High-pixel LED display module

A display module and high-pixel technology, applied in identification devices, instruments, light guides, etc., can solve problems such as low yield, difficult maintenance, and difficulty in making small-pitch display screens, and achieve the effect of increasing pixels and improving pixels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

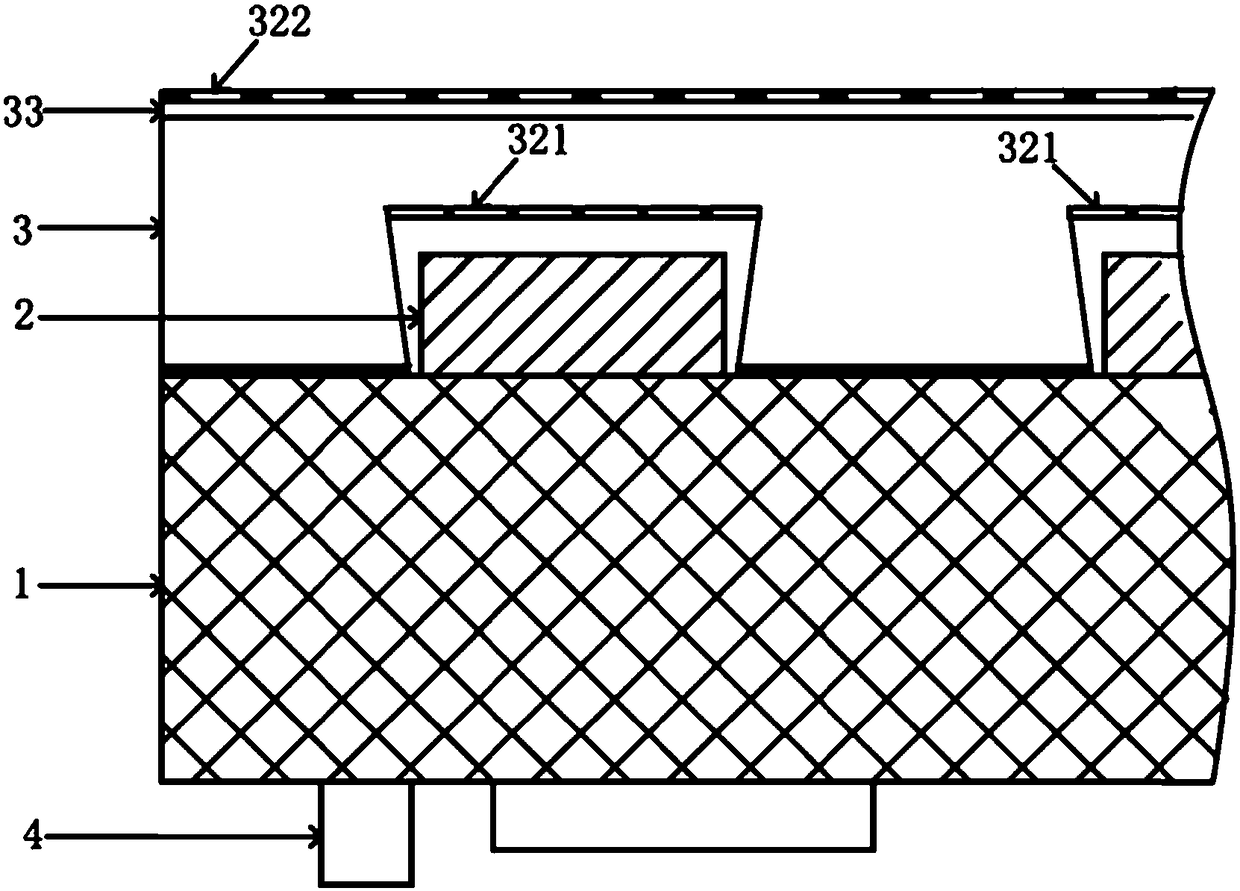

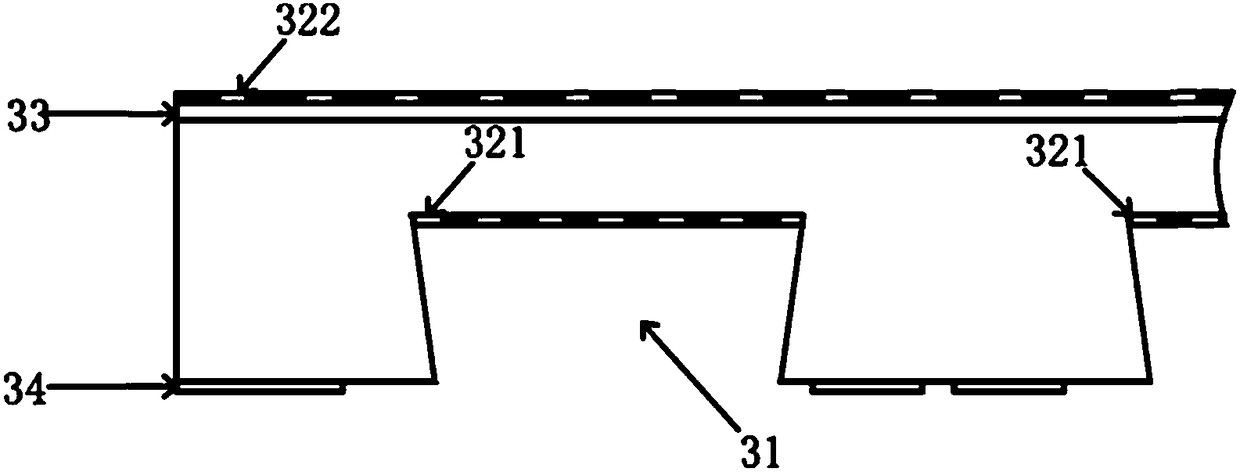

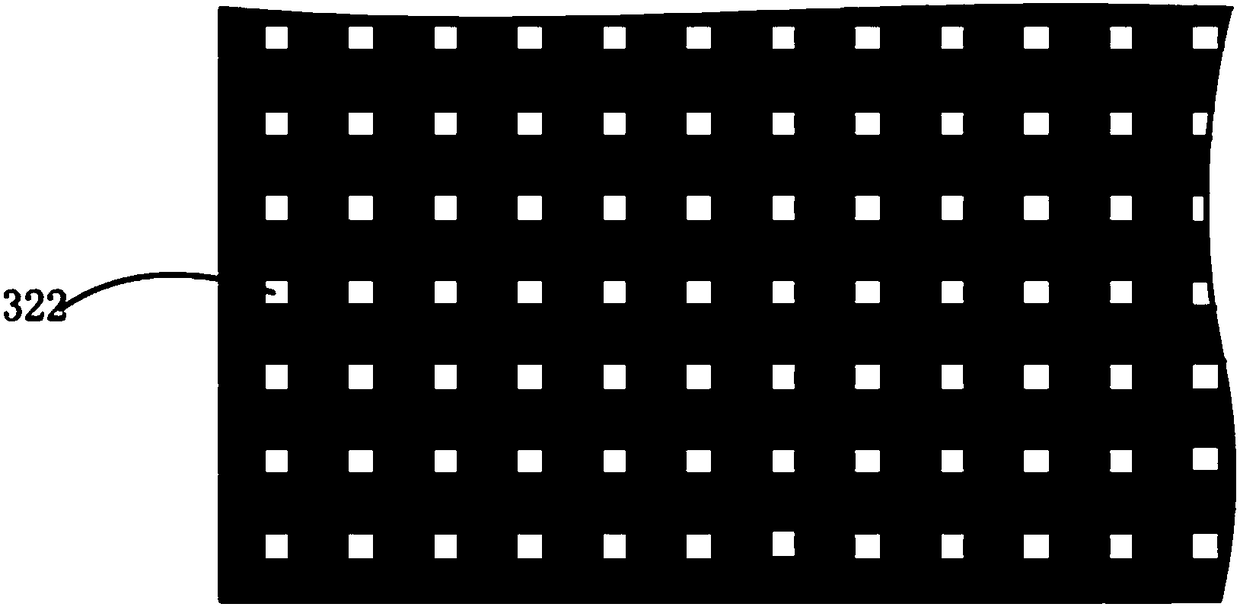

[0042] Such as figure 1 As shown, a high pixel LED display module includes a circuit substrate 1 , a light source 2 mounted on the circuit substrate 1 , a light guide layer 3 covering the circuit substrate 1 and an integrated circuit 4 mounted on the circuit substrate 1 . In this embodiment, the light source is an LED chip. The light source 2 emits light, and the light guide layer 3 guides the light emitted by the light source 2 to the outside of the light guide layer 3 . In this embodiment, the circuit substrate 1 can be composed of BT, FR4, ceramics, metal and other materials alone or in combination; the light source 2 can be a flip chip, a front chip or a vertical chip; the light guide layer 3 is a high temperature resistant material, such as acrylic, etc. .

[0043] Such as figure 1 , as shown in 2, a light source accommodating groove 31 for accommodating the light source 2 is provided on one surface of the light guide layer 3 close to the circuit substrate 2 . Such as...

Embodiment 2

[0067] The difference between the present embodiment and the first embodiment is that the light guide mechanism is a through hole arranged in the light guide layer to allow light to pass through. Light emitted by light sources of different colors passes through the through hole and is emitted to the outside of the light guide layer.

Embodiment 3

[0069] The difference between the present embodiment and the first embodiment is that the light sources all emit light of the same color. A red light filter, a green light filter and a blue light filter are respectively arranged in the different light guiding mechanisms. The red light filter, the green light filter and the blue light filter respectively absorb light of other colors in the light emitted by the light source, and only allow red light, green light and blue light to pass through.

[0070] In this embodiment, the red light filter, the green light filter and the blue light filter are respectively arranged in different light output ends.

[0071] In another embodiment, the red light filter, the green light filter and the blue light filter are respectively arranged in different lighting ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com