Plastic flat plate heat collector

A flat plate heat collector and plastic technology, which is applied to solar heat collectors, solar heat collectors using working fluids, heating devices, etc., can solve the problems of high manufacturing cost, poor thermal conductivity, and overall weight, and reduce manufacturing costs. , the overall weight reduction, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

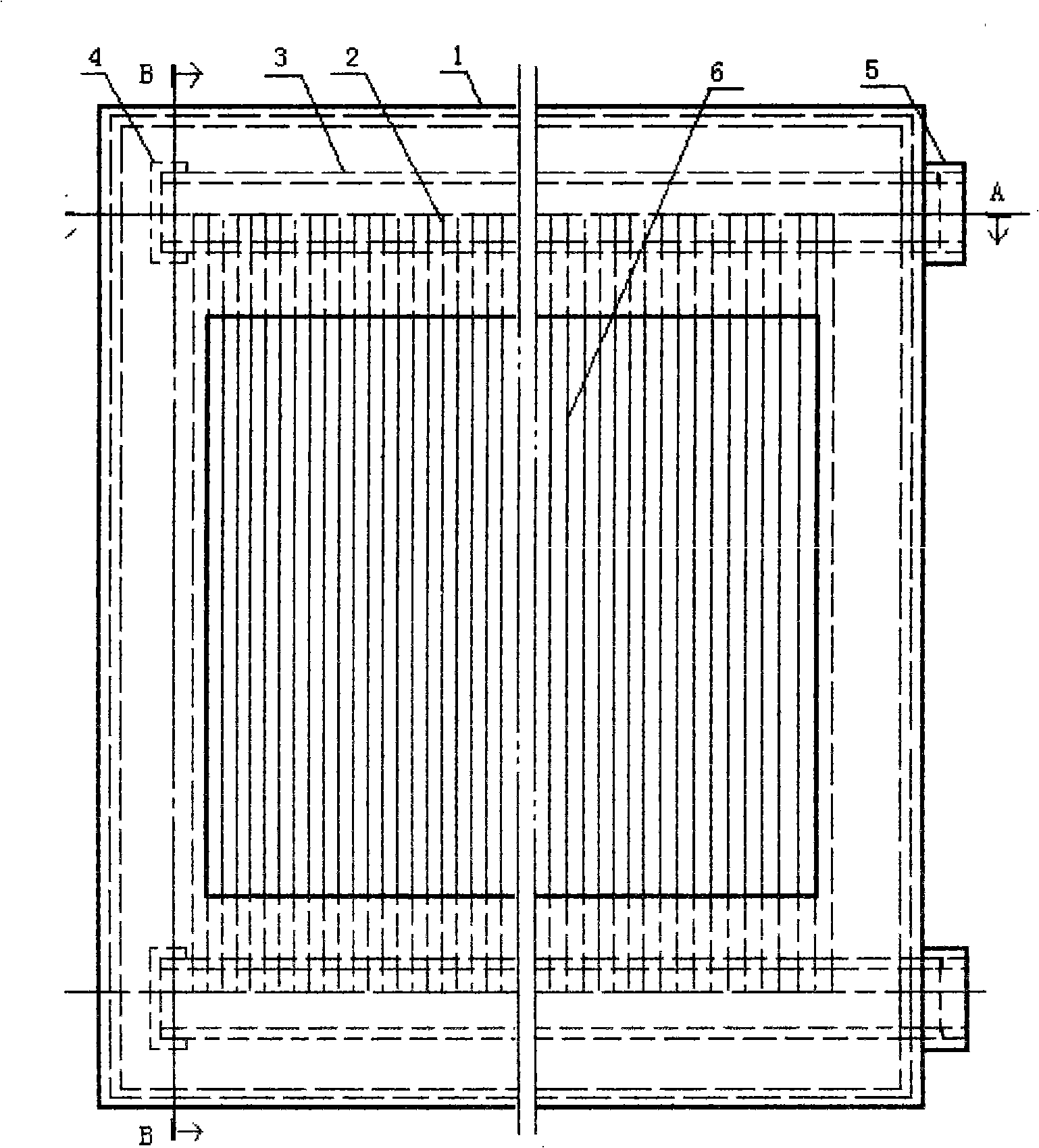

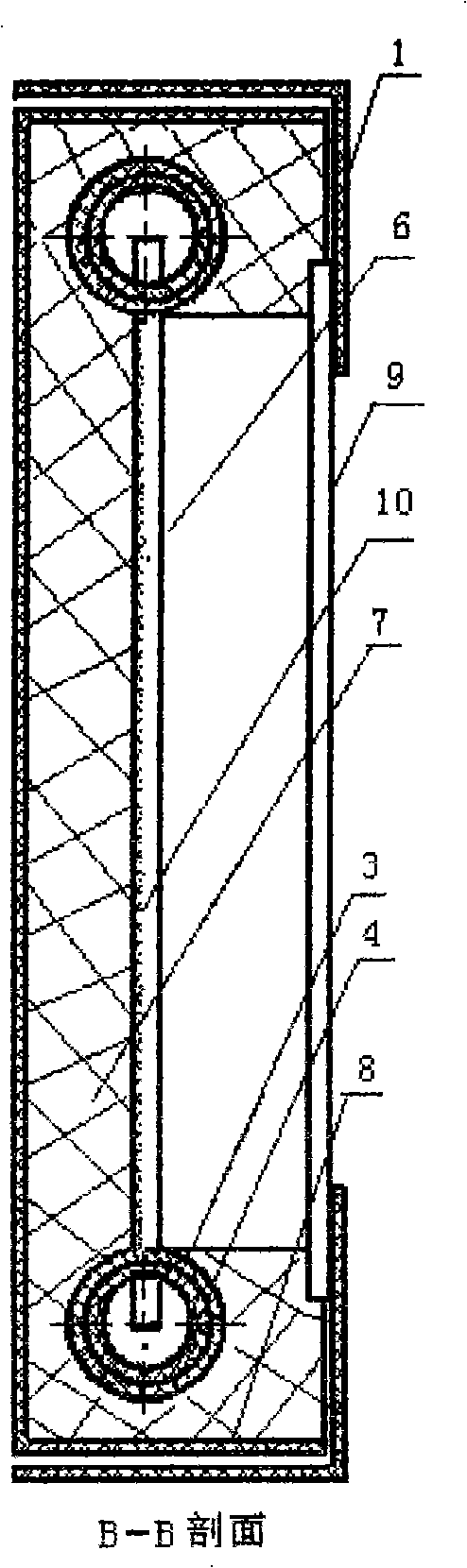

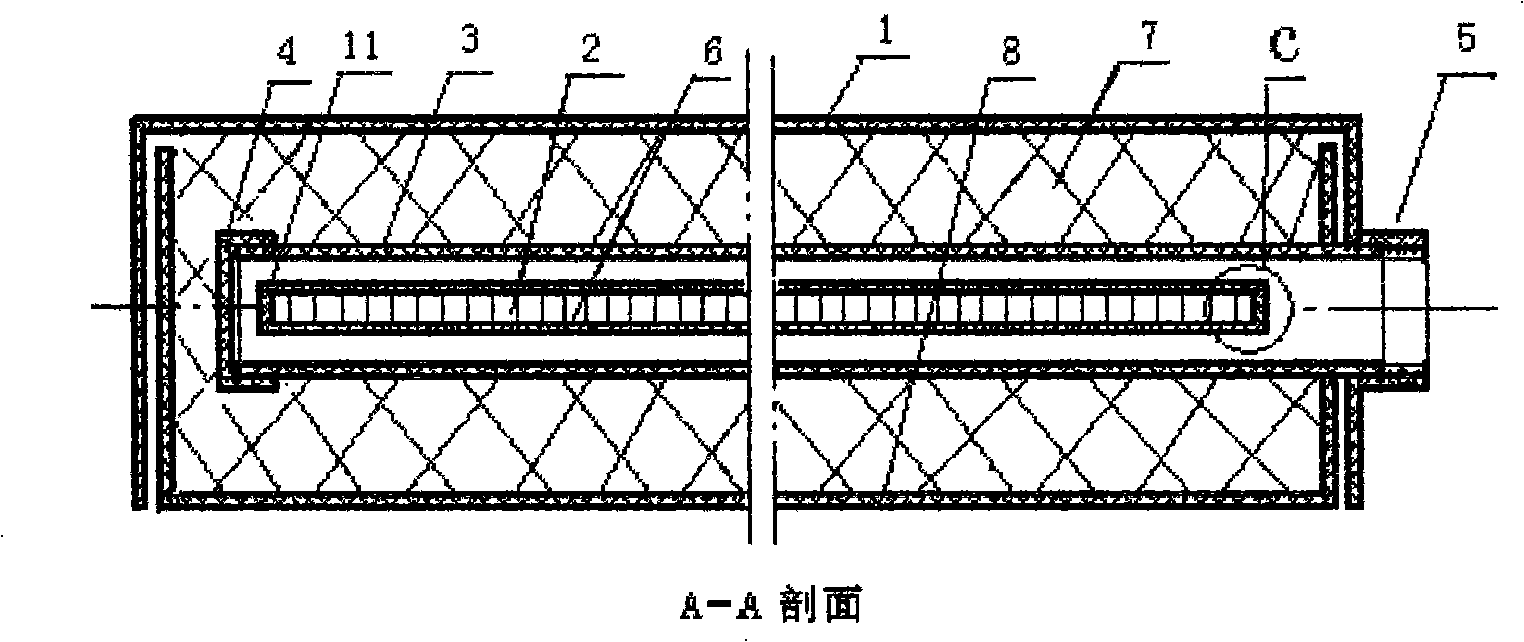

[0011] The first choice is to make a plastic flat collector shell 8 similar to a square box by injection molding, and plastic materials can also be assembled into a plastic flat collector shell 8 by bonding, and the insulating layer 7 is formed by filling light insulating materials inside. Transparent and water-resistant, temperature-resistant, weather-resistant plastic is used to make a hollow transparent plastic sheet with multiple small drainage pipes 2 through extrusion molding, and the inner wall of the small drainage pipe is coated with solar selective absorption. Coating 10 just becomes plastics row pipe heat-absorbing plate 6. Use plastic pipes with good temperature resistance, water resistance and weather resistance as the collecting pipe 3, use plastic plug 4 to heat-melt and seal one nozzle, and the other nozzle is thermally welded with inner wire 5 as the interface of the external heating part. On the plastic collecting pipe 3, a connection groove 11 is melted out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com