Injection molding equipment for remote control

An injection molding equipment and remote control technology, which is applied in the field of remote intelligent control, can solve problems such as inability to realize data storage space and background management, inability to flexibly realize networked remote control, and inability to automatically adjust data, so as to improve network security level and prevent Viruses and hacking, effect of solving internet problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is a detailed description of the implementation cases of the present invention. This case is implemented on the premise of the technical solution of the invention, and detailed implementation schemes and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following examples.

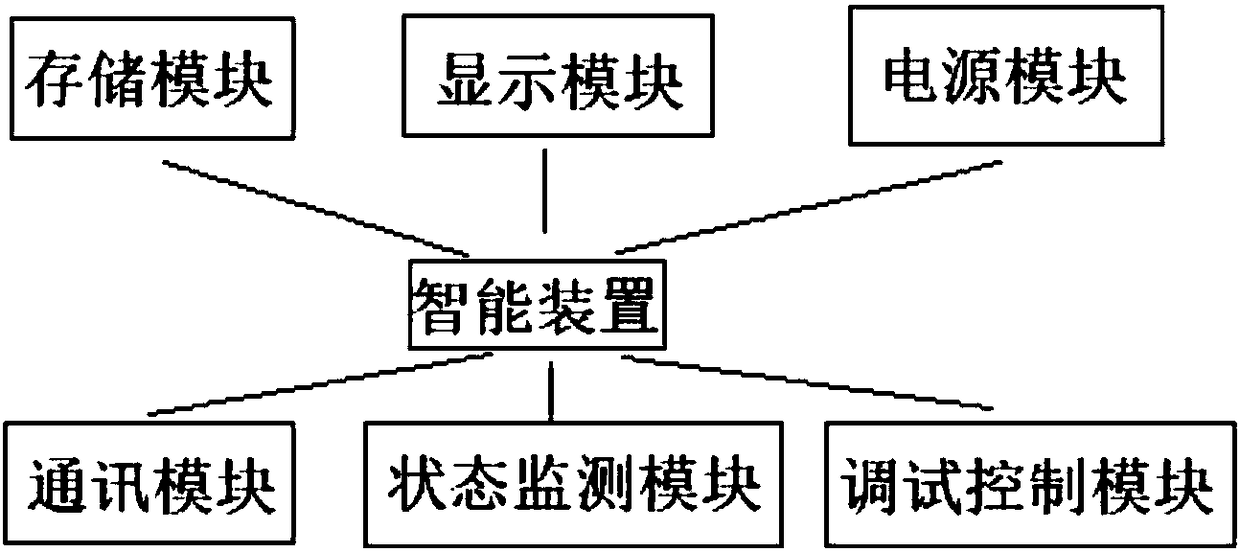

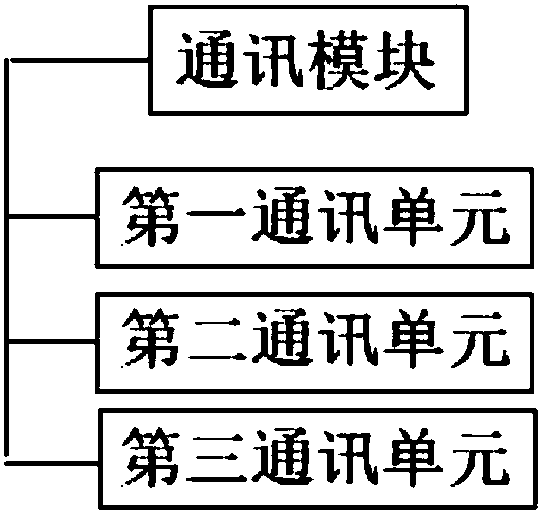

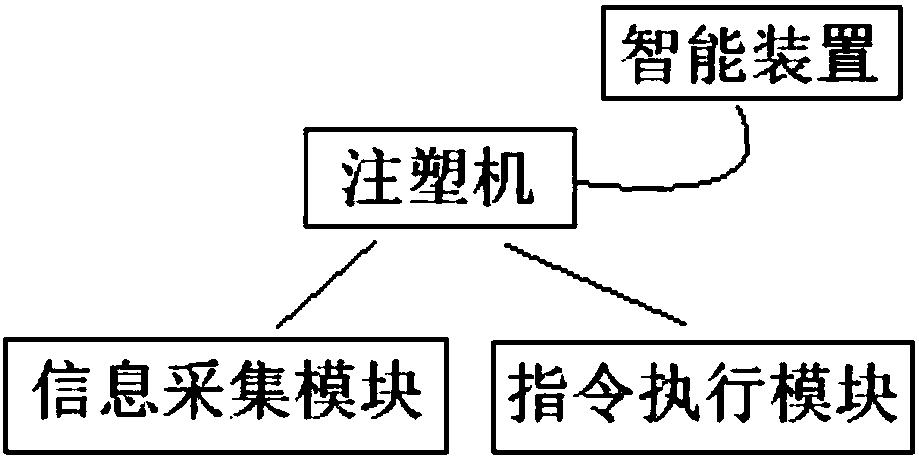

[0029] Such as figure 1 As shown, an intelligent device for remote control of injection molding equipment according to the present invention, the intelligent device includes a communication module, a status monitoring module, a debugging control module and a storage module. The communication module is used for connecting with injection molding equipment, with a mobile terminal, and with a remote service center. The state monitoring module is used to summarize and analyze various state information from injection molding equipment, including raw material quantity, raw material temperature, injection time, injection speed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com