Method for making sparkling beverage with capsule beverage machine and capsule beverage machine

A technology for foaming beverages and beverage machines, applied in beverage preparation devices, household appliances, applications, etc., can solve problems such as reducing product use experience, affecting machine stability, increasing packaging, and reducing production costs and machine energy consumption. , The stability of the machine work is guaranteed, and the effect of the production process is avoided.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

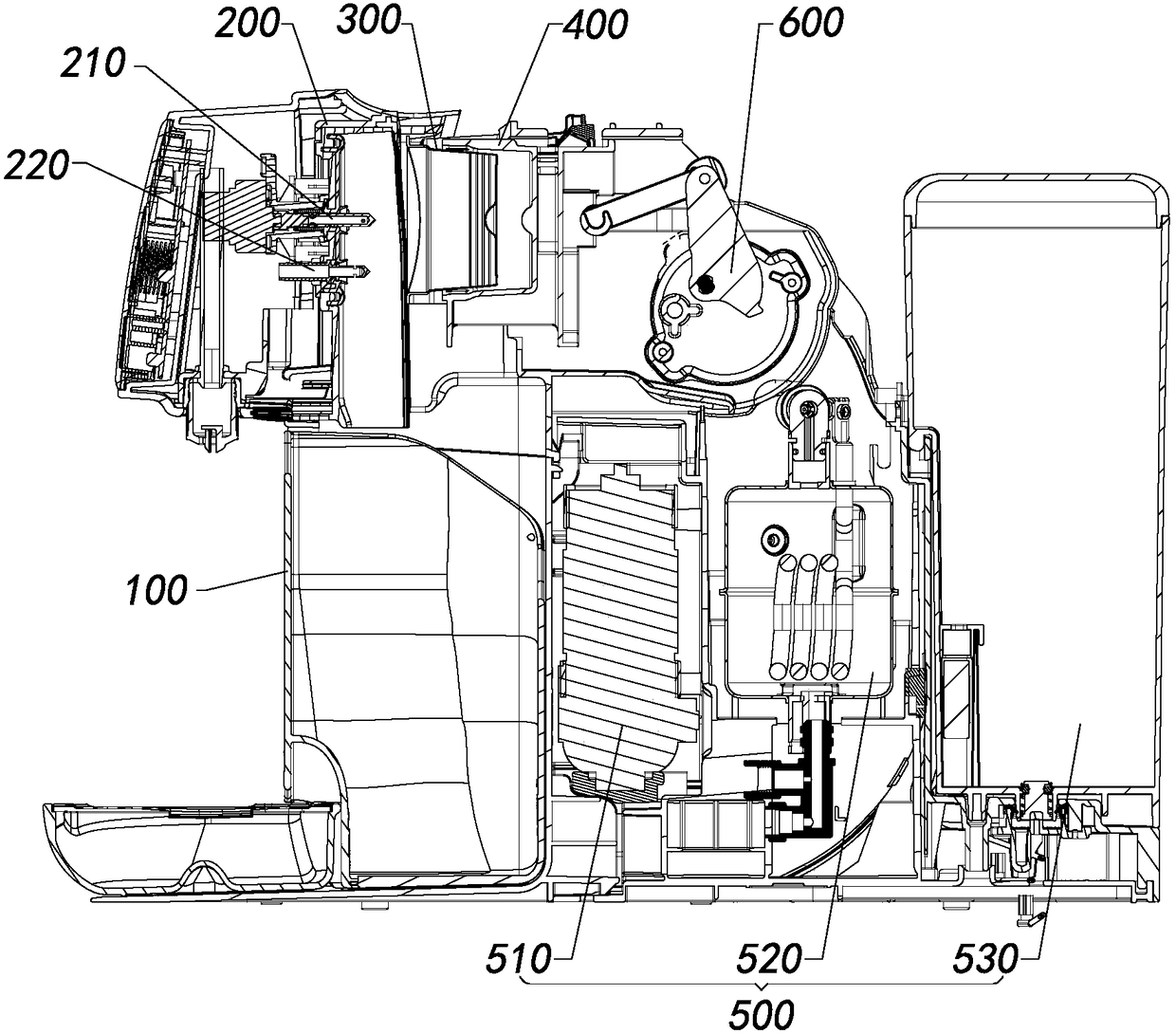

[0054] Embodiment 1 of the present invention proposes a method for producing foamed beverages with a capsule beverage machine, the capsule beverage machine includes a machine base, a brewing head with a water-inlet needle, a brewing cup for accommodating capsules, a drawing needle, a supply A liquid mechanism and an air supply mechanism, the liquid supply mechanism and the air supply mechanism are connected to the water inlet puncture needle, and the method for making a foaming beverage includes:

[0055] In the slurry dissolving stage, the liquid supply mechanism introduces a liquid flow into the capsule through the water-intake needle, and the liquid flow dissolves the powder in the capsule to form a slurry;

[0056] In the foaming stage, the gas supply mechanism introduces gas into the capsule through the water-intake needle, which makes the slurry whip and roll in the capsule to form bubbles;

[0057] In the slurry discharge stage, the liquid supply mechanism introduces li...

