Heat storage method of impregnated sandstones and device thereof

A heat storage device, sand and gravel technology, applied in heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of reduced working life of concrete heat storage equipment, reduced heat transfer performance of concrete, and damage to the overall structure , to achieve the effects of easy application, improved heat transfer performance, and extended operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

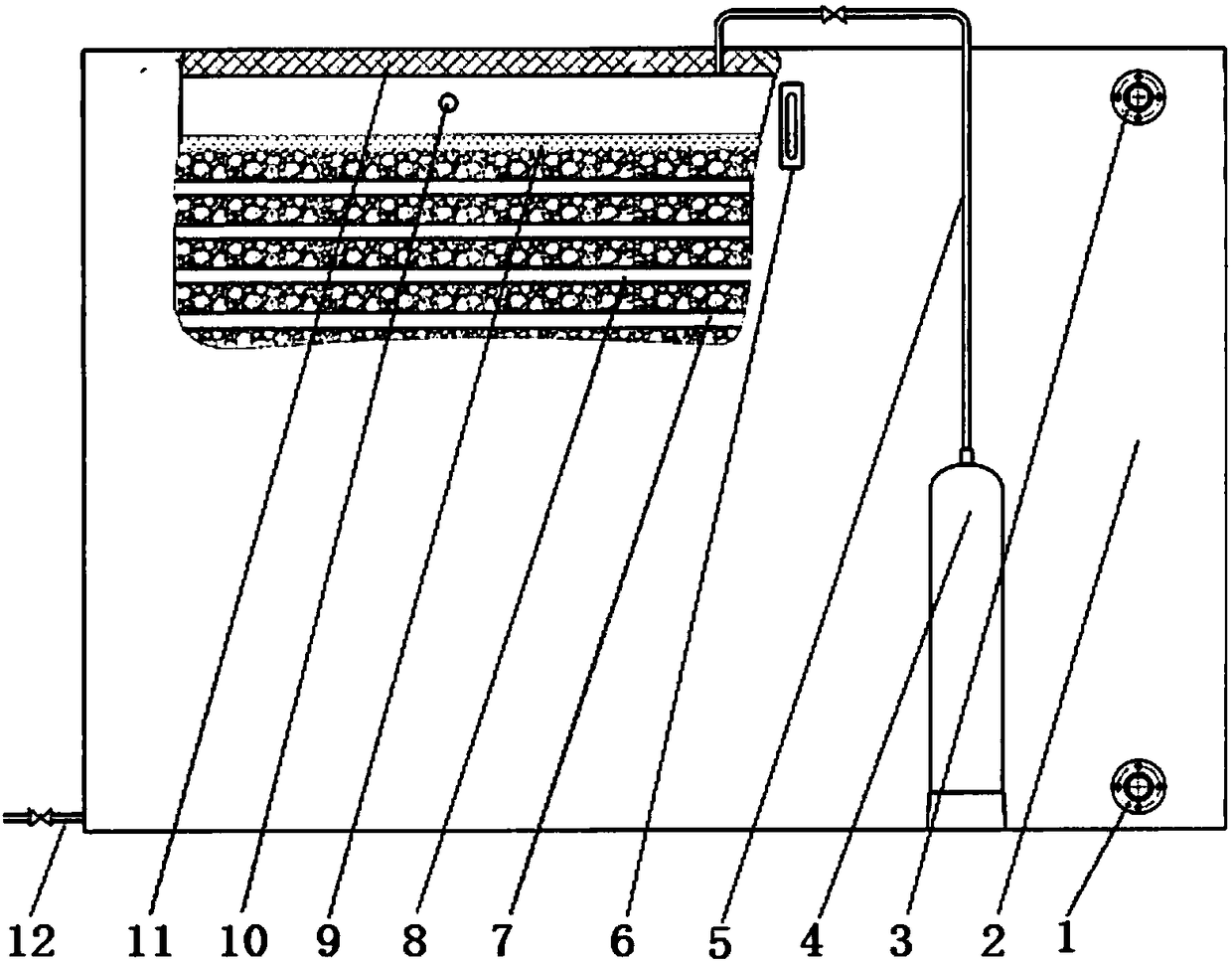

[0021] The heat storage method of impregnated sand and gravel in the present invention is as follows: a tube-rack heat exchanger is installed in the closed container of the heat storage system of the closed container, filled with sand and gravel, and then injected with an impregnating medium so that the liquid level of the impregnated medium is higher than that of the sand The fine gaps between the sand and gravel are filled in parallel to improve the heat storage performance of the sand and gravel, which can reduce the distribution density of the fluid pipeline in the heat storage device, reduce the resistance of the pipeline, reduce the power of the circulating pump, and reduce the cost of the heat storage project. come down. The heat storage method of impregnated sandstone in the present invention is divided into medium temperature heat storage and high temperature heat storage. The medium-temperature heat storage impregnation medium and heat transfer medium are both heat-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com