Equipment and method for controlling accuracy of sticking of wall tile and caulked joint

A technology of wall bricks and equipment, which is applied in the direction of construction and building construction, and can solve problems such as uneven mortar joints, sinking of facing bricks, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

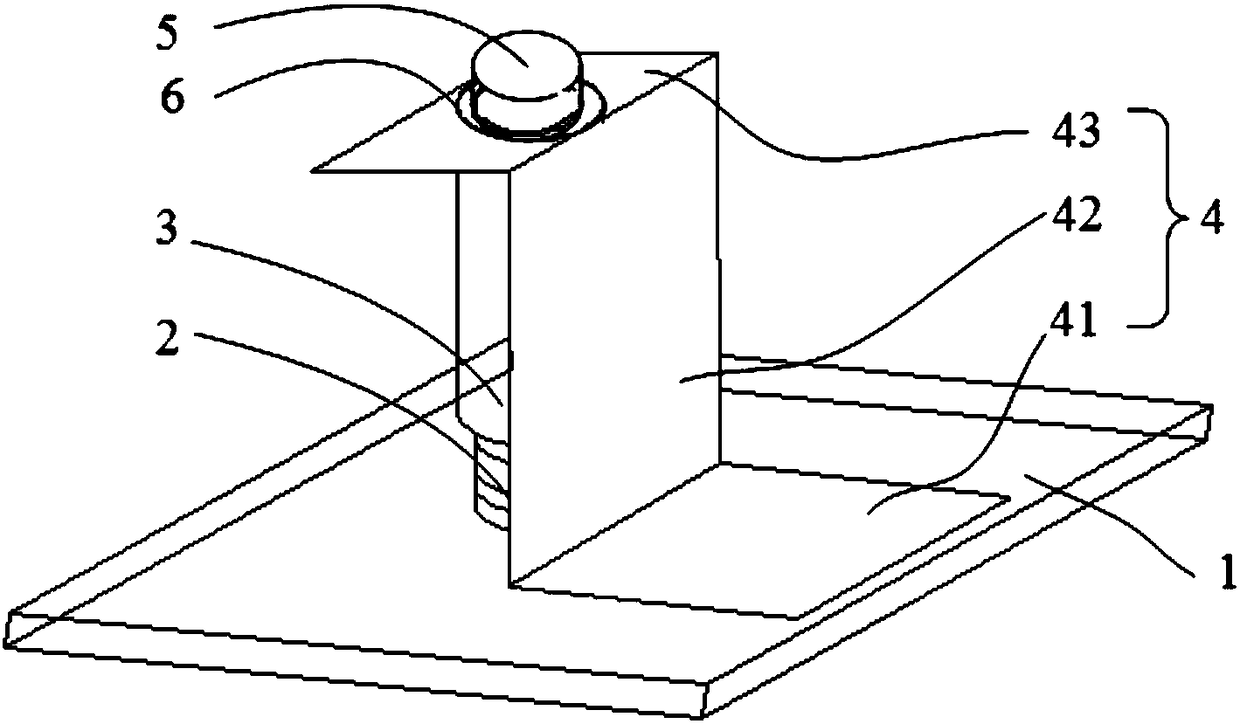

[0042] Such as figure 1 As shown, this embodiment provides a device for controlling the accuracy of wall tile inlay and caulking, including a chassis 1, an adjustment shaft 2, an adjustment tube 3, a strut sheet 4 and a fixing member 5; the lower end of the adjustment shaft 2 Vertically and fixedly connected to the chassis 1, the adjusting tube 3 is sleeved on the adjusting shaft 2 and screwed to it, the upper end of the adjusting tube 3 is fixedly connected with the fixing piece 5, and the upper end of the strut piece 4 is rotatably installed on the adjusting tube 3 and the fixing piece 5 Between them, a first horizontal piece 41 is formed at the lower end of the strut piece 4 for horizontally supporting the spacer.

[0043] Preferably, the upper end of the strut piece 4 is provided with a mounting hole, the fixing member 5 is a bolt, and the bolt passes through the mounting hole and is threadedly connected with the upper end of the adjusting tube 3 with internal threads, and...

Embodiment 2

[0050] This embodiment provides a method for controlling the accuracy of wall tile inlaying and caulking. This embodiment uses the equipment in Embodiment 1, which has all the technical features and beneficial effects in Embodiment 1, including the following steps:

[0051] S1, place the equipment at both ends of the front side of the wall that needs to be inlaid with wall tiles, according to the length of the wall, do not add or add some equipment between the two ends of the equipment, and place the spacer on the first horizontal sheet 41 of all equipment superior;

[0052] S2, use a spirit level to detect the levelness of the pad, and adjust the height of the first level sheet 41 by rotating the adjustment tube 3 of each device according to the detection result until the pad reaches the level;

[0053] S3, first inlay two rows of wall tiles on the left and right sides of the wall from bottom to top, then inlay a row of wall tiles below the wall along the spacer, and then inl...

Embodiment 3

[0068] Such as figure 1 As shown, this embodiment provides a device for controlling the accuracy of wall tile inlay and caulking, including a chassis 1, an adjustment shaft 2, an adjustment tube 3, a strut sheet 4 and a fixing member 5; the lower end of the adjustment shaft 2 Vertically and fixedly connected to the chassis 1, the adjusting tube 3 is sleeved on the adjusting shaft 2 and screwed to it, the upper end of the adjusting tube 3 is fixedly connected with the fixing piece 5, and the upper end of the strut piece 4 is rotatably installed on the adjusting tube 3 and the fixing piece 5 Between them, a first horizontal piece 41 is formed at the lower end of the strut piece 4 for horizontally supporting the spacer.

[0069] Preferably, the lower end of the adjustment shaft 2 is welded to the base, and the chassis 1 is placed on the ground by setting the chassis 1 to provide a stable support foundation for the equipment; the adjustment shaft 2 connected to the chassis 1 by ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com