Suspended non-metal fast inserting panel

A non-metallic and plate-mounting technology, which is applied in the field of architectural decoration, can solve the problems of large construction costs, difficulty in leveling, and cumbersome construction techniques, and achieve the effects of convenient maintenance and upgrading, reducing the impact of product quality, and improving technical quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

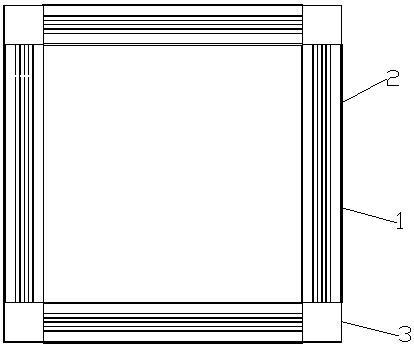

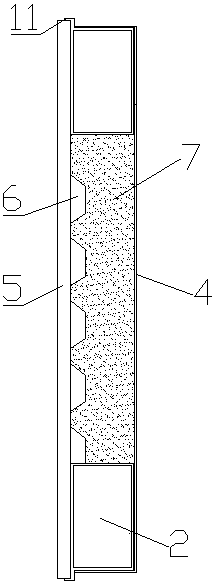

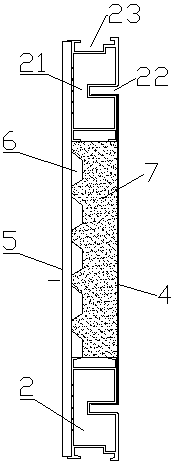

[0016] In one of the embodiments, such as figure 1 and figure 2 A hanging non-metallic quick-loading plate shown has a keel frame 1, the keel frame 1 is composed of horizontally and vertically arranged keel frame frames 2 spliced end to end, and each keel frame frame 2 is connected by a corner connector 3 ; The front side of the keel frame 1 is pasted with a non-metallic plate 4, the back of the keel frame 1 is pasted with a color-coated steel plate 5, the non-metallic plate 4 arranged on the front side of the keel frame 1 and the non-metallic plate 4 arranged on the back of the keel frame 1 The hollow space 6 formed between the color-coated steel plates 5 is pasted with metal or non-metallic lightweight fillers 7, and the outer side of the keel frame 1 is provided with an installation for accurately placing the color-coated steel plates 5. Benchma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com