Bearing of biomass particle machine

A pellet mill, biomass technology, applied in the direction of bearings, bearing components, roller bearings, etc., can solve the problems of bearing impact on use efficiency, short bearing service life, increase bearing cost, etc., to reduce use and maintenance costs, and extend bearing life. , to ensure the effect of long-term lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

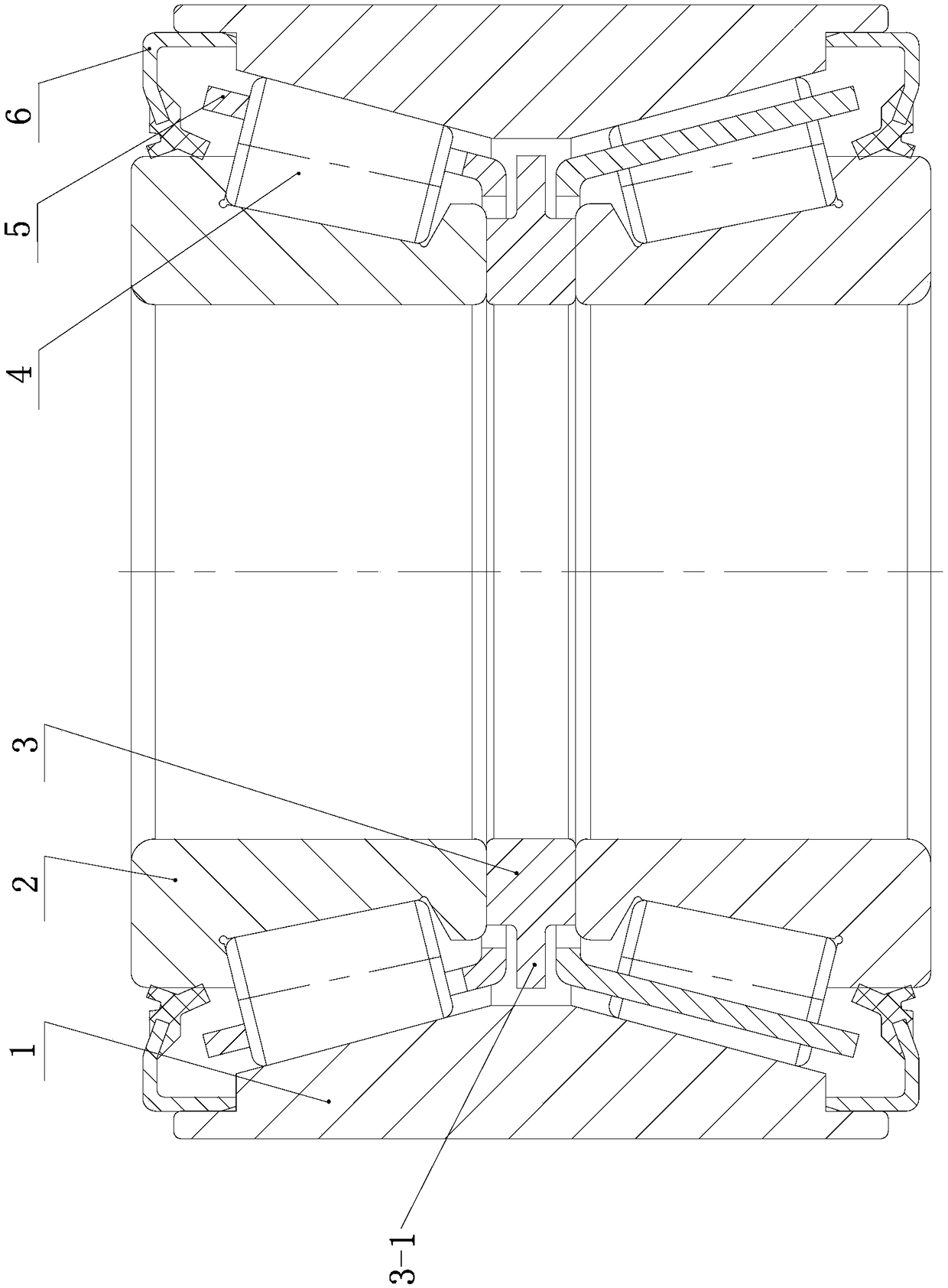

[0014] see figure 1 Explanation, 1. The bearing of the biomass pellet machine is characterized in that it includes an outer ring 1, a spacer ring 3, a roller 4, a cage 5, a sealing ring 6 and two inner rings 2; the two inner rings 2 are arranged side by side at intervals ;

[0015] A cage 5 is set between the outer ring 1 and the two inner rings 2, and rollers 4 are arranged on the cage 5, a spacer ring 3 is installed in the middle of the two inner rings 2, and a spacer 3 is installed between the outer ring 1 and the inner ring 2. sealing ring6.

[0016] The bearing is installed on the vertical shaft, and the structure adopts the form of double-row tapered rollers. The logarithmic hyperbola modification design is adopted for the roller and ring raceways. The appropriate convexity value is selected to stabilize the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com