Assembly work station for bottom plate and fan housing of servo driver

A servo driver and fan cover technology, which is applied in assembly machines, manufacturing tools, metal processing equipment, etc., can solve problems such as difficulty in achieving mass production requirements, inability to meet manufacturers' production requirements, and irregular labor supply cycles, reducing the need for The effect of labor cost and error rate, simplifying the overall product structure, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

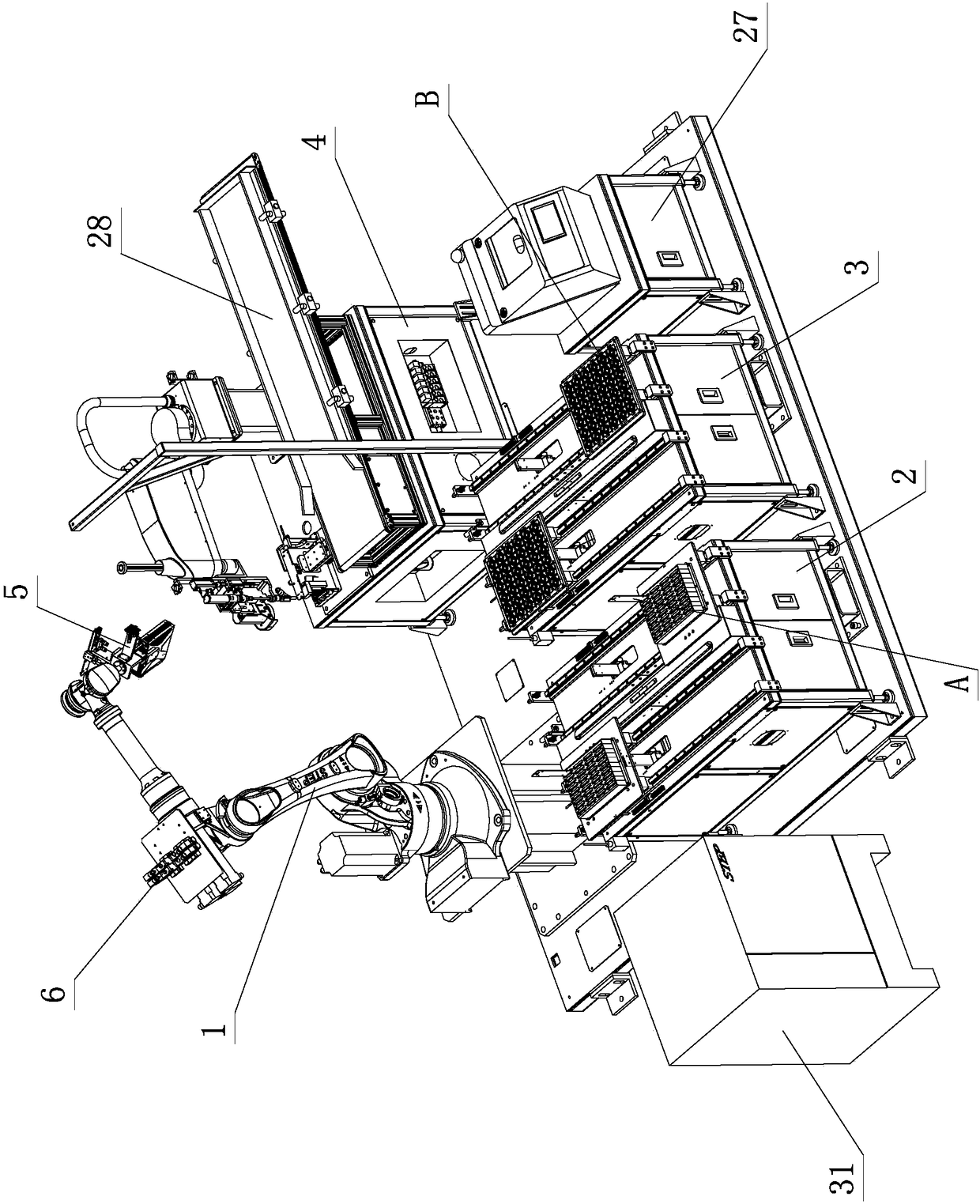

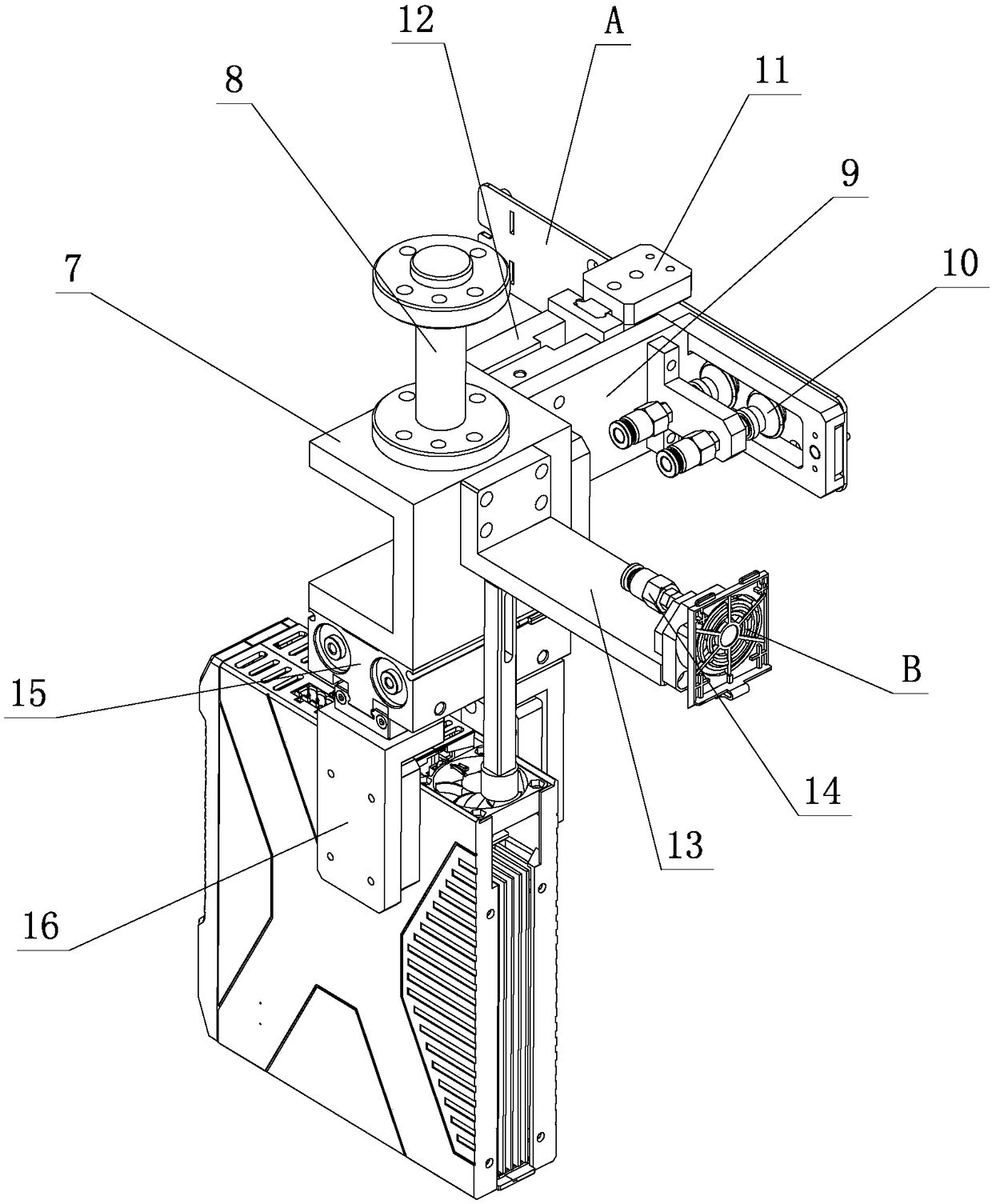

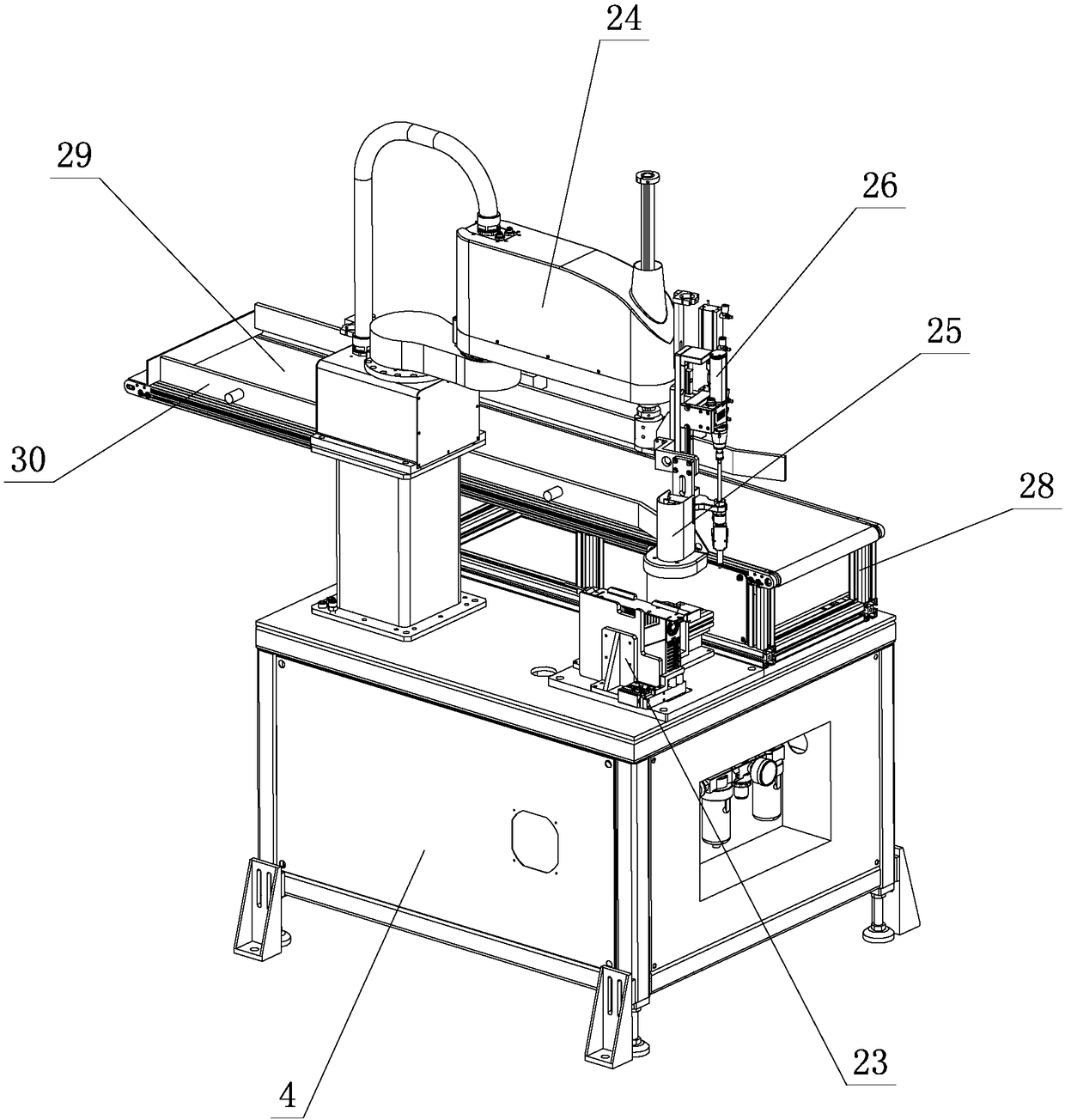

[0031] see Figure 1-Figure 6 , the assembly workstation of the servo drive base plate and the fan cover, including the base plate A of the servo drive, the fan cover B, the six-axis robot 1, the base plate storage table 2, the fan cover storage table 3 and the assembly station 4; wherein, the base plate A is stored on the bottom plate storage table 2, and the fan cover B is stored on the fan cover storage table 3; the six-axis robot 1 is provided with a loading and unloading fixture 5, and the six-axis robot 1 is separated from the bottom plate through the loading and unloading fixture 5. The bottom plate A and the fan cover B are clamped on the storage table 2 and the fan cover storage table 3, and transported to the assembly station 4, and the assembly station 4 assembles the bottom plate A and the fan cover B to form an assembly .

[0032] Further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com