Back-to-back-arranged tapered roller bearing axial pretightening device of large cantilever rotating retractable roof

A technology of tapered roller bearings and axial preload, which is applied to roofs, building components, buildings, etc., and can solve the problems of central shaft impact, low efficiency, and large friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

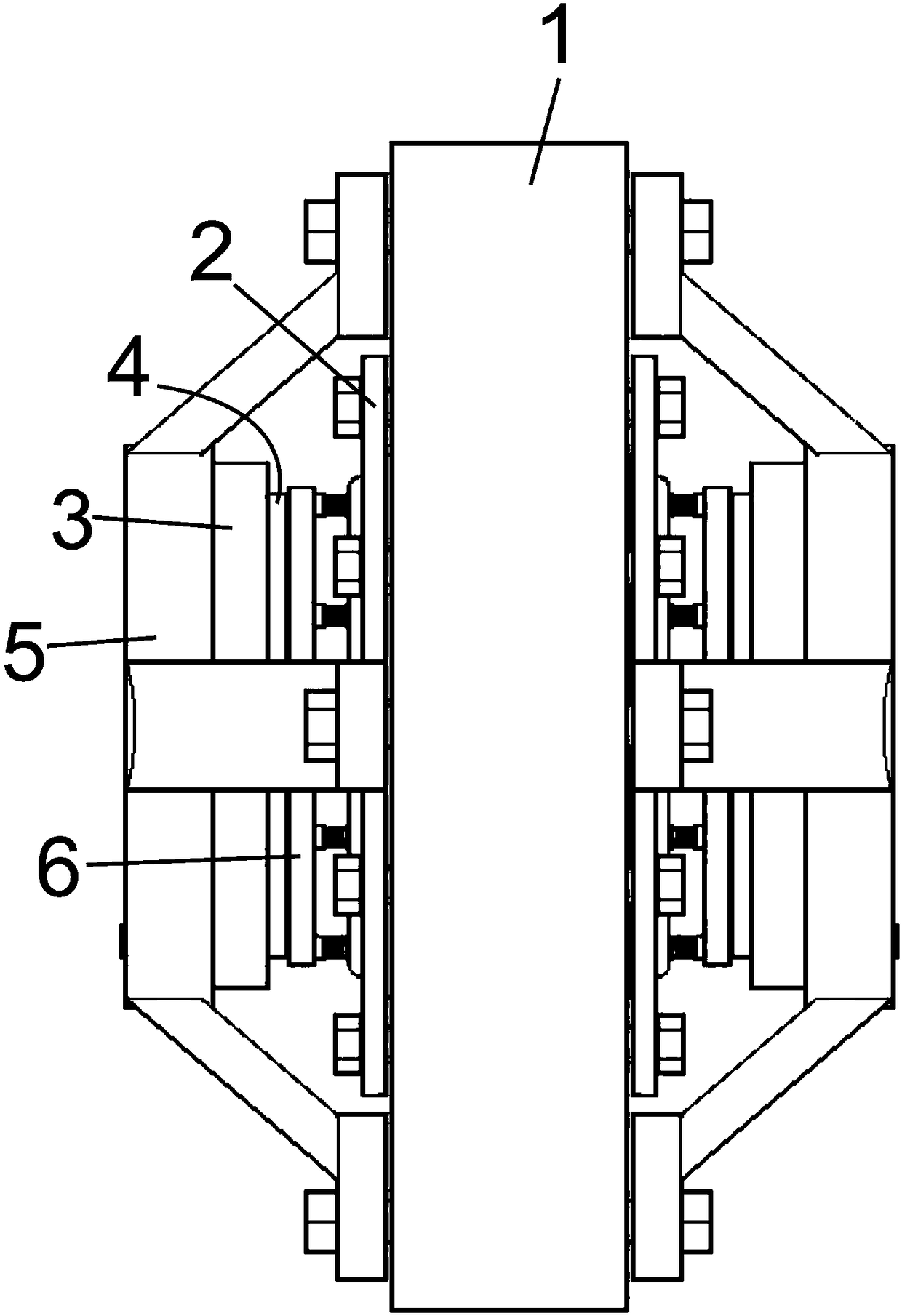

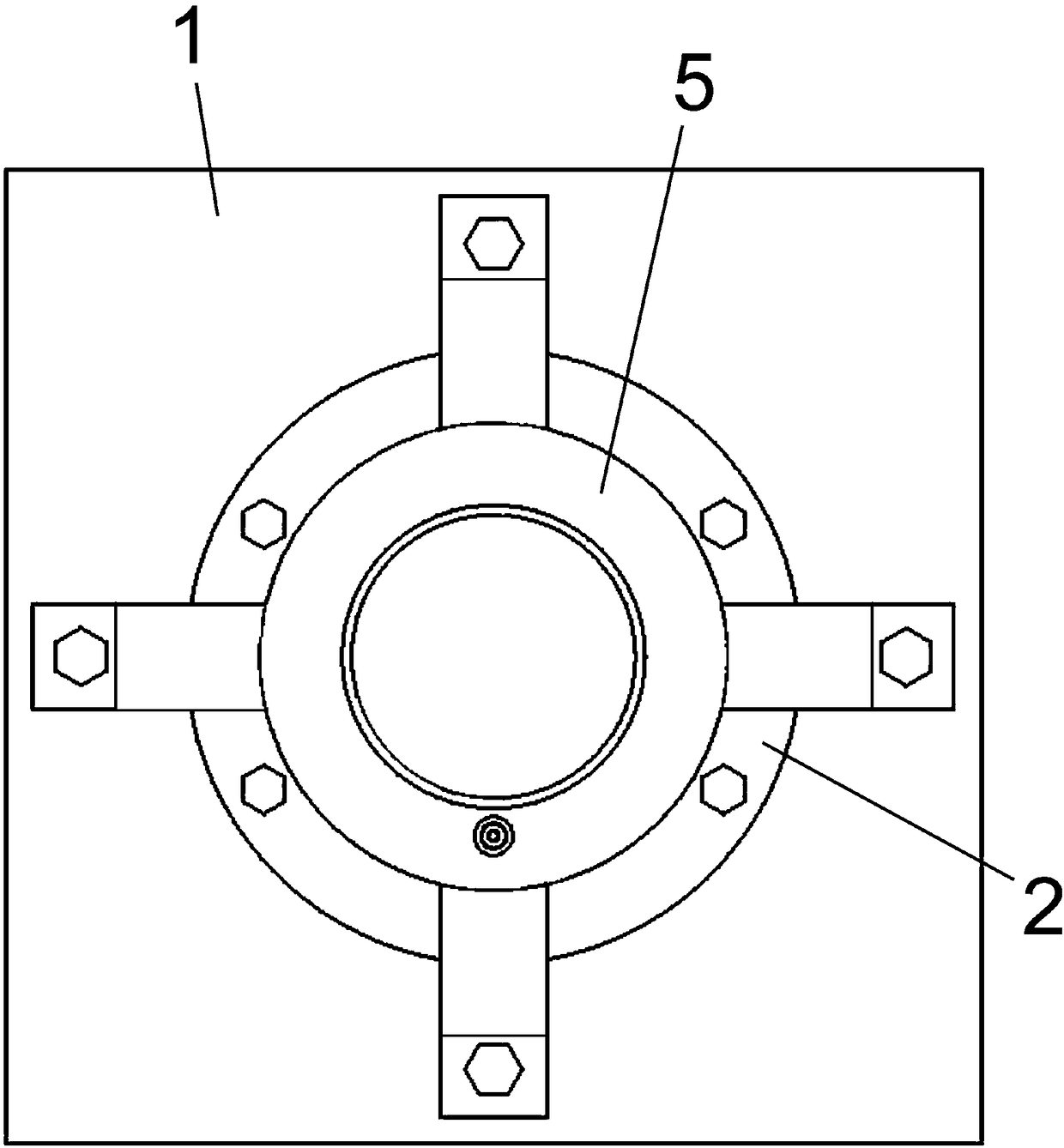

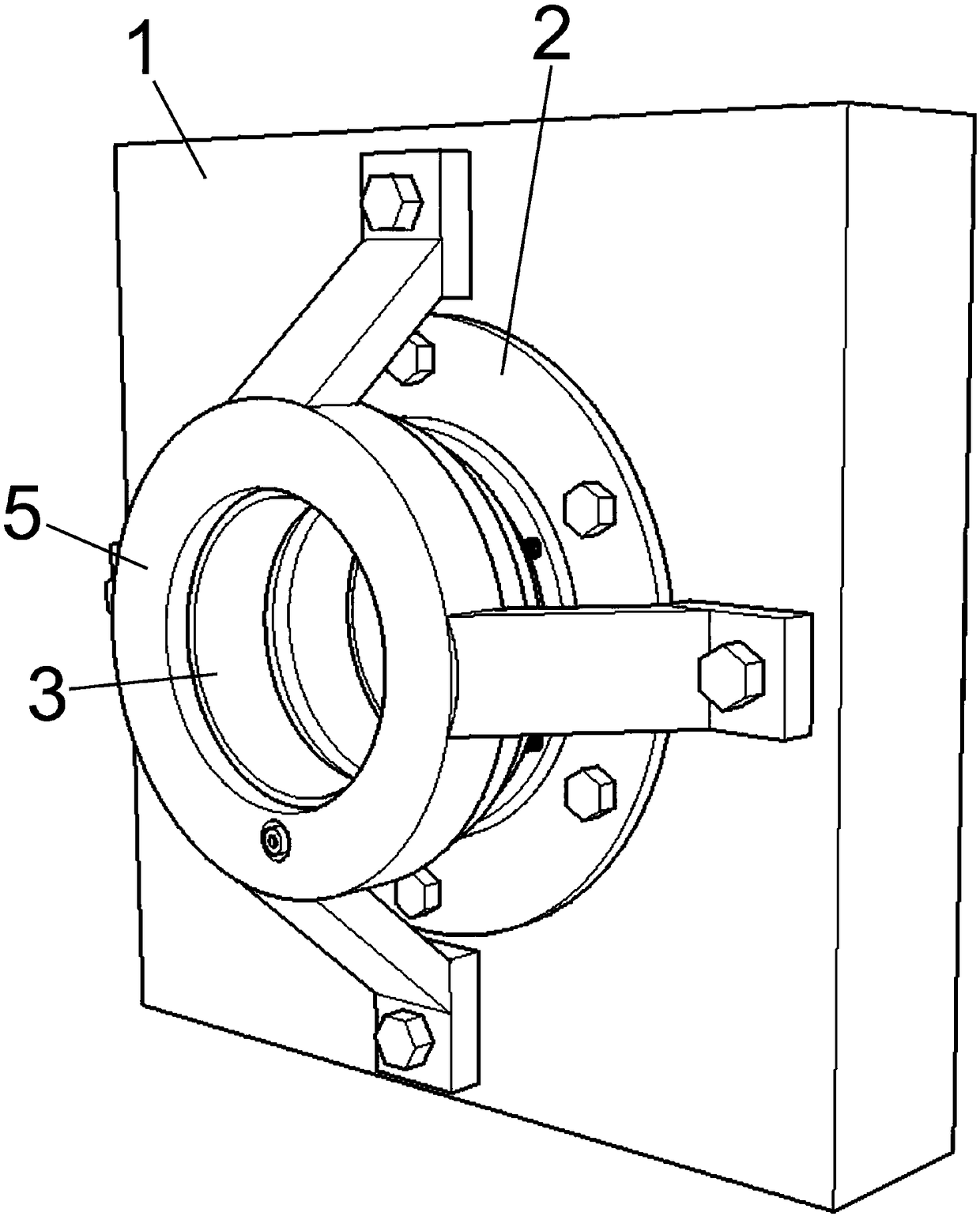

[0017] As shown in the figure, a back-to-back tapered roller bearing axial preloading device for a large cantilever rotary opening and closing roof includes a bearing seat 1, a pre-fixed part 2, a tapered roller bearing 7, and a compression ring 11, wherein the cone The roller bearing 7 is installed back to back in the bearing seat 1, and a pre-fixed part 2 is installed on both sides of the bearing seat 1. The pre-fixed part 2 is ring-shaped, and a raised compression ring is provided on the side close to the bearing seat 1. 11. The compression ring 11 bears against the outer ring of the tapered roller bearing 7, and fixes the two tapered roller bearings 7 in the bearing seat 1; on the outside of the pre-fixed part 2, a sleeve-shaped fretting spacer 6 is arranged , the front end of the micro-movement spacer 6 passes through the through hole on the pre-fixed part 2, and its front edge bears on the inner ring of the tapered roller bearing 7; an outer fixed sleeve 5 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com