Ultrasonic cleaning method

An ultrasonic and multi-phase flow technology, applied in the field of cleaning, can solve problems such as performance degradation, surface and internal corrosion or damage of cleaning materials, and achieve the effect of avoiding direct damage or corrosion and strengthening the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

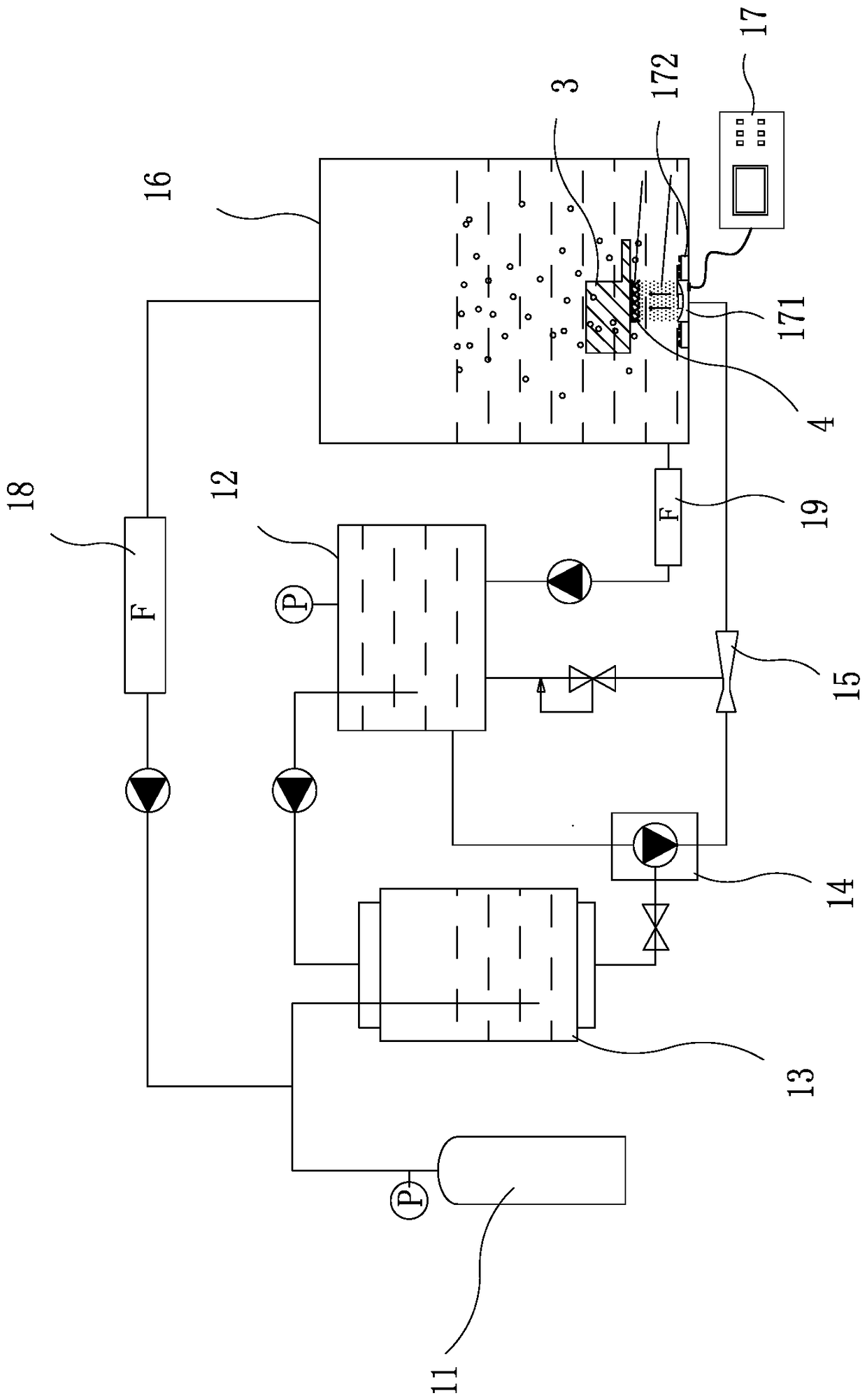

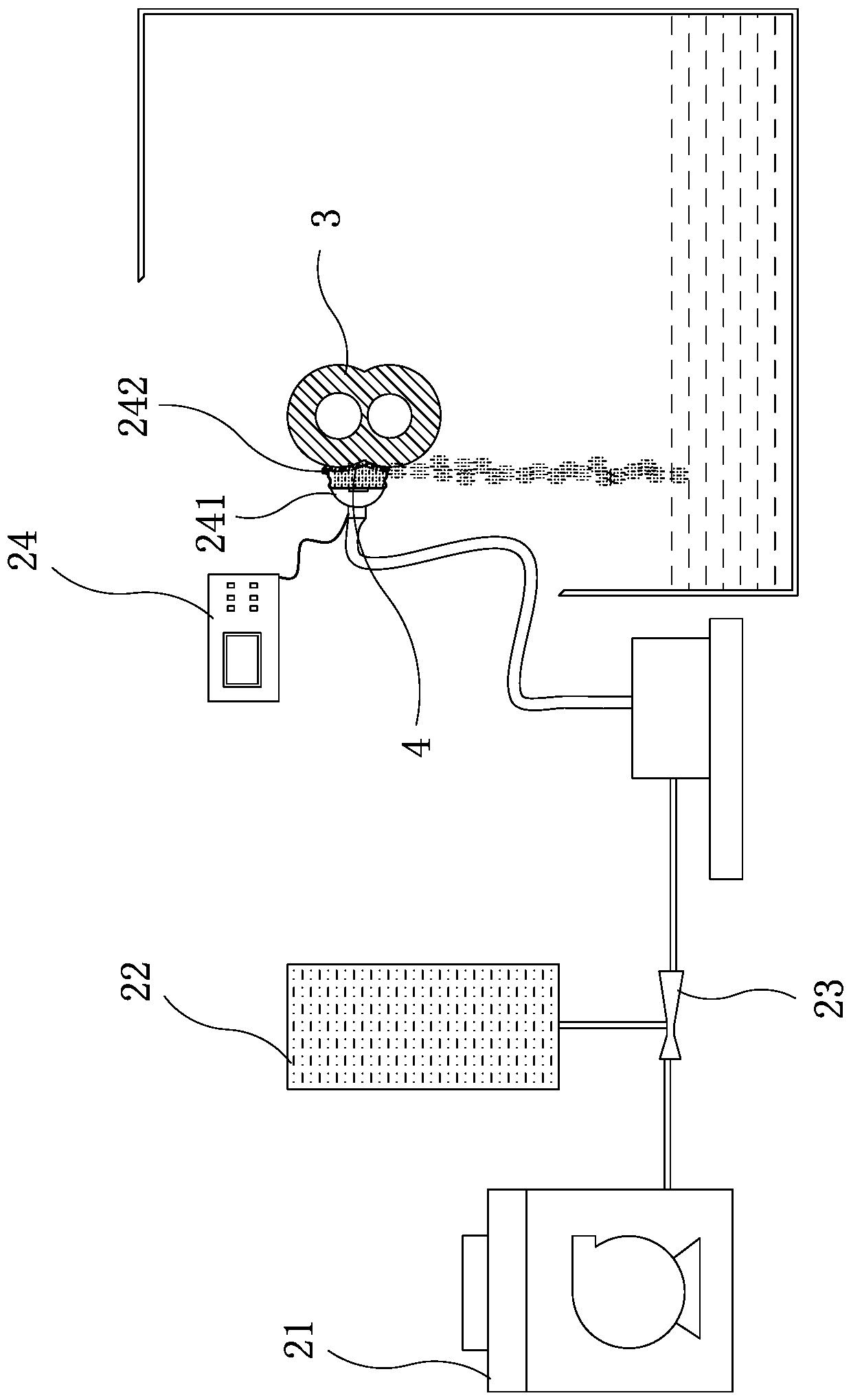

[0019] The invention discloses an ultrasonic cleaning method, which is specifically as follows:

[0020] Prepare a multiphase flow and distribute the multiphase flow on the surface of the object to be cleaned at a certain flow rate; wherein the multiphase flow includes a continuous phase and a dispersed phase, the continuous phase is liquid, and at least one of the dispersed phases is gas, and the gas is initially in the form of Microbubble;

[0021] Start the ultrasonic generator to emit ultrasonic waves, and the ultrasonic waves will reach the surface to be cleaned after propagating in the multiphase flow; adjust the ultrasonic frequency to Make the multiphase flow form a higher impedance ultrasonic retardation layer on the surface of the object to be cleaned, where, 0.1<k<0.5, P is the initial static pressure in the multiphase flow, R is the initial average radius of the gas microbubble, and ρ is The density of the continuous phase. The ultrasonic waves emitted by the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mean radius | aaaaa | aaaaa |

| Mean radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com