Heat exchanger and making method thereof

A manufacturing method and heat exchanger technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of complicated manufacturing process and heavy heat exchanger, and achieve the purpose of increasing the heat dissipation area and exchanging Improved thermal efficiency and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. In addition, the technical features involved in the different embodiments of the present invention described below may be combined with each other as long as there is no conflict with each other.

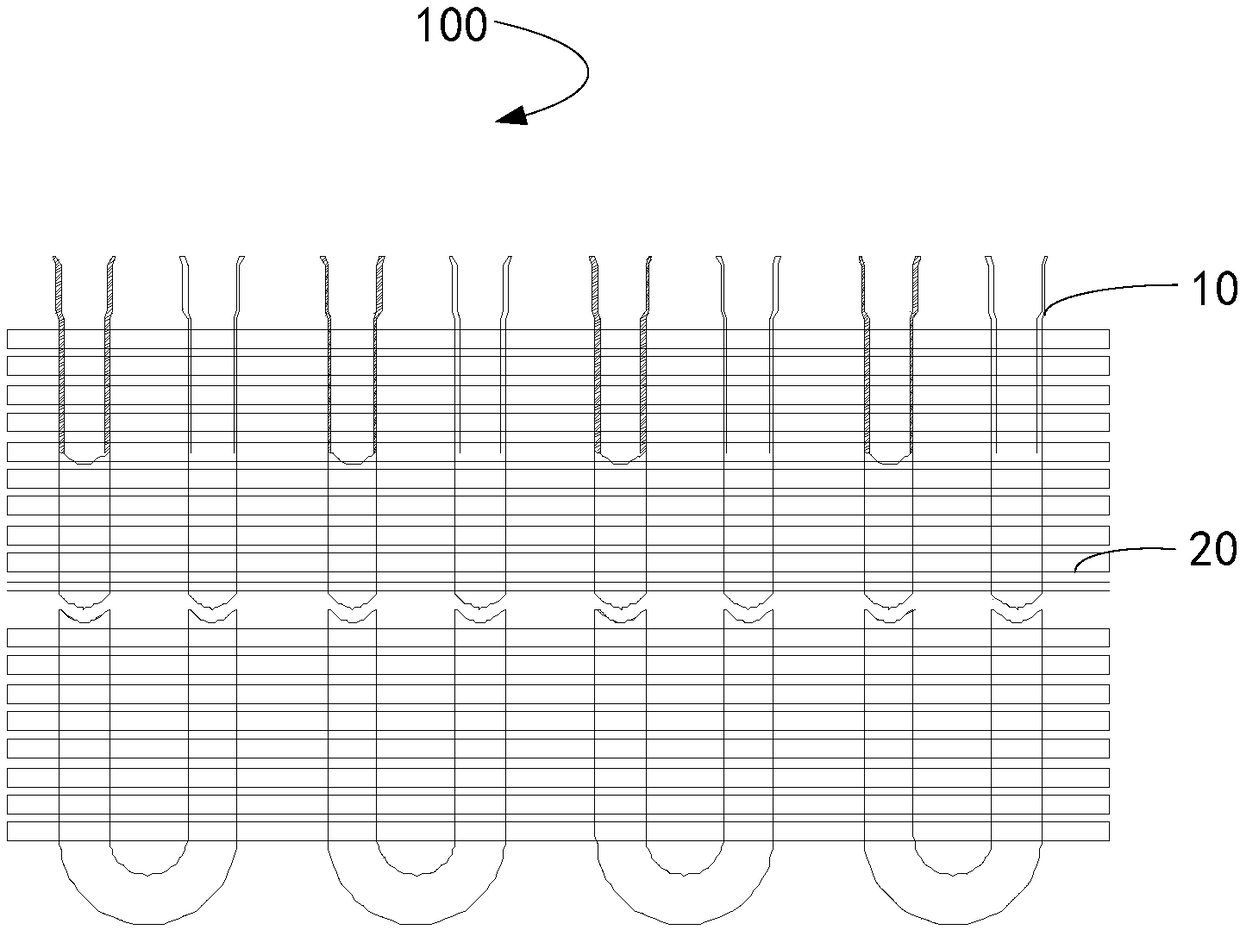

