Manufacturing method of stereoscopic sock shoe with stiffness

A manufacturing method and three-dimensional technology, which is applied in the manufacturing field of socks and shoes, can solve the problems of pressure and friction, long manufacturing time of knitted shoes, and difficult for consumers to favor, and achieve the waterproof effect of wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

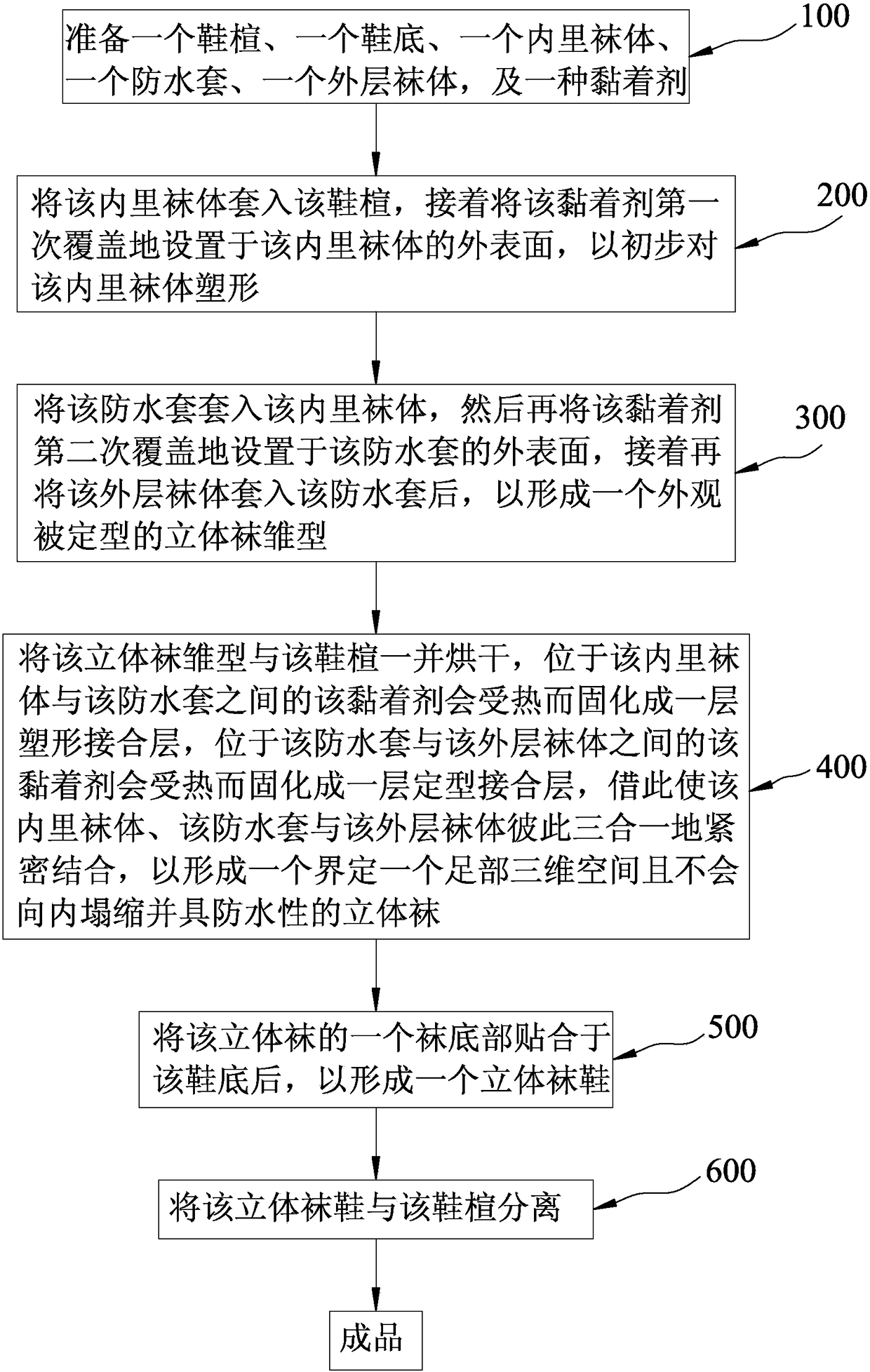

[0032] refer to figure 1 It is a flowchart of an embodiment of the manufacturing method of the stiff three-dimensional socks of the present invention, and the manufacturing method of the stiff three-dimensional socks of the present invention includes the following steps:

