beam 1 for support, and placed on The mid-span connecting support 5 of the mid-span support structure starts directly below the middle of the Bailey beam 1, and connects the two ends of the Bailey beam 1 and the mid-span connecting support 5 to generate the stay cables 4 for supporting reaction force, and anchor the prestressed oblique The anchor end 2 of the beam end of the stay cable 4 and the prestressed tensioning system for tensioning the stay cable 4, the bottom of the mid-span connection support 5 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com