Reactor with thin-wall lining and production method of reactor

A reactor and lining technology, which is applied in thin-walled reactors and its manufacturing field, can solve problems such as bulging and leakage, and achieve the effects of convenient socketing, reducing the number, and increasing sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

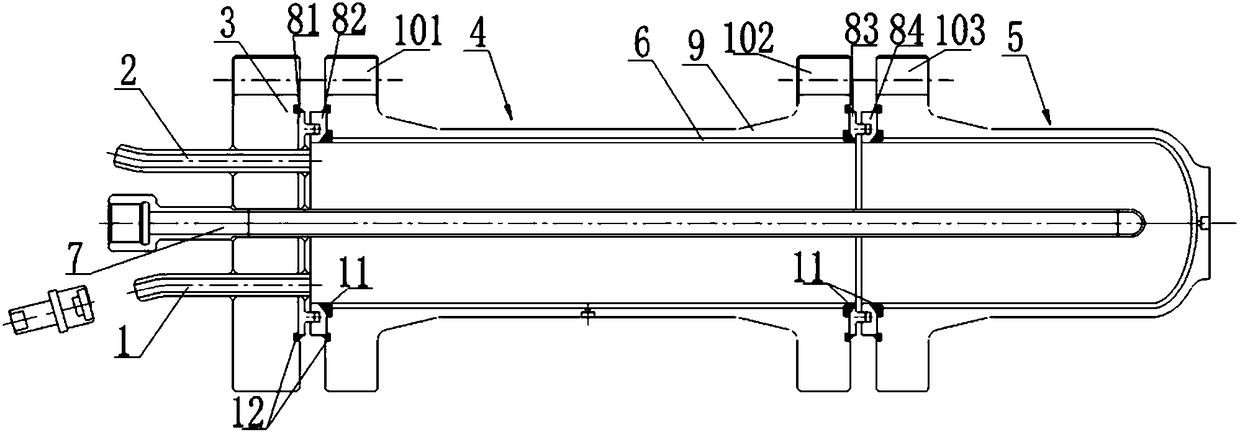

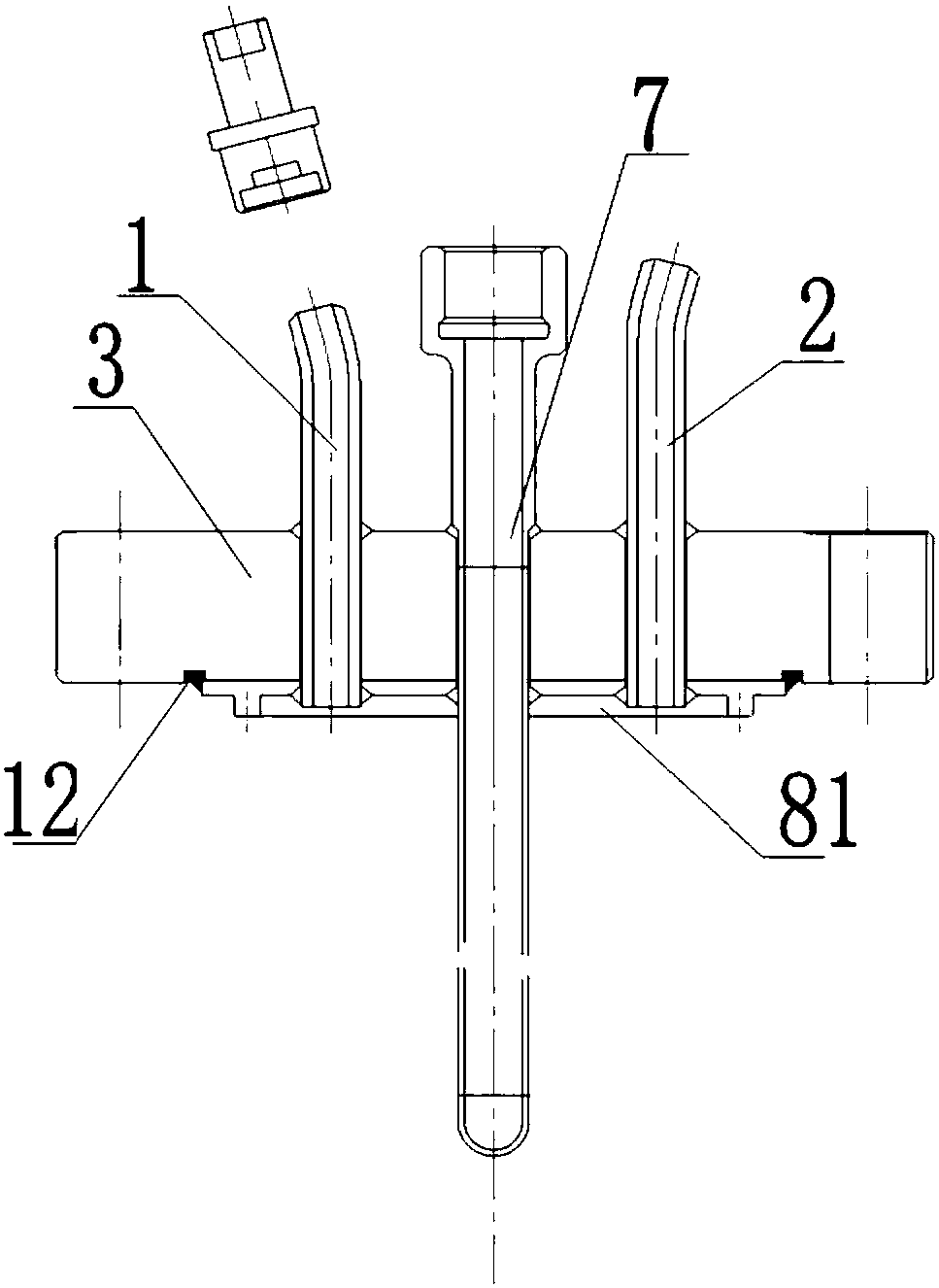

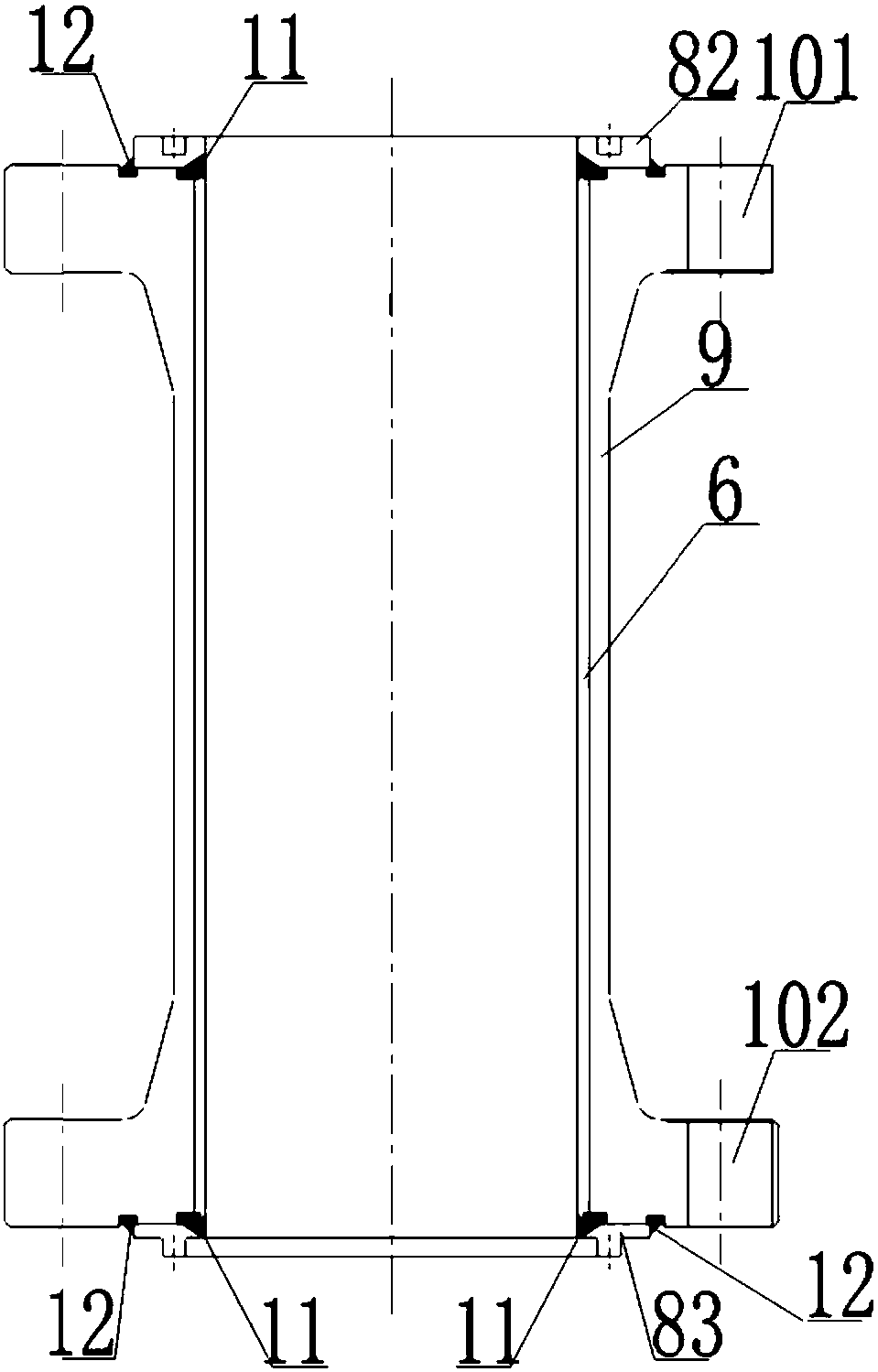

[0057] Such as Figure 1-4 As shown, a thin-walled lined reactor includes a flange cover 3, an upper shell 4 and a lower shell 5 fixedly connected in sequence, and the upper shell 4 and the lower shell 5 both include inner layers connected to each other through a heat sleeve The cylinder 6 and the outer cylinder 9, the flange cover 3 is provided with a material