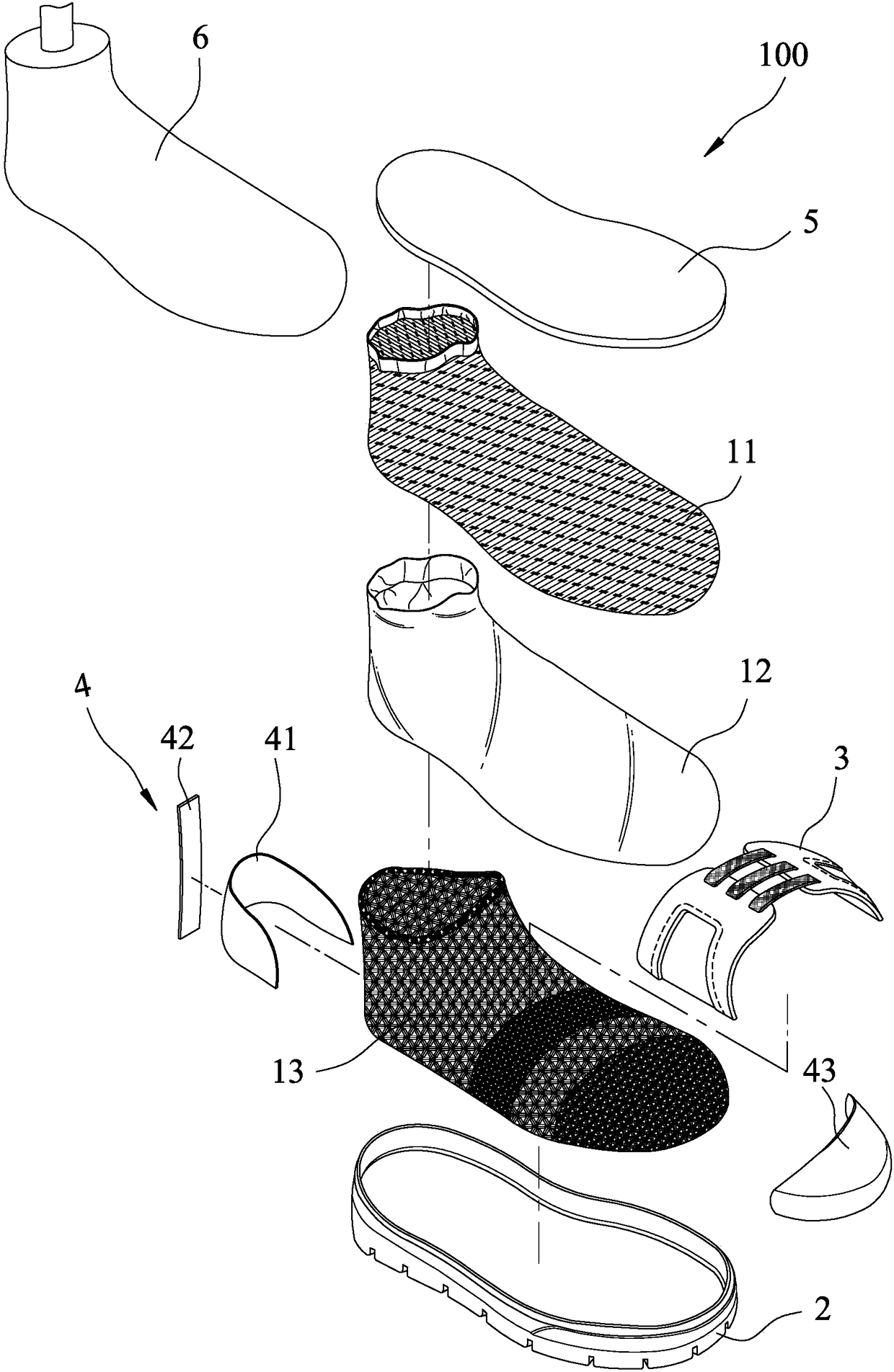

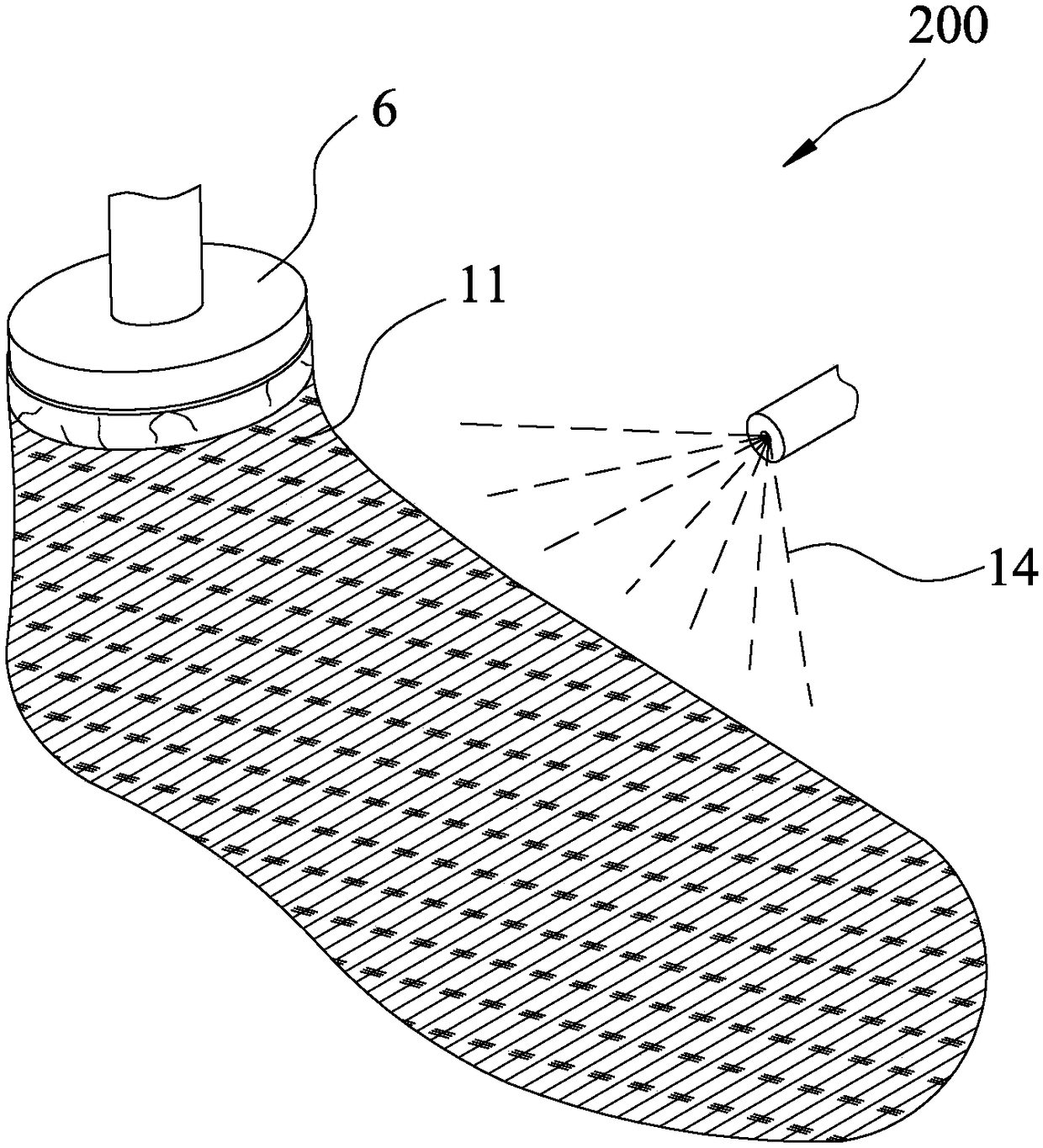

[0033] Step 1, such as figure 2 As shown, material preparation operation 100: prepare an inner sock body 11, a waterproof cover 12, an outer layer sock body 13, a kind of adhesive 14 (see image 3 ), a shoe sole 2, a tightening unit 3, a strengthening unit 4, an insole 5, and a shoe last 6.

[0034] The inner sock body 11 can be an integrally formed knit sock with a soft touch, a certain thickness and texture, but it does not need to be limited thereto, for example, it can also be made of non-woven fabric as a material and integrally formed.

[0035] The waterproof case 12 has m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com