Method for analyzing pipeline depositing distribution

A pipeline and sediment technology, applied in the field of pipeline inspection, can solve problems such as complex operation process, threat to staff safety and health, expensive equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention, not to limit the protection scope of the present invention. Improvements and adjustments made by those skilled in the art according to the present invention in practical applications still belong to the protection scope of the present invention.

[0056] In order to better illustrate the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

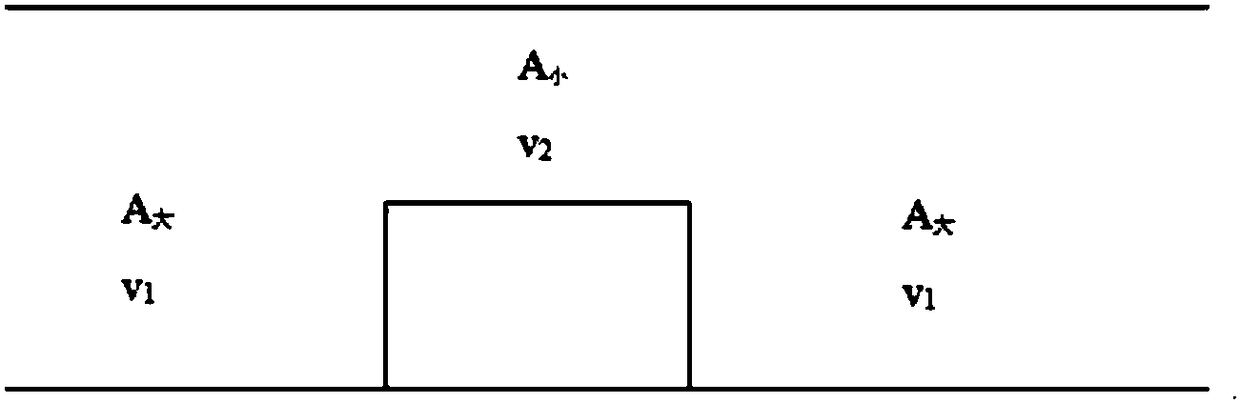

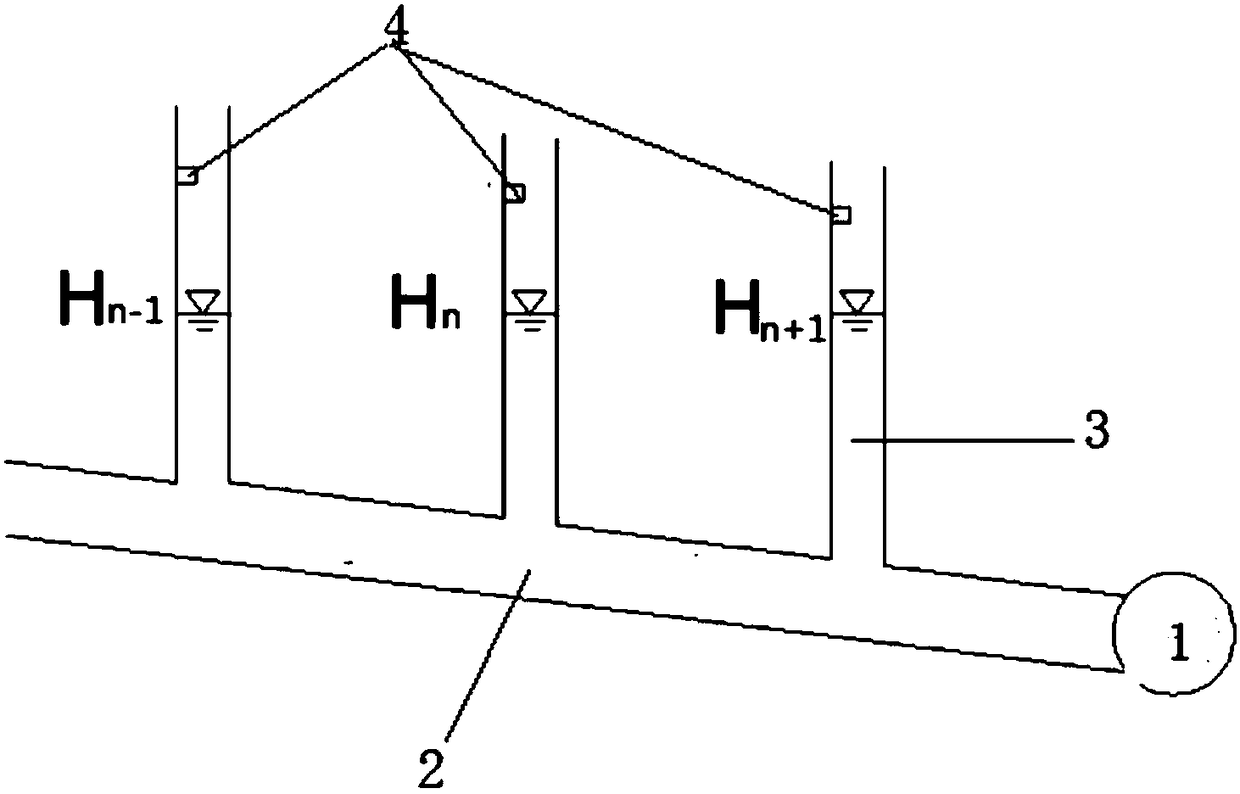

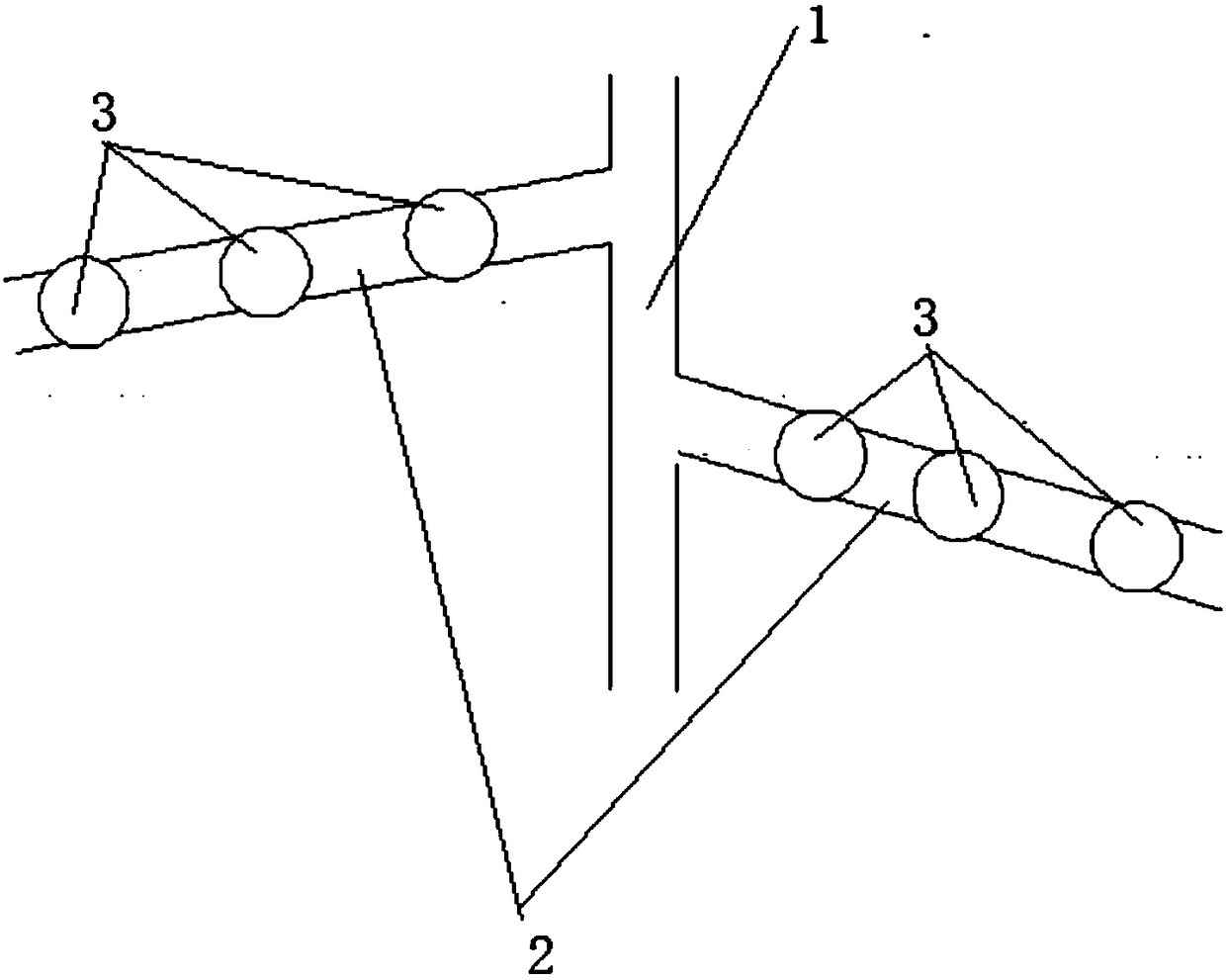

[0057] A method for analyzing the distribution of pipeline silt, comprising the steps of:

[0058] S1: Obtain the parameters of each drainage pipe, including pipe length, pipe diameter, pipe slope, and roughness coefficient; conduct pipe grouping, including grouping several pipes in the drainage system that are connected end to end, have the same pipe diameter, and have no change in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com