Feed grade calcium phosphate salt and preparation method thereof

A calcium phosphate, feed-grade technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of high total production cost, rising production cost, difficulty in maintaining simple reproduction, etc., and achieve good defluorination Effect, reduced production demand, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

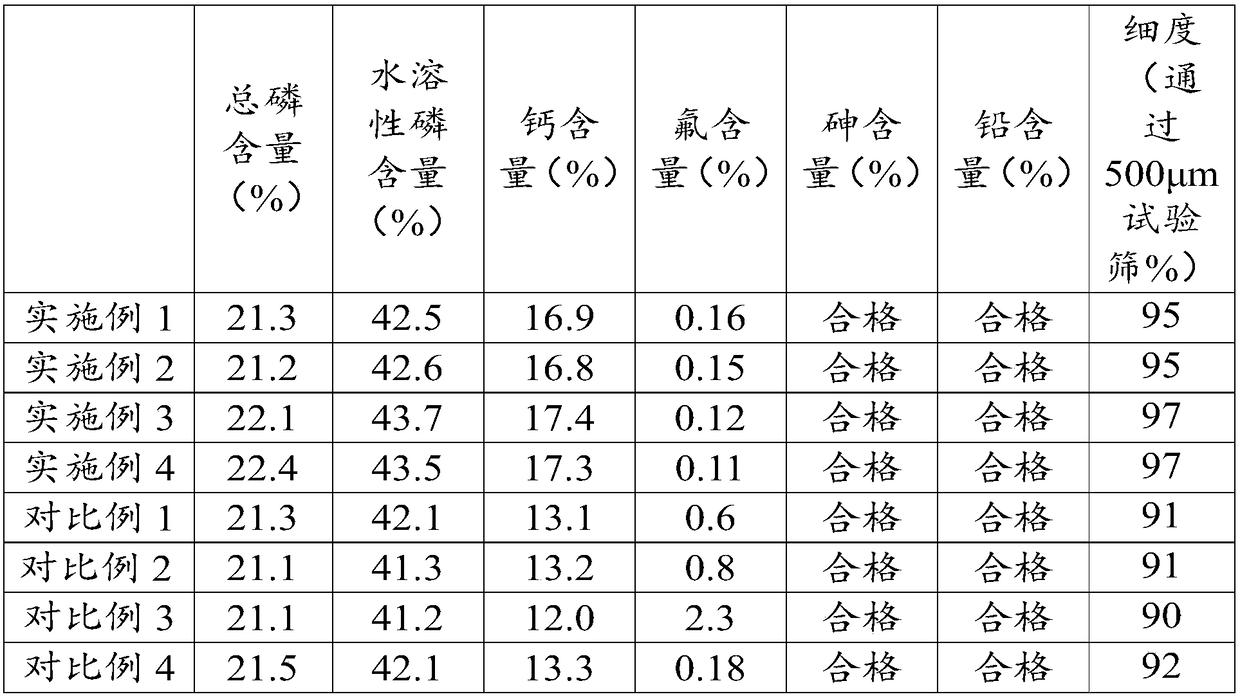

Examples

preparation example Construction

[0023] A kind of preparation method of feed grade calcium phosphate salt provided by the embodiment of the present invention comprises:

[0024] Phosphate rock is selected. In the present invention, medium and low-quality phosphate rock ore can be selected as raw material, and impurities such as magnesium, iron, and aluminum in the phosphor rock are removed by flotation, and the quality of feed-grade calcium phosphate is greatly improved. Before the reaction, crush the phosphate rock to 100-120 mesh, so that the phosphate rock and phosphoric acid can fully react and speed up the reaction rate. And crushing the phosphate rock is beneficial to subsequent impurity removal.

[0025] After mixing the phosphate rock and phosphoric acid evenly, react at 90-99°C until the pH value is 4-6. Under this condition, most of the phosphoric acid in the reaction system participated in the reaction. Preferably, the mass ratio of phosphoric acid and phosphate rock is 1-2:1, which ensures that ...

Embodiment 1

[0034] The present embodiment provides a feed grade calcium phosphate salt, which is mainly made by the following steps:

[0035] Select phosphate rock and crush it to 100 mesh.

[0036] Phosphoric acid and phosphate rock are mixed according to the material ratio of 1:1, and reacted at 90°C until the pH value is 4. Add a defluorinating agent, mix well and continue to react under this condition for 1h. Then add zeolite molecular sieves and react at 70° C. for 3 hours. After the reaction, it was filtered, and the obtained filtrate was dried at 70° C. to obtain solid powder of calcium phosphate salt.

[0037] The calcium phosphate salt solid powder and methanol are mixed and washed at a volume ratio of 1:2, and the calcium phosphate salt product and washing liquid are obtained after solid-liquid separation. The calcium phosphate product is distilled to recover methanol to obtain a feed-grade calcium phosphate product, and the washing liquid is distilled to recover methanol to ...

Embodiment 2

[0039] The present embodiment provides a feed grade calcium phosphate salt, which is mainly made by the following steps:

[0040] Select phosphate rock and crush it to 90 mesh.

[0041] Mix phosphoric acid and phosphate rock at a material ratio of 2:1, and react at 99°C until the pH value is 6. Add a defluorinating agent, mix well and continue to react under this condition for 2h. Then add zeolite molecular sieves and react at 80° C. for 4 hours. After the reaction, it was filtered, and the obtained filtrate was dried at 80° C. to obtain solid powder of calcium phosphate salt.

[0042] The calcium phosphate salt solid powder is mixed with acetone at a volume ratio of 1:3, washed, and the calcium phosphate salt product and washing liquid are obtained after solid-liquid separation. The calcium phosphate product is distilled to recover acetone to obtain a feed-grade calcium phosphate product, and the washing liquid is distilled to recover acetone to obtain purified phosphoric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com