Dust detection apparatus having rapid clamping jig

A dust detection and fast technology, applied in the field of sensors, can solve the problems of troublesome removal, affecting the connection speed, and easy damage of metal probes, etc., and achieves the effects of convenient installation and disassembly, improved installation flexibility, and stable conversion data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

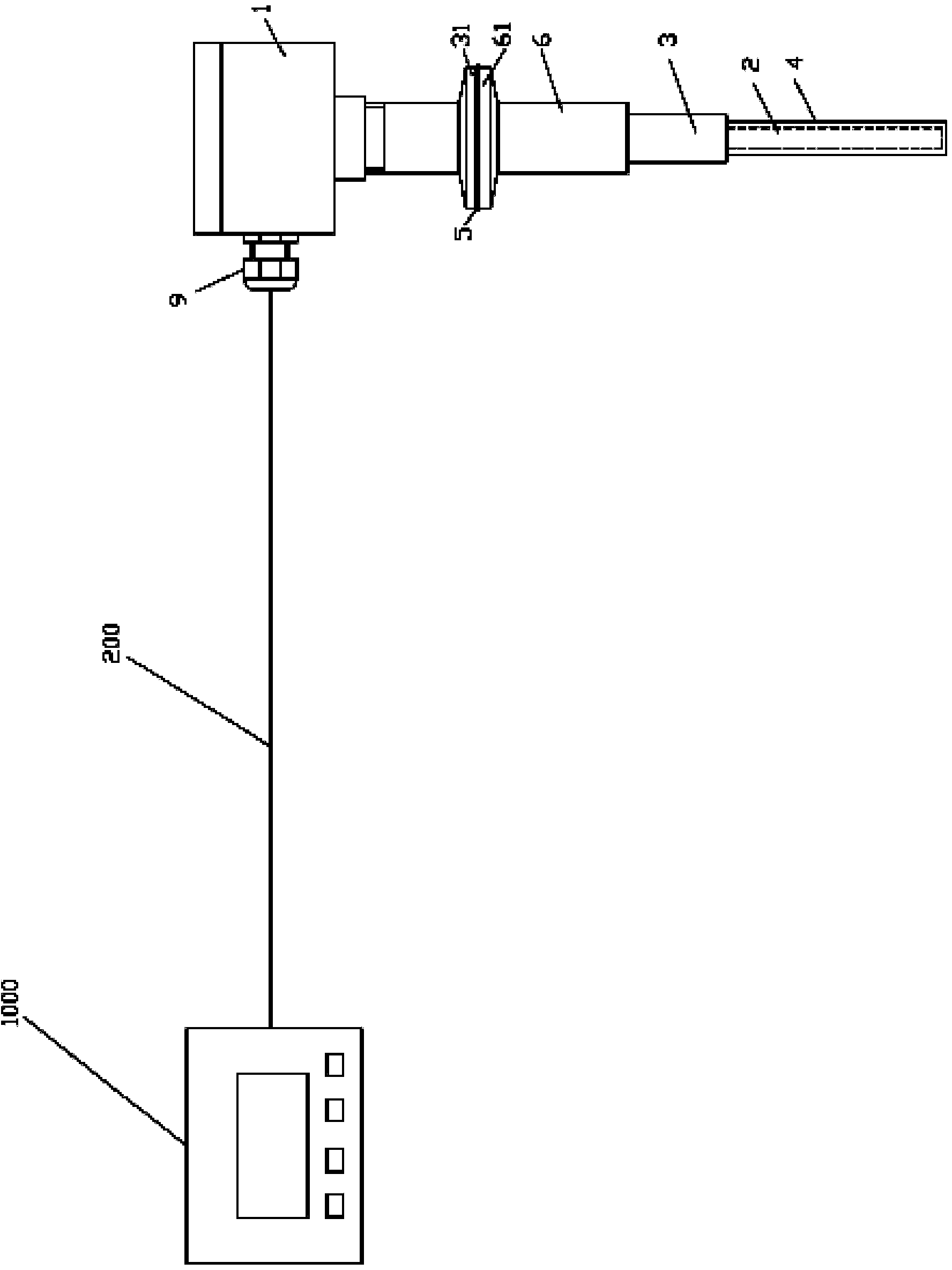

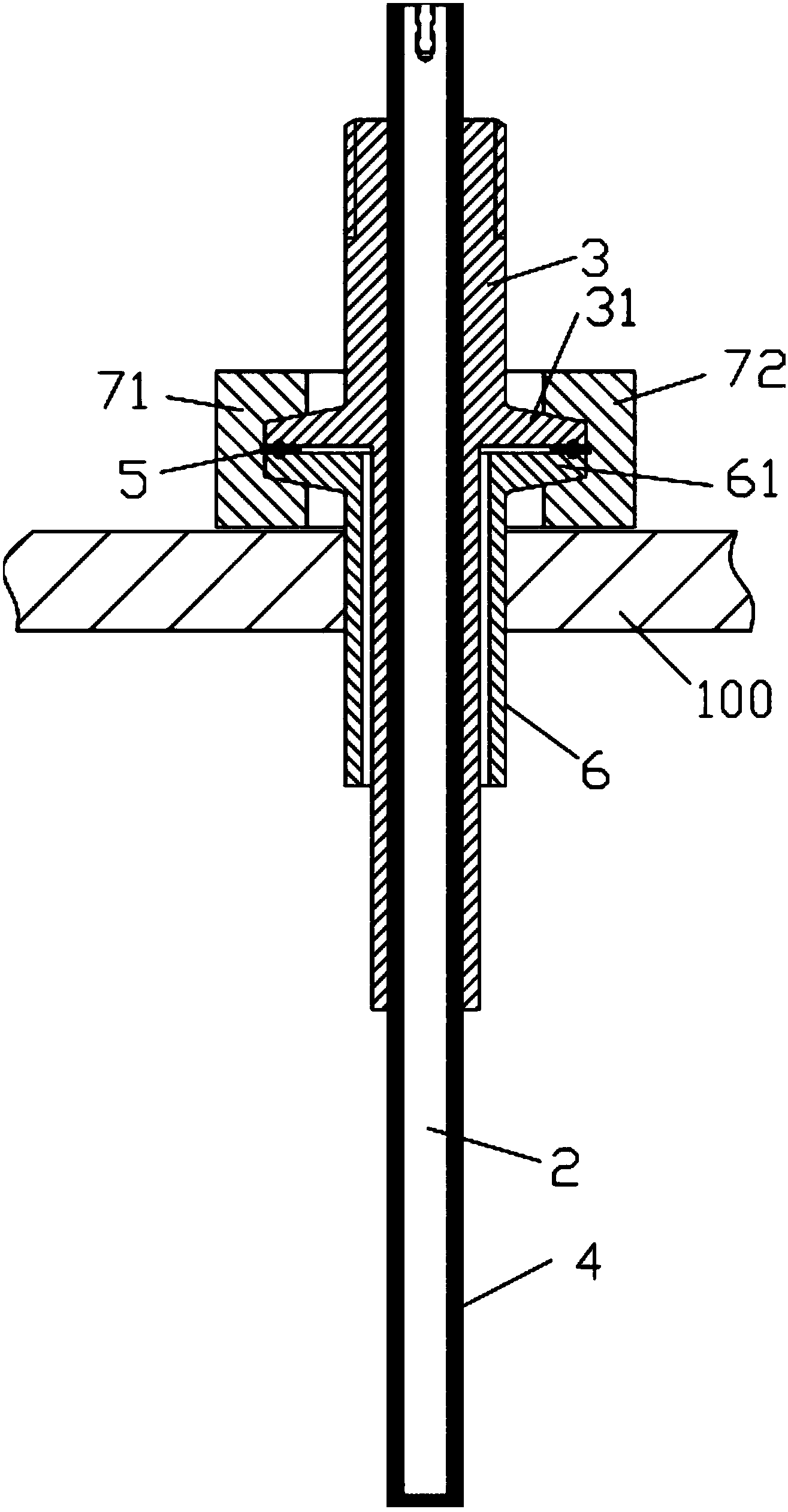