inlet 2, a material outlet 1 and a test insertion port 7, the inner cylinder 6 of the upper shell 4, and the inner cylinder of the lower shell 5 6. The flange cover 3 and the material inlet 2, the material outlet 1, and the test insertion port 7 on the flange cover 3 form a sealed reaction chamber. In this embodiment, the test insertion port 7 is sealed with a downward housing 5-direction extended temperature test device.

[0058] Both the inner cylinder body 6 and the outer cylinder body 9 of the lower shell 5 are composed of a straight cylinder section and a lower head. The straight section of the cylinder 9 and the...

Embodiment 2

[0072] A kind of thin-wall lining reactor of manufacturing embodiment 1, comprises the steps:

[0073] S1. Determine the set dimensions of the outer cylinder body 9 and the inner cylinder body 6 after processing, and the outer diameter of the material used is greater than the set dimensions of the outer diameter of the outer cylinder body 9 and the outer diameter of the inner cylinder body 6 , the inner diameter is smaller than the set size of the inner diameter of the outer cylinder 9 and the inner diameter of the inner cylinder 6, and the length is greater than the set size of the length of the straight section of the outer cylinder 9 and the length of the straight section of the inner cylinder 6, and the inner The length of the layer cylinder body 6 is greater than the length of the outer layer cylinder body 9, and the outer layer cylinder body 9 and the inner layer cylinder body 6 are processed;

[0074] Wherein the specific size of the outer shell 9 and the inner shell 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com