Rolling wheel connecting shaft

A technology for connecting shafts and rollers, applied in the direction of couplings, elastic couplings, shafts, etc., can solve the problems of difficult disassembly, troublesome use, abnormal wear and so on, and achieve the effects of convenient use, easy operation and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

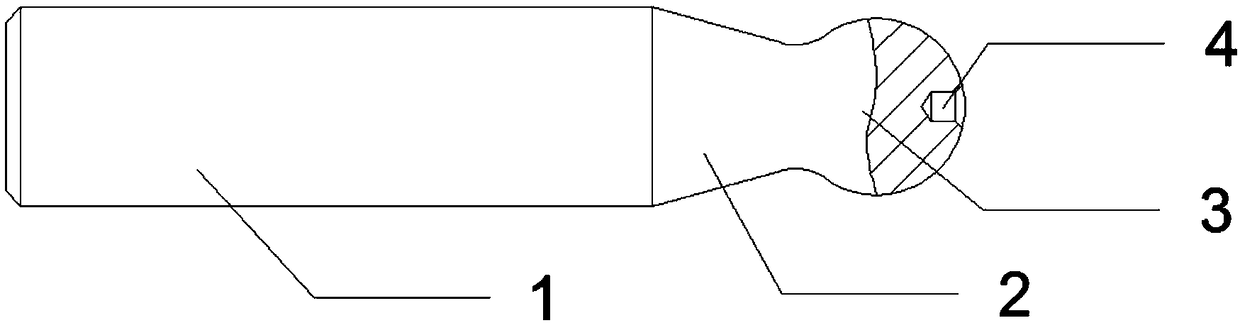

[0015] Embodiment: A roller coupling shaft, which is divided into a cylindrical shaft 1, a cone 2, a sphere 3, and a central hole 4. The overall length of the connecting shaft is 45.1mm-45.3mm, one end is a cylindrical shaft 1, and the end surface of the cylindrical shaft is 0.65mm-0.75 45° chamfering of mm, the diameter of cylinder shaft 1 is 9.65mm-9.67mm, and the surface roughness is 1.6, the other end of the connecting shaft is sphere 3, the diameter of sphere 3 is 8.2mm-8.3mm, and the surface roughness is 3.2. The transition shape between the cylindrical axis 1 and the sphere 3 is a cone 2, the slope of the cone 2 is 13°-17°, the joint is a circular chamfer with a radius of 2.5mm, and the surface roughness is 3.2. A center hole 4 with a diameter of 1.95mm-2.05mm is provided on the top of the ball 3; the center hole on the surface of the ball head is processed by A1.5 center drilling; heat treatment is also required: carburizing, quenching, and tempering.

[0016] To sum u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com