A kind of suction pump and washing machine

A technology of suction pump and suction chamber, applied to other washing machines, pumps, pump components, etc., can solve the problems of complicated structure of suction pump, and achieve the effect of simple structure, high reliability and avoiding water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

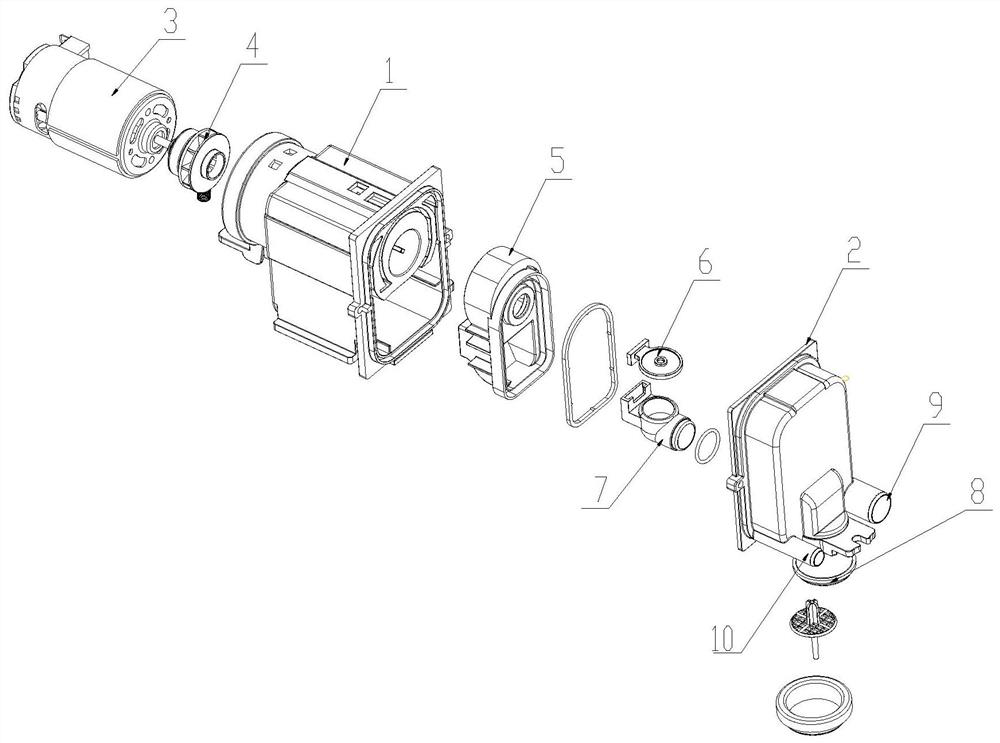

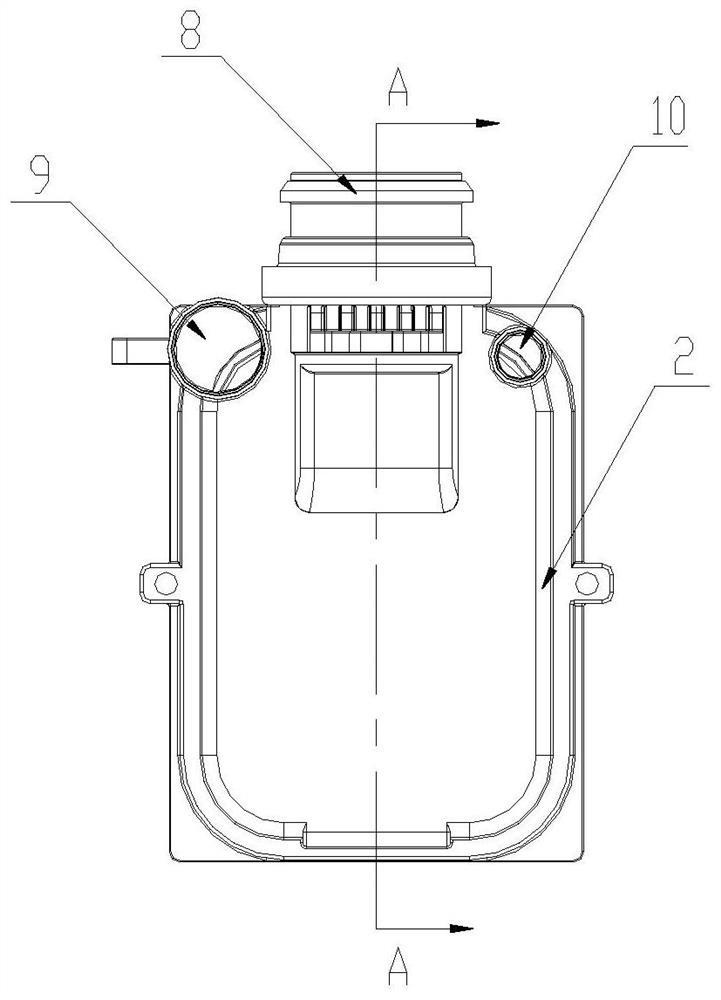

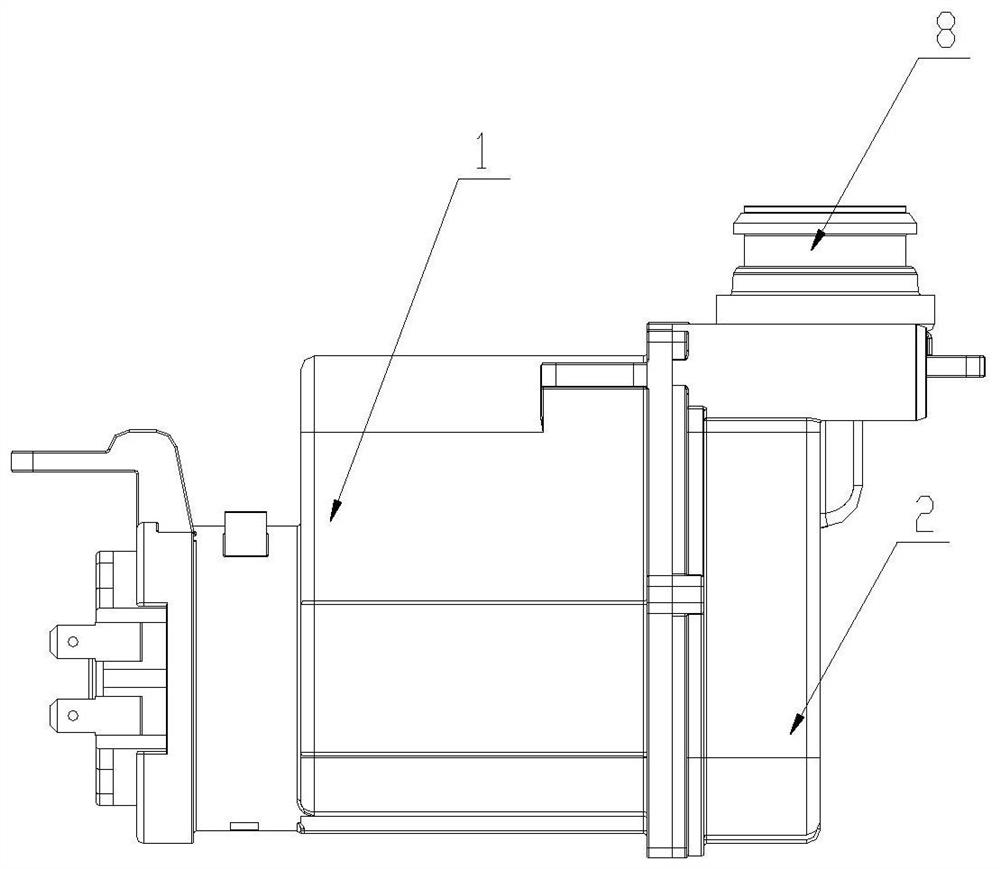

[0046] Such as Figure 1-12 As shown, the diversion mechanism includes a diversion tube 701, one end of the diversion tube 701 is connected to the water suction port 8, and the other end is a water outlet; the one-way non-return mechanism is arranged in cooperation with the water outlet of the diversion tube , which is used to make the water flow enter the water suction chamber in one direction from the guide tube.

[0047] At present, the one-way valve of some water suction pumps is arranged in the water suction port, and the one-way valve is in sealing contact with the water suction port, so that the water flow passes through in one direction. But in this way, the one-way valve must be set according to the structure of the water suction port, and the impact pressure of the water received is relatively large, which is prone to deformation and poor sealing.

[0048] One end of the diversion pipe in this embodiment is connected to the water suction port for communicating with ...

Embodiment 2

[0059] The one-way stop mechanism described in this embodiment includes a valve plate 11 and an elastic member 14. One side of the valve plate 11 is in sealing contact with the water outlet of the draft pipe 701, and the other side is provided with an elastic member 14. The other side of the elastic member 14 is in sealing contact with One end stops against the inner wall of the water-absorbing chamber 13 .

[0060] The one-way check mechanism in this embodiment is a one-way check valve, which includes a valve plate for blocking the water outlet of the diversion pipe and an elastic member for pressing the valve plate. The elastic member may be a spring. The spring on one side of the valve plate is against the inner wall of the water-absorbing chamber, so that the valve plate can be pressed tightly against the water outlet of the draft tube for sealing contact.

[0061] The valve plate can be set as an elastic sheet whose shape matches the water outlet of the diversion pipe; on...

Embodiment 3

[0068] This embodiment is a further limitation of the above-mentioned embodiment. The outer wall of the guide tube is provided with a connection part 702 for fixing the one-way check mechanism, and the valve plate of the one-way check mechanism is provided with a With the matching tail part 111 , the one-way non-return mechanism is fixedly connected with the guide tube 701 through the tail part 111 .

[0069] The one-way check mechanism is fixedly connected with the diversion mechanism. The diversion pipe is installed in the accommodation chamber on the upper part of the water suction chamber cover, and the outer wall of the diversion pipe is provided with a connecting part protruding outward and downward, and the connecting part is lower than the water outlet of the diversion pipe downward, which is convenient for connection with valve connection.

[0070] The valve plate of the one-way check mechanism is a circular sheet with a diameter not smaller than the water outlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com