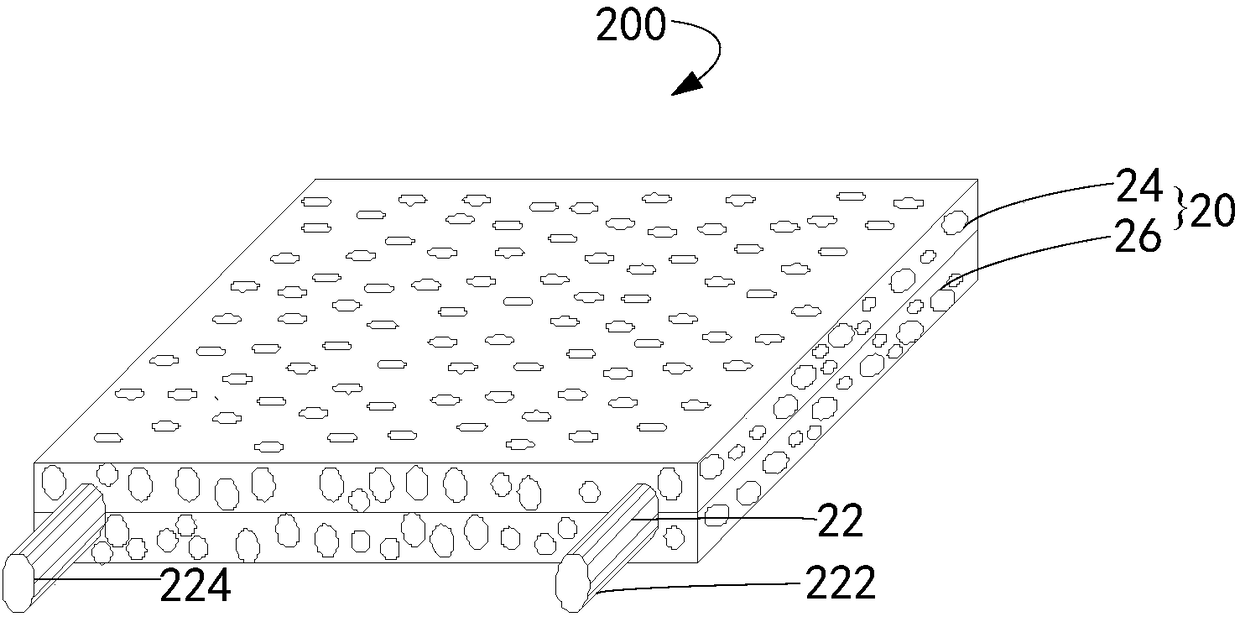

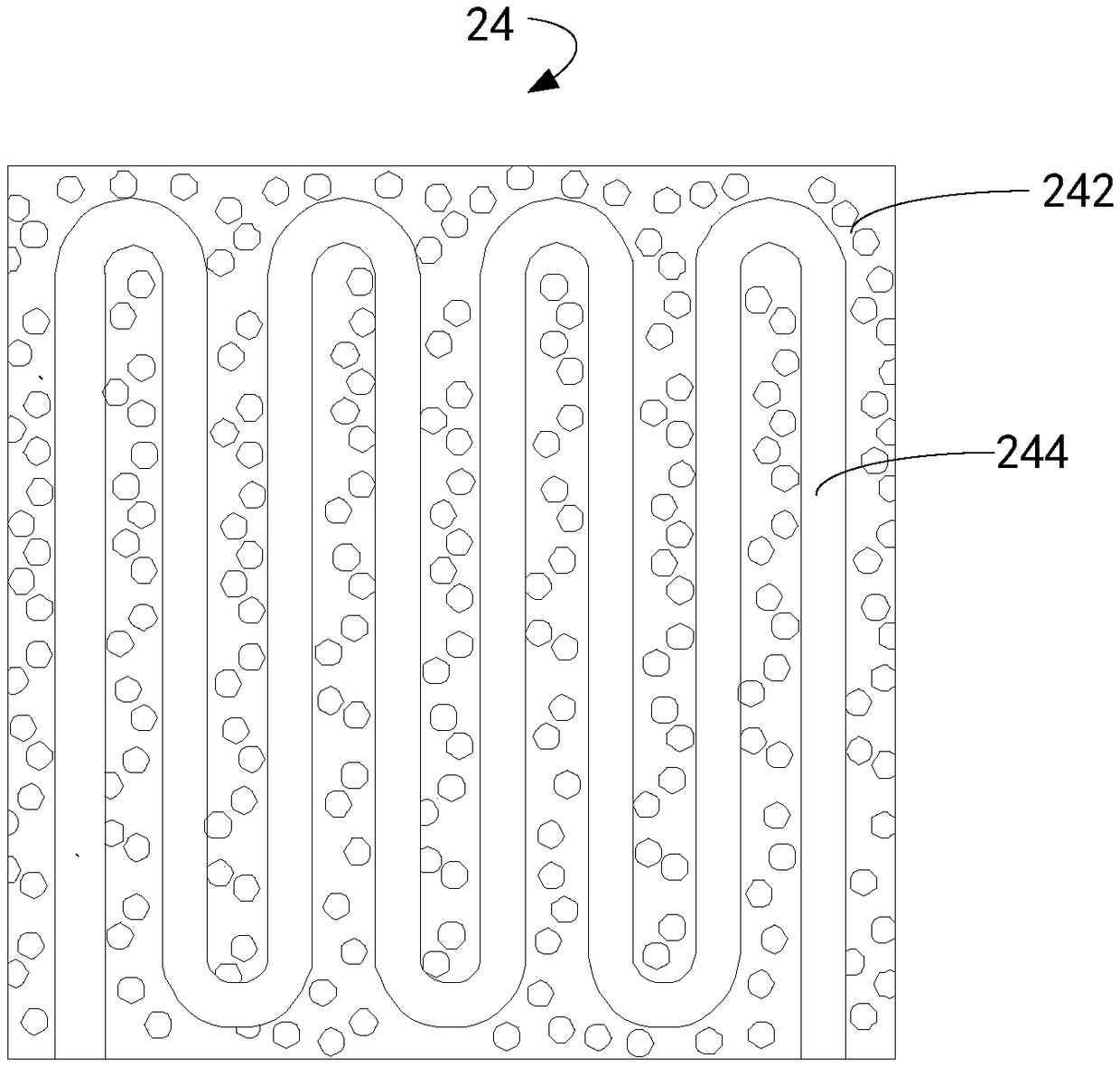

[0023] see figure 1 , The traditional heat exchanger 100 includes: a plurality of long U tubes 10 and a plurality of fins 20 connected in sequence. The fins 20 are in the shape of a sheet with a certain surface area, and may be in the shape of a square or other suitable irregular shapes (depending on the actual application environment). A plurality of fins 20 are arranged outside the long U-tube 10 at certain intervals to form a heat diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com