Embodiment 2

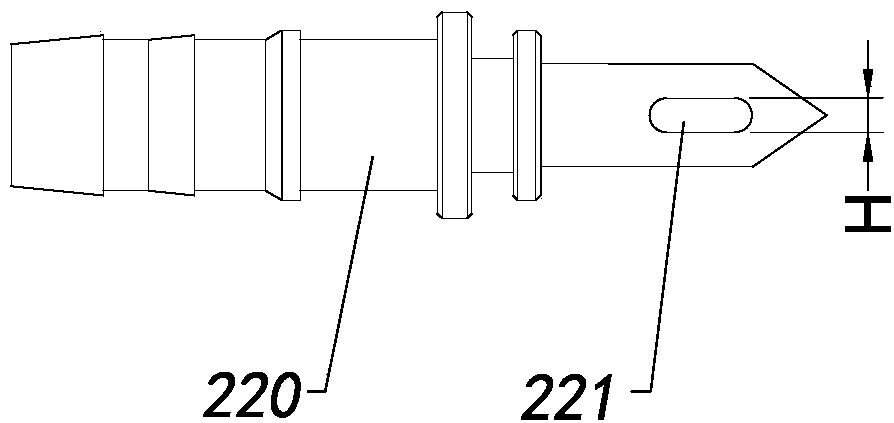

[0079] The difference between this embodiment and the first embodiment is that the capsule beverage machine also includes a driving device for driving the water-inlet puncture needle to rotate. When the water-inlet puncture needle introduces liquid or gas into the capsule, it rotates to generate a rotating jet. The beverage powder is washed by the liquid flow in the rotating jet area to mix and dissolve, which speeds up the mixing and dissolution of the liquid and the beverage powder, and the beverage powder is fully dissolved without residue, which improves the taste and nutritional value of the drink. During the rotation process, a rotating jet movement is formed, which better promotes the dissolution of the beverage powder and improves the brewing efficiency and taste of the beverage. Especially when making foaming beverages, the rotating jet can promote the rapid whipping and tumbling of the slurry in the beverage capsule, and promote the formation of air bubbles embedded i...

Embodiment 3

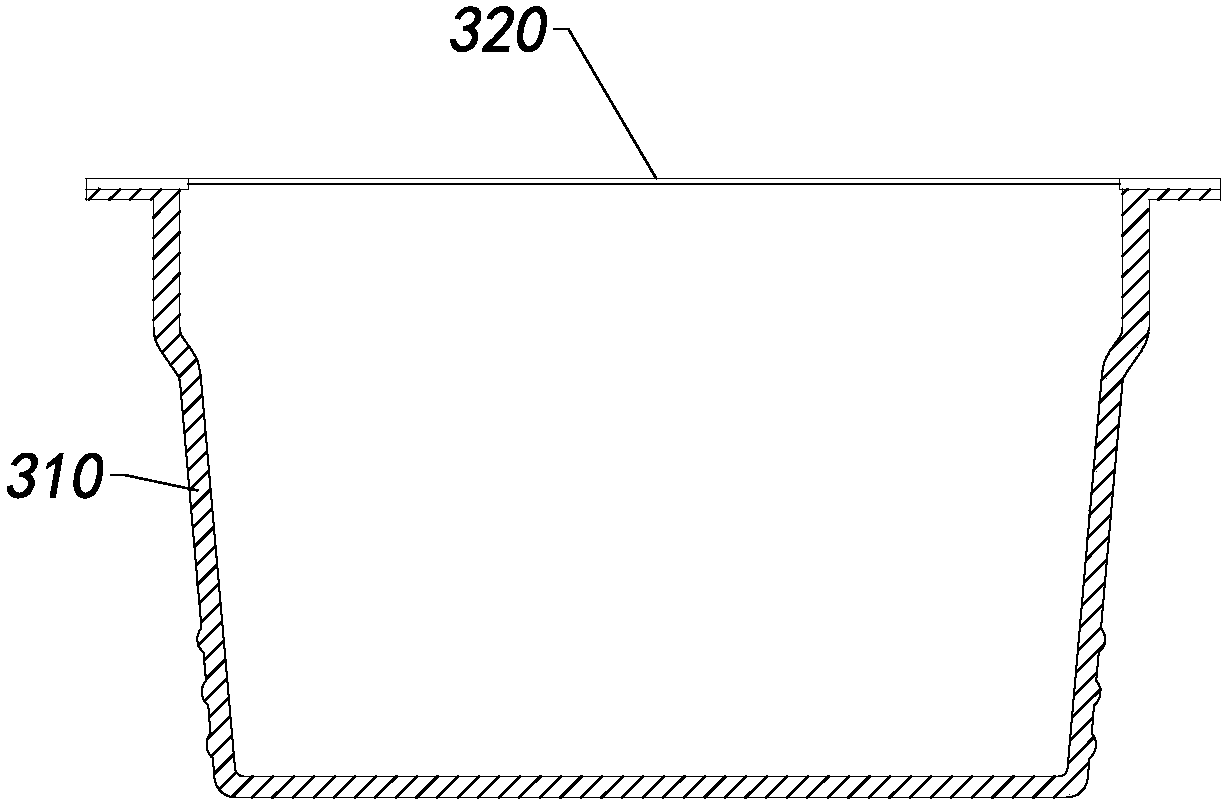

[0082] refer to Image 6 The difference between the present embodiment and the first embodiment is that the capsule beverage machine of the present embodiment is also provided with a boss 330 for reflecting liquid flow on the bottom wall of the capsule cup 310 of the capsule used, and the boss 330 is placed on the capsule The projected area on the bottom wall of the cup 310 is S1, the flow area of the injection hole is S2, 10≤S1 / S2≤20, and the upper part of the boss 330 has a reflection plane parallel to the bottom wall of the capsule cup 310. The jet introduced from the injection hole of the water-inlet puncture needle dissolves the powder to form a slurry, and the fluid pressure of the jet pushes the slurry to collide with the boss 330 on the bottom wall of the capsule cup 310 for reflection, which promotes the full diffusion of the liquid flow and increases the dissolving area to fully and evenly Dissolve the powder in the capsule, thereby reducing the requirements on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com