A kind of preparation method of two-dimensional manganese iodide material

A technology of manganese iodide and transfer equipment, which is applied in the field of two-dimensional materials and multiferroic materials, can solve the problems of difficult application, unevenness, and small sample size, and achieve commercial development, simple operation, and easy control of conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

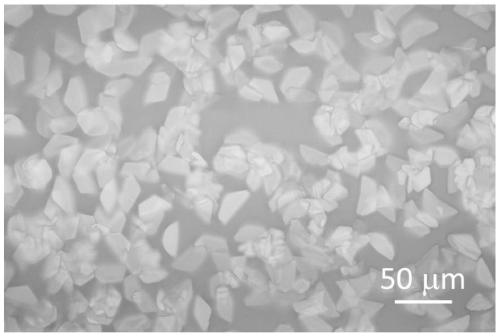

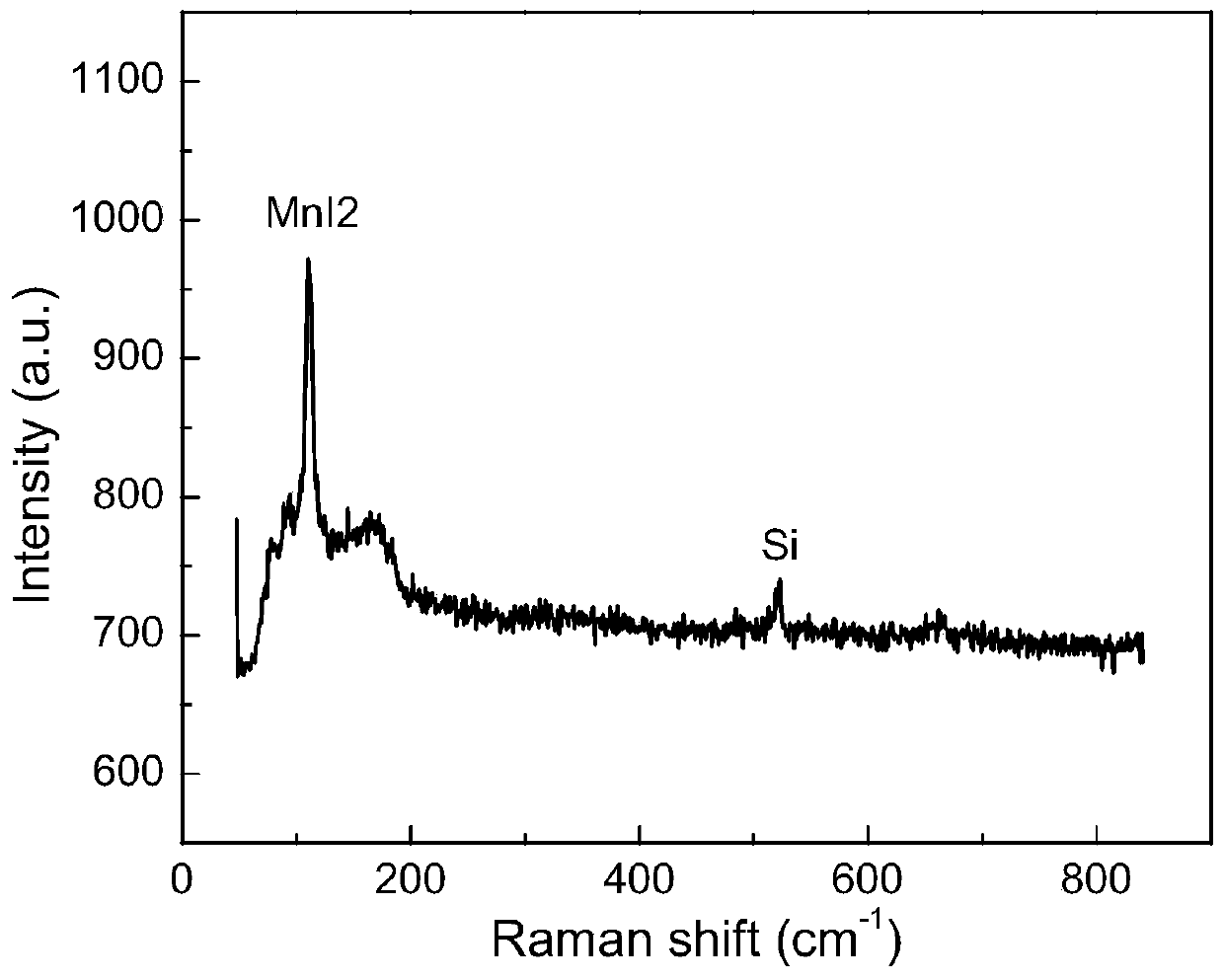

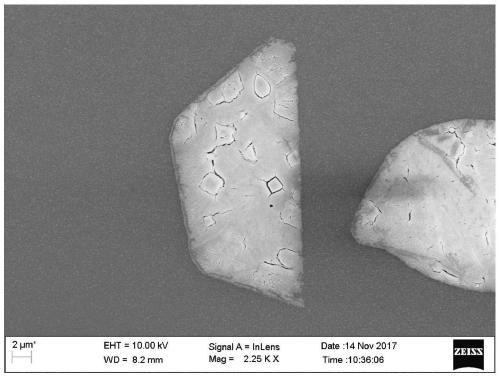

[0037] Step 1. Wipe a short glass tube with a diameter of 8mm and a length of 200mm with alcohol and dry it; place a 20mm×5mm×0.1mm silicon chip in Clean the beaker with a mixed solution of ethanol, acetone and isopropanol ultrasonically for 20 minutes, then rinse it with deionized water for 3 times, and use N with a purity (volume fraction) of not less than 99.999%. 2 Blow dry; put 0.3g of manganese iodide powder and silicon chip after ultrasonic cleaning into the short glass tube after wiping with alcohol, the manganese iodide powder is at one end of the short glass tube, the distance between the silicon chip and the manganese iodide powder Then put the short glass tube into the furnace tube of the dual temperature zone CVD tube furnace. The manganese iodide powder is located in the center of the first temperature zone, and the end of the second temperature zone far away from the silicon wafer is put into the furnace plug, close to the first temperature zone. One end of the ...

Embodiment 2