[0035] Examples, see e.g. Figures 1 to 10 As shown, a dust detection device with a quick clamping fixture includes a controller 1000, a signal line 200, a probe box 1 and a metal rod 2, the controller 1000 is connected to the metal rod 2 through the signal wire 200, and the metal rod 2 is fixed in the connecting sleeve 3 (it can be fixed by sticking or clamping), the lower end of the metal rod 2 protrudes from the lower end of the connecting sleeve 3, and the part of the metal rod 2 protrudes from the lower end of the connecting sleeve 3 For the sensing part, at least the surface of the sensing part is coated with a Teflon material layer 4, the upper end of the connecting sleeve 3 is screwed into the raised block at the bottom of the probe box 1, and the metal rod 2 protrudes from the upper end of the connecting sleeve 3 A part of it is inserted into the probe box 1;

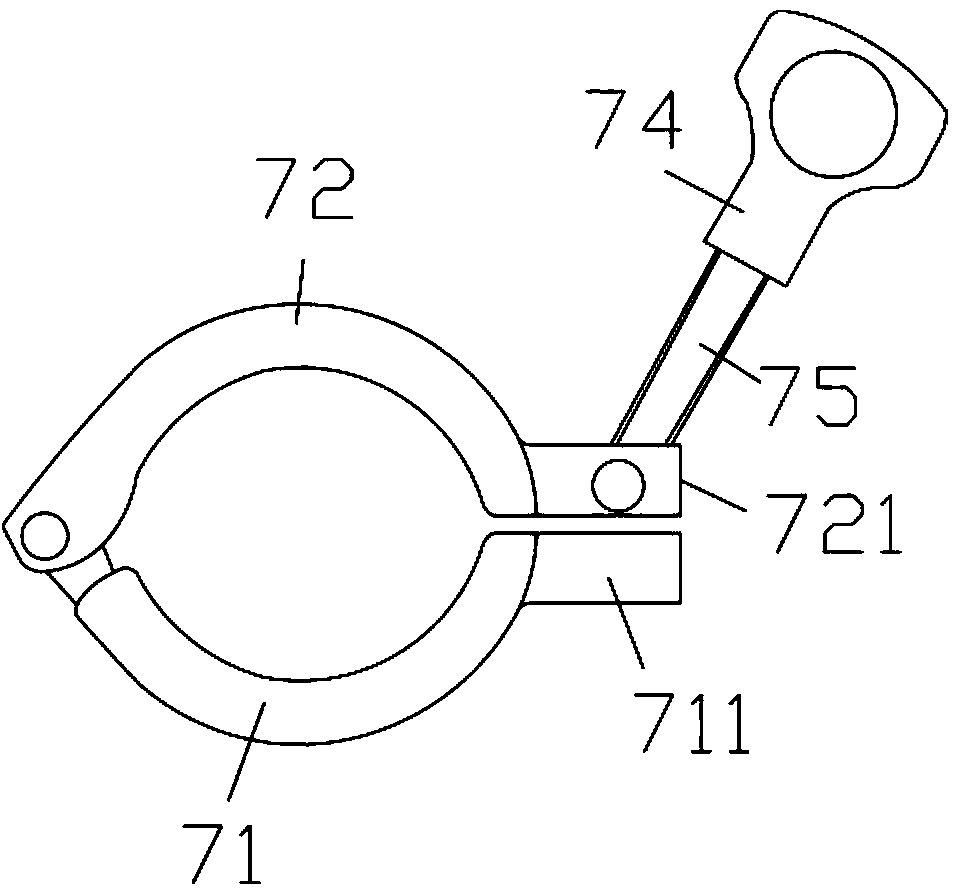

[0036] The outer wall of the middle part of the connecting sleeve 3 is formed with a radially extending upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com