[0042] Step 1. Wipe a short glass tube with a diameter of 5.5mm and a length of 240mm with alcohol and dry it; place a 20mm×5mm×0.1mm silicon wafer After ultrasonic cleaning in a beaker of a mixed solution of ethanol, acetone and isopropanol for 15 minutes, rinse it with deionized water for 5 times, and use N with a purity (volume fraction) of not less than 99.999% 2 Blow dry and blow dry; put 0.6g of manganese iodide powder and ultrasonically cleaned silicon chip into a short glass tube wiped with alcohol, the manganese iodide powder is at one end of the short glass tube, between the silicon chip and the manganese iodide powder The distance is 140mm; then put the short glass tube into the furnace tube of the dual temperature zone CVD tube furnace, the manganese iodide powder is located in the center of the first temperature zone, and the end of the second temperature zone far away from the silicon wafer is put into the furnace plug, close to One end of the furnace tube in the...

Embodiment 3

[0047] Step 1. Wipe a short glass tube with a diameter of 15mm and a length of 160mm with open ends with alcohol and dry it; place a 20mm×5mm×0.1mm silicon wafer in a Clean the beaker with a mixed solution of ethanol, acetone and isopropanol ultrasonically for 30 minutes, rinse it with deionized water three times, and use N with a purity (volume fraction) of not less than 99.999%. 2 Blow dry and blow dry; put 0.1g of manganese iodide powder and ultrasonically cleaned silicon chip into a short glass tube wiped with alcohol, the manganese iodide powder is at one end of the short glass tube, between the silicon chip and the manganese iodide powder The distance is 70mm; then put the short glass tube into the furnace tube of the dual-temperature zone CVD tube furnace, the manganese iodide powder is located in the center of the first temperature zone, and the end of the second temperature zone far away from the silicon wafer is put into the furnace plug, close to One end of the furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com